How Warp Knitting For Fabrics Powers Triple Jacquard Design

How Warp Knitting for Fabrics powers triple jacquard design is becoming a hot topic in mills that want both speed and style. Triple Jacquard Double Raschel 7/3 is a specialized warp knitting setup that combines a double needle bar raschel machine with three jacquard guide bar groups. This structure lets you build thick, stable fabrics with rich, layered patterns in one continuous process. But why are more factories shifting to this technology now, and what hidden advantages does it bring to real production lines? Let’s look deeper in the following sections.

Turning Jacquard Complexity into Stable Fabric Production

If you work with triple jacquard today, you probably know the trade-offs too well. Beautiful patterns usually mean more setup time, more waste, and more pressure on your technicians. Fast output often means simplified designs and a constant fight to keep quality stable. Add shorter order cycles and rising labor costs, and every new style can feel like a risk.

At Grand Star Technology, we look at this challenge from the knitting floor upward. Warp Knitting for Fabrics gives mills another way forward. Because many yarns are fed in parallel and looped on two needle bars, warp machines naturally build dense, stable structures at industrial speed. When we layer jacquard control on top, those structures turn into detailed patterns that still run efficiently.

Instead of choosing between creativity and productivity, our goal is to help you do both. We design our triple jacquard double raschel solution so that:

- Patterns stay clear and repeatable

- Machine settings are easy to control and save

- Style changes do not bring production to a halt

In other words, Warp Knitting for Fabrics becomes a tool for reliable innovation, not just another complex machine on the floor.

Inside Our Triple Jacquard Warp Knitting Solution

Our triple jacquard double raschel machine is built to take a digital design file and translate it into physical fabric with fewer experiments and corrections. A working width of about 3454 mm (136″) gives room for wide-width fabric, multiple garment panels, or mirrored pattern layouts in a single run. This helps improve fabric yield and makes the cutting room more efficient.

A flexible gauge range from E18 to E28 means one machine can handle heavier structures for technical uses as well as finer fabrics for apparel and home textiles. This is especially useful for mills that need to serve different markets with the same equipment base.

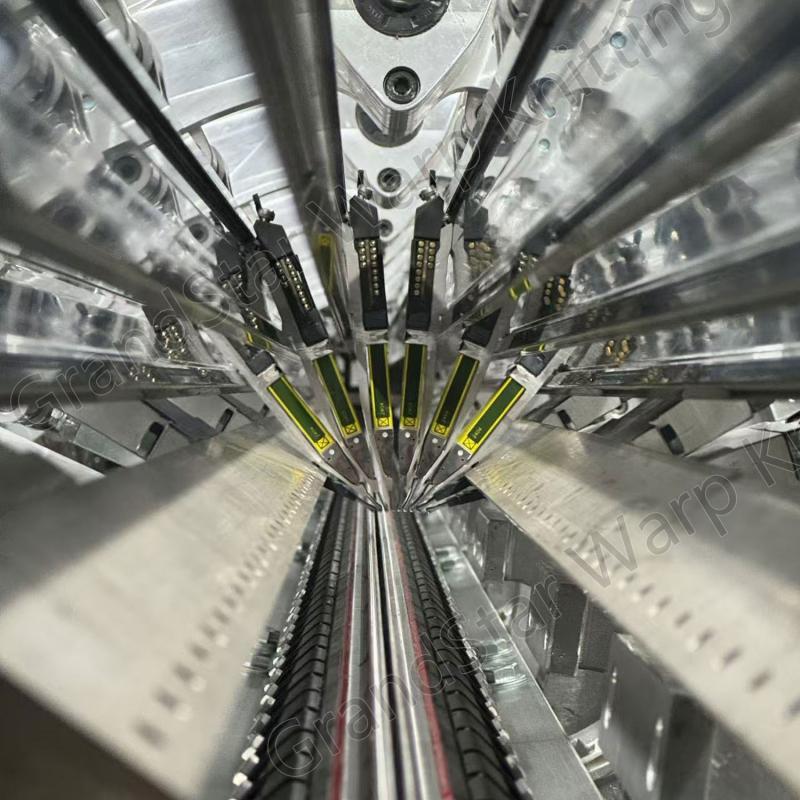

Several knitting elements work together to support triple jacquard designs:

- Four ground guide bars build the basic fabric structure and stability

- Three groups of piezo jacquard guide bars control patterning and fine details

- Two individual latch needle bars, plus two knock-over comb bars and two stitch comb bars, help produce clean stitches on both beds

This layout supports sharp pattern edges, balanced surfaces, and reduced defects such as broken yarns or distorted motifs.

