Can Industrial Tricot Machines Reduce Yarn Waste?

Industrial Tricot Machines are no longer just about speed and patterns; they are becoming a powerful tool to cut yarn waste and protect your margins. As Grand Star Technology, we have talked to the mills. Most of them face the same problem: yarn costs keep rising, but fabric prices do not. Every broken end, every roll of off-quality fabric, is money lost. The question we hear most often is very simple:

❓Can Industrial Tricot Machines Really Reduce Yarn Waste?

❓Our answer is: yes – if the machine is designed for control, stability, and visibility.

What Yarn Waste Means for Modern Knitters

In warp knitting and weft-insertion applications, waste rarely comes from one big mistake. It comes from many small issues that repeat all day long.

- Frequent machine stops that leave unusable fabric at the beginning and end of each run

- Unstable yarn tension that causes defects and rejected rolls

- Poor monitoring, so faults are found late, after many meters of fabric

- Long setup times when switching styles, leading to extra trial fabric

For many factories, this adds up to thousands of meters of scrap fabric per year. Even a small improvement in first-quality rate can make a big financial difference.

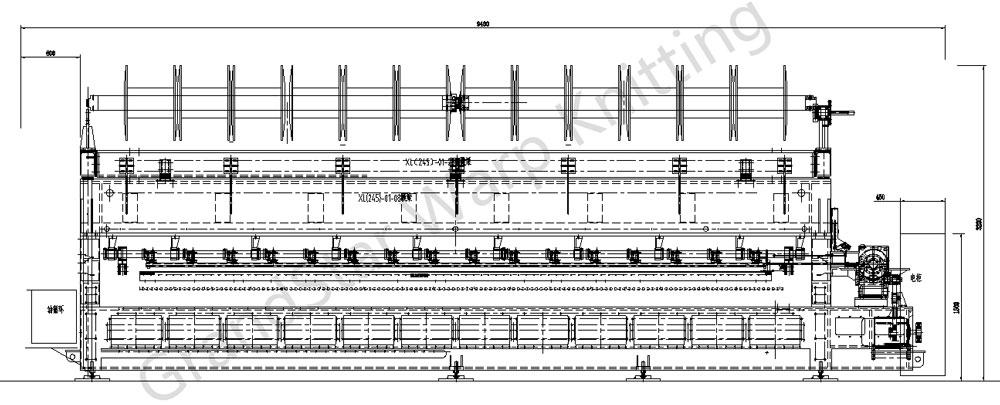

That is why we developed our tricot machine with weft insertion to focus on three things: precise yarn guidance, stable tension, and intelligent monitoring. Together, these features help Industrial Tricot Machines turn more yarn into sellable fabric.

How Industrial Tricot Machines Cut Yarn Waste

- Precision Knitting, Less Scrap

Yarn waste often starts at the stitch. If loops are not formed cleanly, problems show up later as defects, repairs, or rejected rolls.

Our Industrial Tricot Machines use:

- An individual needle bar with compound needles for precise, repeatable knitting

- A slider bar with plate slider units (½”) to support accurate loop formation

- A sinker bar with compound sinker units to keep the fabric stable during knitting

These elements work together to keep the structure clean and consistent. Fewer loops are missed. Fewer stripes or holes appear. That means less fabric you have to cut away or sell at a discount.

The guide bars also play a key role. At Grand Star Technology, we use guide units made from carbon-fiber-reinforced materials. They are light and durable. This helps reduce machine vibration and wear, which can cause small but costly quality issues over time.

- Smart Control for Stable Tension

Uneven tension is one of the biggest hidden sources of yarn waste. When tension changes, pattern, density, and handle all change. Sometimes the fabric looks fine on the machine, but problems appear in finishing or cutting.

Our Industrial Tricot Machines address this with:

- Electronically controlled yarn let-off at each warp beam position for stable, uniform feed

