Direct warper for filament yarn

| Direct Warper for filament yarn – Warping Machine / Warp Preparation | |

| Model No. | GS-DS 21-30 / 21/40 DNC |

| Application | Filament Yarn |

| Beam Size | Max 50*40″ |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

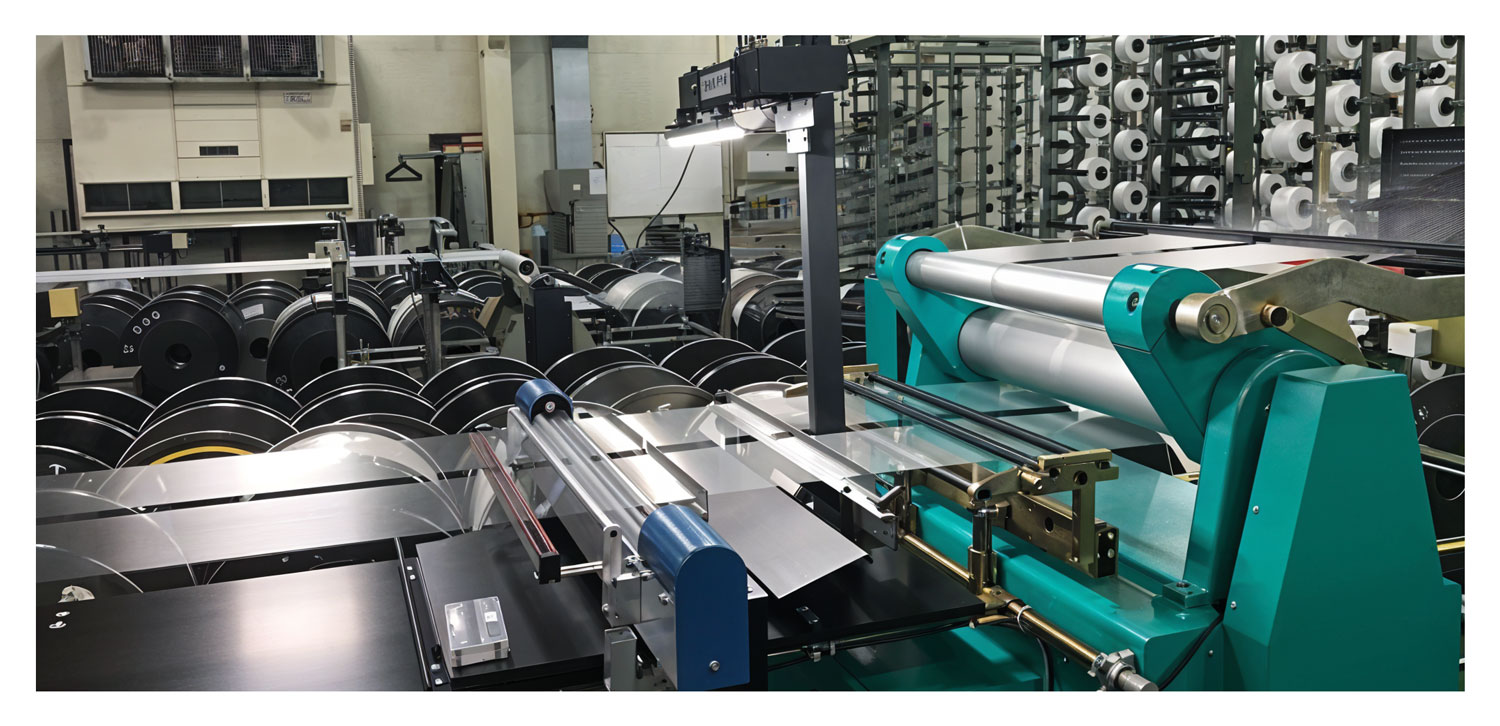

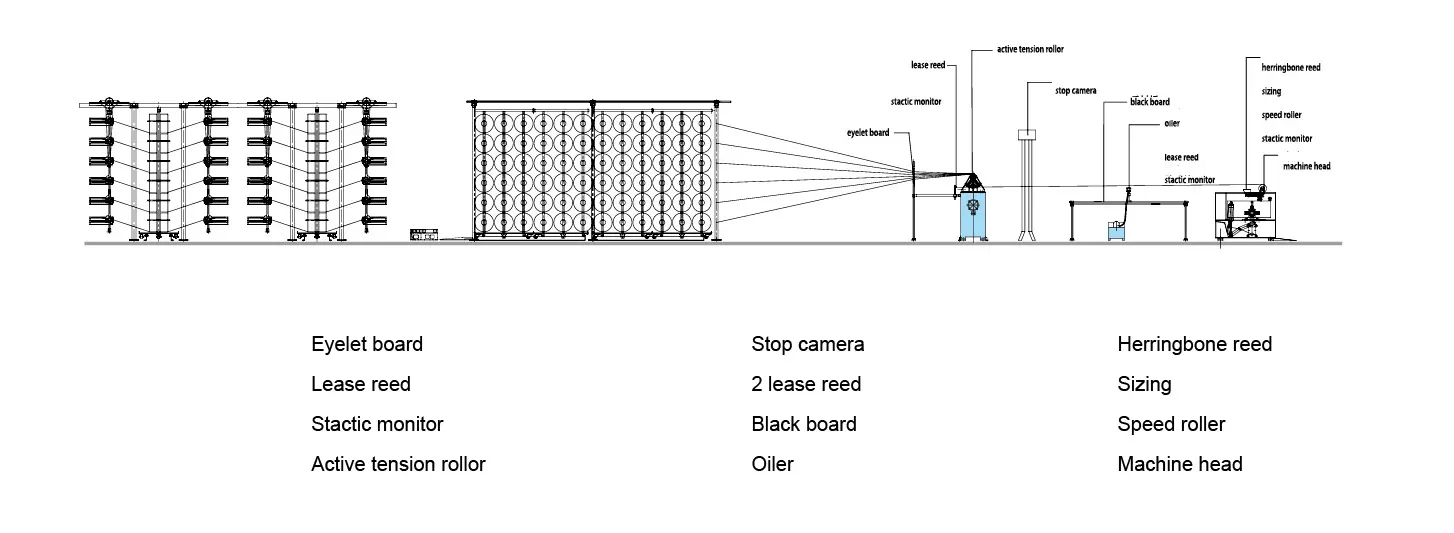

Achieve Higher Efficiency and Superior Warp Quality with Our Advanced Warping Technology

Our cutting-edge warping solutions are designed to deliver exceptional performance, precision, and ease of operation. With state-of-the-art automation and intelligent control systems, our machines provide industry-leading efficiency and reliability. Maximize productivity, enhance beam quality, and optimize the warping process with our innovative features.

Your Benefits

- Unparalleled Productivity: Experience warping speeds of up to 1000 m/min, significantly boosting production efficiency.

