How Double Jacquard Machine Brings Intricate Designs to Life

In the world of warp knitting, precision and pattern diversity are key to staying competitive. One machine stands out in enabling this: the Double Jacquard Machine. Known for its ability to create complex, multi-layered fabric designs, it is a revolutionary tool in textile manufacturing. At Grand Star, we specialize in developing and producing cutting-edge machines like the Double-Jacquard Raschel RJPC 4/2F, a high-performance solution engineered for versatility and reliability. Let’s explore how our technology turns creative concepts into intricate, high-quality fabrics.

Why Double Jacquard Raschel RJPC 4/2F Machine Unique?

The Double Jacquard Machine is designed to support detailed and elaborate fabric constructions. With a working width of 4318 mm (170 inches) and gauges available in E18 and E24, it supports a wide range of fabric weights and densities. This allows manufacturers to meet diverse customer demands from fashion to upholstery.

Key Advantages

✅Dual-layer patterning for enhanced texture and depth

✅High gauge precision for smooth and fine surface finishes

✅Consistent performance even in large-scale production

Unlike standard warp knitting machines, the double Jacquard system offers electronic control over both the ground and Jacquard guide bars, enabling exceptional control and flexibility in design.

Electronically Controlled Patterning for Superior Output

EL Pattern Device Technology

Our Electronically controlled EL system manages both ground and Jacquard bars to deliver consistent, intricate patterning across fabric runs. Whether you’re working with floral, geometric, or abstract designs, the EL system ensures accuracy at every level.

✅Reduces manual intervention

✅Allows real-time design adjustments

✅Ideal for high-mix, low-volume production

This technology ensures that every fabric roll is not only beautiful but also reproducible – a key requirement for modern manufacturers.

Grand Star® Command System: Designed for Operators

At Grand Star, we believe that advanced technology should be powerful – but also practical. That’s why we created the Grand Star® Command System, an intuitive, operator-friendly interface that puts full control of the Double Jacquard Machine at your fingertips.

This integrated control platform is designed to simplify the daily operation of complex warp knitting machinery. From initial setup to real-time production adjustments, everything is accessible through a clean, logical interface. Operators can quickly configure:

✅Yarn let-off speeds

✅Guide bar coordination and movement

✅Pattern sequence settings

✅Production monitoring and diagnostics

The result? Faster start-ups, fewer errors, and smoother transitions between fabric types and patterns. Even operators with minimal experience can quickly learn and navigate the system with ease. Because we know that time is money, the Grand Star® Command System is built to reduce setup times and training hours, while boosting productivity across every shift. Its user-friendly design helps avoid costly downtime and supports consistent, high-quality output. We’ve designed this system not just for engineers, but for the people who run our machines every day – because technology should empower your team, not stand in their way.

Efficient Yarn Handling & Take-Up Mechanism

Smooth yarn handling is essential for the production of high-quality, intricately patterned fabrics. The Double Jacquard Machine is equipped with advanced systems that ensure consistent yarn flow, tension stability, and flawless fabric winding – all critical for maintaining pattern accuracy and reducing waste.

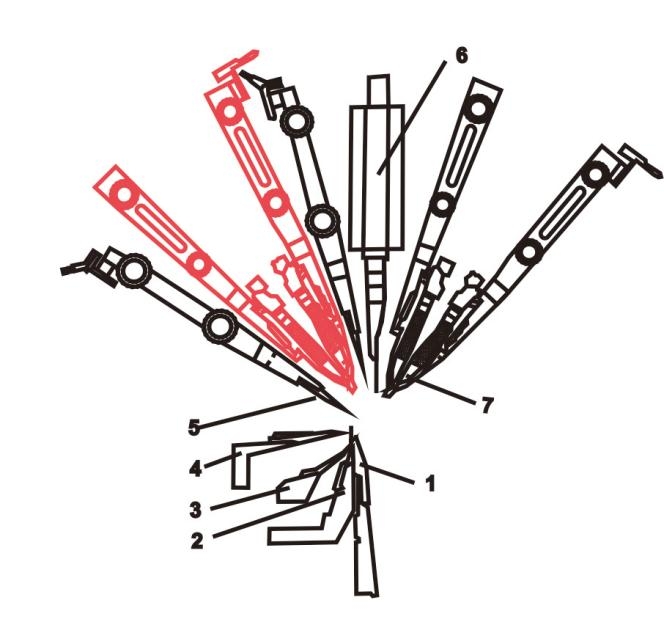

1) Advanced Yarn Let-Off System

Our machine features three independently controlled electric let-off devices for the ground guide bars. Each controller supports multiple-speed settings, allowing operators to precisely manage yarn tension across different fabric zones. This ensures:

✅Accurate feeding of yarns across all layers

✅Minimized yarn breakage or slippage

✅Improved control over complex designs

With this system, even the most delicate patterns are reproduced with clarity and consistency – reducing defects and enhancing production speed.

2) Automated Fabric Take-Up System

Efficient fabric collection is just as important as the knitting process itself. That’s why the Double Jacquard Machine includes a fully automated take-up mechanism with:

•Four high-durability rollers for steady traction

•Black rubberized surfaces that prevent slippage

•Perforated roller design paired with a reliable gear motor

This setup ensures that finished fabrics are evenly wound without pulling, stretching, or distorting the intricate patterns. The result? Perfectly tensioned, roll-ready fabric with every run.

Applications: Where Intricate Designs Matter

Thanks to its unmatched precision, the Double Jacquard Machine finds applications in a wide range of industries where design complexity and texture are key:

•Home Textiles – From elegant curtains to richly patterned tablecloths, this machine adds luxury to everyday living spaces.

•Apparel – Ideal for creating fashionable garments, lingerie, and lace with fine detail and high comfort.

•Automotive Interiors – Delivers stylish, durable upholstery and functional interior fabrics with customized textures.

•Medical & Sports Fabrics – Supports structural knitting for performance wear, compression gear, and orthopedic textiles.

Whether you’re designing for comfort, beauty, or performance, the Double Jacquard Machine provides the flexibility and accuracy your business needs.

Who We Are – Grand Star

At Fujian Grand Star, we go beyond manufacturing – we deliver innovative textile solutions tailored for the future of warp knitting. Since our founding in 2012, we’ve been committed to advancing the textile machinery industry through cutting-edge engineering, smart control systems, and responsive customer support. Headquartered in Fuzhou, China, our company brings together a passionate team of over 50 experienced professionals specializing in the design, research, and production of high-performance warp knitting machines. Every machine we build – including our advanced Double Jacquard Machine – reflects our dedication to precision, reliability, and usability.

What sets Grand Star apart is our focus on customer-driven innovation. We listen to what textile manufacturers need – greater efficiency, flexibility, and design control – and translate those needs into real-world features that boost productivity and product quality. We know that in today’s competitive textile market, your success relies on more than just hardware. It requires a partner that delivers consistent quality, long-term performance, and smart innovation. That’s why every solution we provide is built with your business goals in mind. At Grand Star, we’re proud to help manufacturers around the world bring complex designs to life – efficiently, beautifully, and at scale.

Final Thoughts

The demand for intricate, high-quality textiles is growing. With the Double Jacquard Machine from Grand Star, you gain a reliable partner in turning patterns into performance. From technical specs to real-world application, this machine is built to bring your creative vision to life. Contact us today to learn more about how our Double Jacquard Machine can elevate your production – and your business.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.