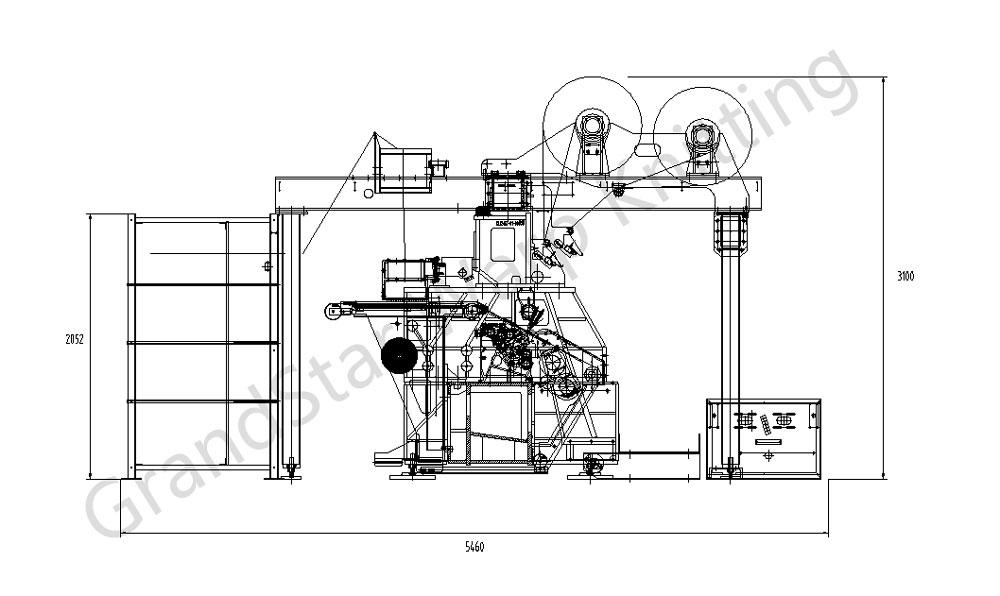

- A weft-insertion system with a yarn-laying carriage handling 24 ends for controlled placement

- An electronically regulated fabric take-up system driven by a geared motor and four rollers

When yarn feed and take-up move in harmony, tension remains stable. This reduces faults, reduces rework, and helps you get more first-quality fabric from every kilogram of yarn.

Different warp beam configurations (for example, 2/3 x 812 mm or 2/3 x 1016 mm) give you flexibility in production planning. You can choose setups that match your main styles and minimize changeover waste.

- Monitoring Problems Before Yarn Is Lost

Finding problems early is one of the easiest ways to reduce yarn waste. That is why our Industrial Tricot Machines integrate smart monitoring systems:

- Laserstop for accurate and immediate fault detection

- An integrated camera to help operators monitor fabric quality in real time

If something goes wrong, the machine can stop quickly. The operator sees the issue and takes action. You lose a few meters, not a full batch.

All this is controlled through the GrandStar® Command System. With a clear, user-friendly interface, operators can configure, control, and adjust all electronic functions easily. This reduces setup errors and shortens the “trial and error” phase when starting a new style – another hidden source of yarn waste.

Can Industrial Tricot Machines Create More Value?

Reducing yarn waste is important. But the real goal is higher value from the same machine time and material.

- From High Fashion to Automotive

Our Industrial Tricot Machines with weft insertion are used in many applications:

- High-fashion fabrics- delicate, intricate structures where scrap is expensive

- Sportswear and performance textiles- stretchable, breathable fabrics that demand consistency

- Technical textiles- industrial fabrics and filtration materials where defects are not allowed

- Home furnishings and automotive interiors- large yardage orders where every small saving adds up

In these markets, buyers expect stable quality and reliable delivery. By reducing waste and rework, you can protect your lead times and improve your reputation.

The optional EL-Drive pattern system, with three electronically controlled motors and shog distances up to 50 mm (or even 80 mm), also helps reduce style-change waste. Complex patterns can be set electronically instead of through heavy mechanical changes. That means faster switches, fewer trials, and less yarn used for testing.

- Partner with Grand Star Technology

A machine alone cannot reduce yarn waste. People and processes matter just as much. That is why we focus on training and service as part of our solution.

We provide:

- On-site installation and tailored training

- Online guidance and video tutorials to support your team

- Local after-sales teams in key regions such as Turkey, India, Vietnam, Indonesia, and the USA

- Regular engineer visits every 1–2 months in many markets to keep machines running at their best

When operators understand how to use Industrial Tricot Machines correctly, they make fewer mistakes. When maintenance is regular, machine stops become shorter and less frequent. Both factors help to lower yarn waste.

Our electrical system, with a speed-regulated drive and a connected load of 25 kVA at 380V three-phase power, is designed for stable, efficient operation. An oil/water heat exchanger helps keep temperature under control and supports machine longevity. The result is consistent performance, day after day.

Can Industrial Tricot Machines Reduce Yarn Waste?

With the right design, control, and support, we believe the answer is yes.

If you want to explore how Grand Star Technology can help your factory cut yarn waste and upgrade fabric quality, reach out to our team today.

Let’s look at your current styles, challenges, and goals – and see how our Industrial Tricot Machines with weft insertion can turn more of your yarn into profit.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.