For process control, the knock-over comb bar distance can be adjusted continuously from 2 to 12 mm. This lets your team fine-tune thickness, loop shape, and hand feel when switching from, for example, automotive upholstery to lighter fashion or home fabrics. Instead of rebuilding settings from zero, technicians can refine and repeat known “recipes”.

The machine is driven by our GrandStar® Command System, an operator-friendly interface that centralizes electronic control. Your staff can:

✅ Set and adjust speeds, tensions, and pattern movements on-screen

✅ Store and recall style parameters for repeat orders

✅ Monitor key status points without constantly stopping the machine

Warp Knitting for Fabrics also benefits from electronically controlled yarn let-off for each fully mounted warp beam position. This helps keep yarn tension stable even when working with sensitive yarns or higher operating speeds. An electronically regulated fabric take-up with multiple rollers supports consistent fabric density and reduces unwanted variation along the full length of the roll.

With a speed-regulated main drive and a total connected load of around 7.5 kW, the machine connects easily to standard 380 V ±10% three-phase plant power. That makes integration straightforward for most knitting facilities, without special electrical infrastructure.

To protect your investment, we also consider environmental factors. The equipment is designed to run best at about 25°C with controlled humidity. A circulating air heat exchanger and monitored oil filtration system help reduce wear and keep motion parts running smoothly. For plant managers, this means fewer surprises, more predictable maintenance windows, and better long-term stability from the line.

From Application Ideas to Long-Term Partnership

Warp Knitting for Fabrics used in triple jacquard construction opens doors well beyond a single niche product. Our customers use these fabrics in several key areas:

✅Fashion & Apparel – Outerwear, activewear, and accessories that need pattern-rich surfaces with strong abrasion resistance and dimensional stability.

✅ Home Textiles – Upholstery, curtains, and bedding where decorative design must stay sharp after long-term use.

✅ Technical Textiles – Automotive interiors, industrial fabrics, and protective layers that require robust, engineered structures.

✅ Luxury And Special Occasions – Bridal, couture, and event fabrics where unique jacquard textures become part of the brand identity.

But a machine alone is not enough. Many mills hesitate to invest because they worry about training, changeover know-how, or how quickly help will arrive if something goes wrong. We understand these concerns, and we build our service model around them.

Grand Star Technology supports Warp Knitting for Fabrics with a complete installation and training program. Your team can learn through manuals, online sessions, video guidance, and on-site training tailored to your product mix. Our support goes beyond theory. We guide your staff through new style setup, trouble prevention, and fine adjustment for many yarn types and fabric designs. These machines are already working in over 20 countries, with dedicated local teams in Turkey, India, Vietnam, Indonesia, and the USA. In these regions, we do not wait for problems to appear. Our engineers visit customers on a regular schedule, typically every one to two months, to:

- Inspect machine performance

- Review maintenance routines

- Discuss new styles and product ideas

Where we do not yet have a local team, we start with real-time online support and, when necessary, send engineers from the nearest hub. The aim is always the same: minimize downtime and give your operators confidence that expert help is available.

For mill owners, technical directors, and production managers, the overall value is clear:

- Your triple jacquard capacity is supported by an experienced, global team

- Your operators are not left alone to manage complex electronic settings

- Your capital investment is backed by ongoing service and application support

If you are exploring new jacquard developments or thinking about upgrading existing raschel lines, this is a good moment to reconsider what Warp Knitting for Fabrics can do for your business. With the right machine and the right partner, triple jacquard does not have to be a high-risk specialty. It can become a stable, high-margin part of your core product portfolio.

Call to Action

Want to find out how our triple jacquard warp knitting solution could fit into your production plan? Get in touch with Grand Star Technology to share your fabric targets, request a tailored technical proposal, or arrange a live machine demonstration. Let’s turn your next jacquard program into a reliable, scalable success on your knitting floor.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.