What Are the Best Features in Tricot Machines for Sale That You Can’t Miss?

When searching for a Tricot Machine for Sale, it’s essential to focus on the key features that best suit your fabric production needs. Tricot machines are highly regarded in the textile industry for their precision, flexibility, and efficiency, making them a popular choice for manufacturers across various sectors. But with so many options available, how do you ensure you’re selecting the right machine for your production requirements? In this article, we’ll guide you through the critical features you should look for in a Tricot Machine for Sale, helping you make an informed purchasing decision.

Versatility Across Different Fabric Applications

One of the main advantages of a Tricot Machine for Sale is its remarkable versatility. These machines can handle a wide variety of fabrics, making them suitable for numerous industries, from automotive textiles to fashion, home decor, and technical fabrics. Tricot machines come with different configurations of guide bars, which make them adaptable for different fabric types and production needs. Here’s a breakdown:

✅ Guide Bar Configurations

- 2 Guide Bars: Perfect for lightweight fabrics such as mosquito nets, bedding, and even advertising media materials.

- 3 Guide Bars: Best for more specialized fabrics, including automotive textiles, upholstery, and sportswear that require enhanced performance.

- 4 Guide Bars: Designed for intricate, plush fabrics, ideal for premium upholstery, shoe textiles, and durable cleaning cloths.

These adaptable guide bar configurations allow manufacturers to easily switch between different fabric types, minimizing the need for multiple machines. This not only saves on production space but also optimizes investment costs.

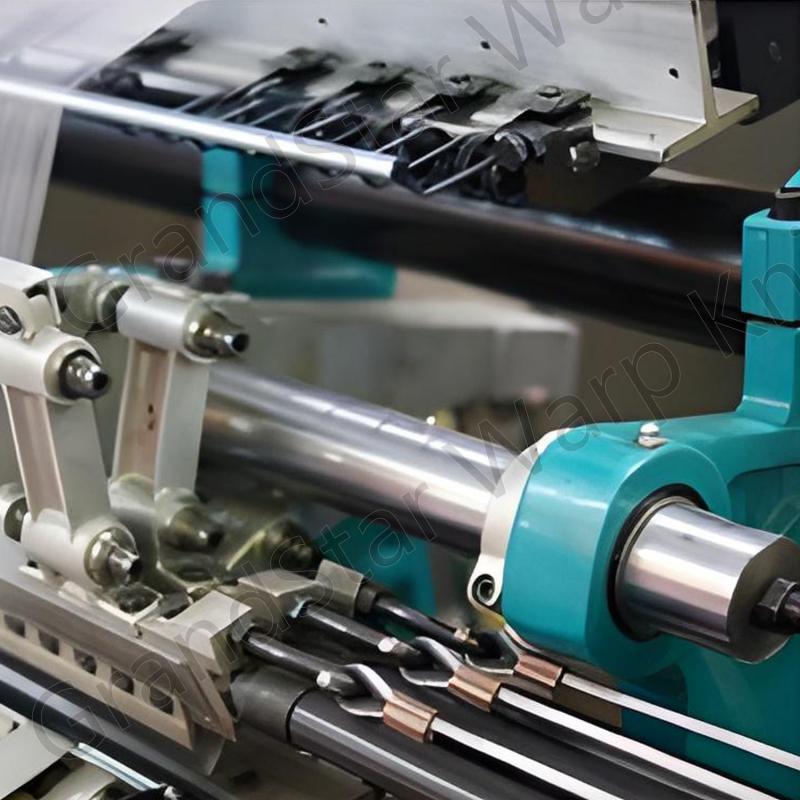

Precision Engineering for Superior Fabric Production

A Tricot Machine for Sale is designed for precision, ensuring that your fabric is produced with high consistency and quality. When you invest in one of these machines, you’re not just acquiring a tool but a reliable partner in your production line. Below are the key features that contribute to the efficiency and precision of tricot machines:

- Advanced Needle System and Shogging Mechanism

Tricot machines feature advanced needle bar systems, along with compound needles that allow for high levels of control in fabric formation. This advanced design ensures that each fabric produced is precise in its texture and quality. The shogging mechanism, which controls the movement of guide bars, enables manufacturers to produce a variety of fabric patterns and surface textures. This versatility makes the tricot machine perfect for fashion textiles, upholstery, and technical fabrics.

- Integrated Monitoring Systems

Modern Tricot Machines for Sale come with integrated laser stop systems and cameras that monitor fabric production in real time. This means that if any defects or issues are detected, the machine halts automatically, preventing waste and ensuring that only the highest-quality fabric is produced. With this feature, you can easily maintain strict quality control standards, helping to reduce errors and improve overall production efficiency.

- Fabric Take-Up and Let-Off Systems

To maintain optimal fabric tension, modern tricot machines are equipped with advanced fabric take-up and let-off systems. These systems ensure that your fabric is produced with the correct amount of stretch and density, which is essential for fabrics used in sportswear, automotive interiors, or any application that requires precise fabric properties. By maintaining consistent tension throughout the knitting process, the fabric quality is ensured every time.

Energy Efficiency for Cost Savings and Sustainability

One of the most important considerations when choosing a Tricot Machine for Sale is energy efficiency. With rising energy costs, it’s essential to select a machine that not only meets your production needs but also helps you cut down on operational costs. Modern tricot machines are designed with energy-saving technologies, which result in lower energy consumption without compromising on performance.

- Speed-Regulated Drive System

The speed-regulated drive system in many tricot machines helps to control energy usage by adjusting the machine’s speed according to production demands. This reduces unnecessary energy consumption, making the machine more eco-friendly and cost-effective.

- Environmentally Friendly Manufacturing

By opting for energy-efficient tricot machines, you’re not just reducing your electricity bills but also contributing to a more sustainable production process. As the industry moves towards greener practices, manufacturers are increasingly looking for ways to minimize their environmental impact. Choosing an energy-efficient machine can significantly reduce your carbon footprint, which is an essential consideration for businesses today.

Why Grand Star‘s Tricot Machines Are the Best Choice

At Grand Star, we understand the importance of reliability, precision, and flexibility in fabric manufacturing. Our Tricot Machines for Sale are built with advanced technology to cater to the diverse needs of various industries. Here’s why our machines stand out from the competition:

- Advanced Human-Machine Interface (HMI)

Our tricot machines come equipped with an intuitive GrandStar® COMMAND SYSTEM, which provides an easy-to-use interface for controlling machine settings. This system simplifies the process of adjusting machine configurations, allowing for smoother operation and improved efficiency in production.

- Comprehensive Support and Training

We don’t just sell machines; we offer full support to ensure your team is fully trained and confident in operating the machine. Our global network of support teams provides installation, training, and after-sales services in countries such as Turkey, India, Vietnam, Indonesia, and the USA. For regions without local teams, we offer real-time online support and dispatch engineers as needed to ensure your machine is operating at full capacity.

- Industry-Leading Energy Efficiency

Our tricot machines are equipped with cutting-edge energy-saving features that not only lower operational costs but also help manufacturers stay competitive in an increasingly eco-conscious market.

Ready to Take Your Fabric Production to the Next Level?

Investing in a Tricot Machine for Sale is a game-changer for your production line. Whether you’re looking to produce high-performance automotive textiles, breathable sportswear, or luxurious upholstery fabrics, Grand Star’s tricot machines are engineered to deliver the highest standards of precision and efficiency. With the versatility, energy efficiency, and quality control systems in place, our machines are the ideal choice for manufacturers looking to improve their productivity and reduce costs. Don’t miss the opportunity to enhance your fabric production. Contact us today to learn more about how our tricot machines can support your business, or schedule a demo to see the power of precision manufacturing for yourself!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.