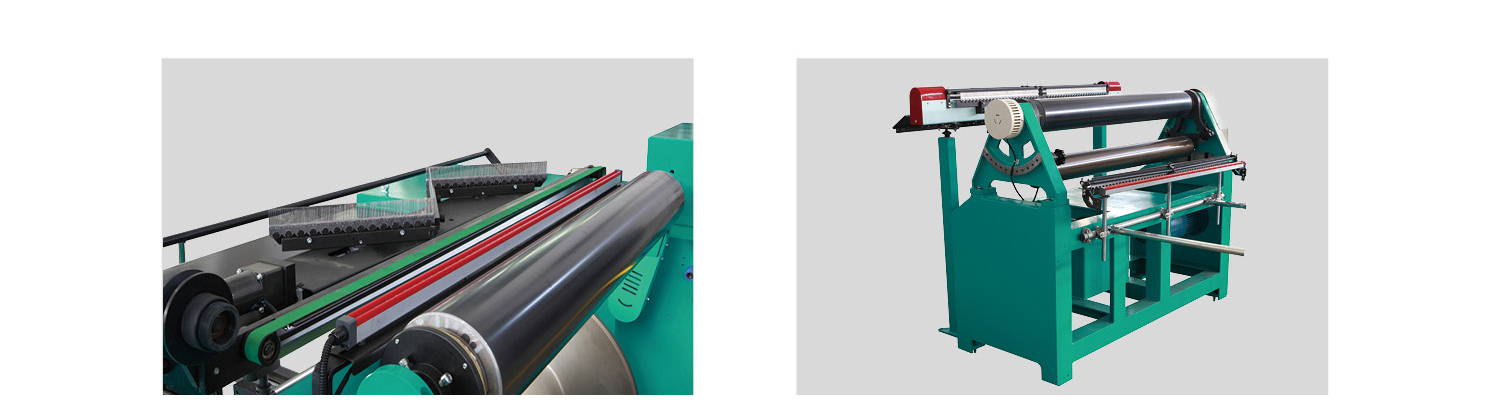

- Enhanced Warp Length & Hardness: Optional pressure roller device ensures greater warp length and superior beam hardness.

- Intelligent Yarn Storage System: Integrated 9 m back-winding capacity for precise control of the last 9 meters of the warp sheet.

- Exceptional Beam Quality: Advanced beam circumference control ensures consistent and optimal beam formation.

- Highly Intelligent Brake Synchronization: Guarantees exact stop locations for improved operational precision.

- Automatic Yarn Tension Regulation: Maintains uniform tension, ensuring stable warping results.

- Comprehensive Quality Control: Integrated protocol management and beam data saving enhance traceability and production accuracy.

- Optimized Ergonomic Design: Engineered for ease of use, providing a comfortable and efficient working environment.

Product Features

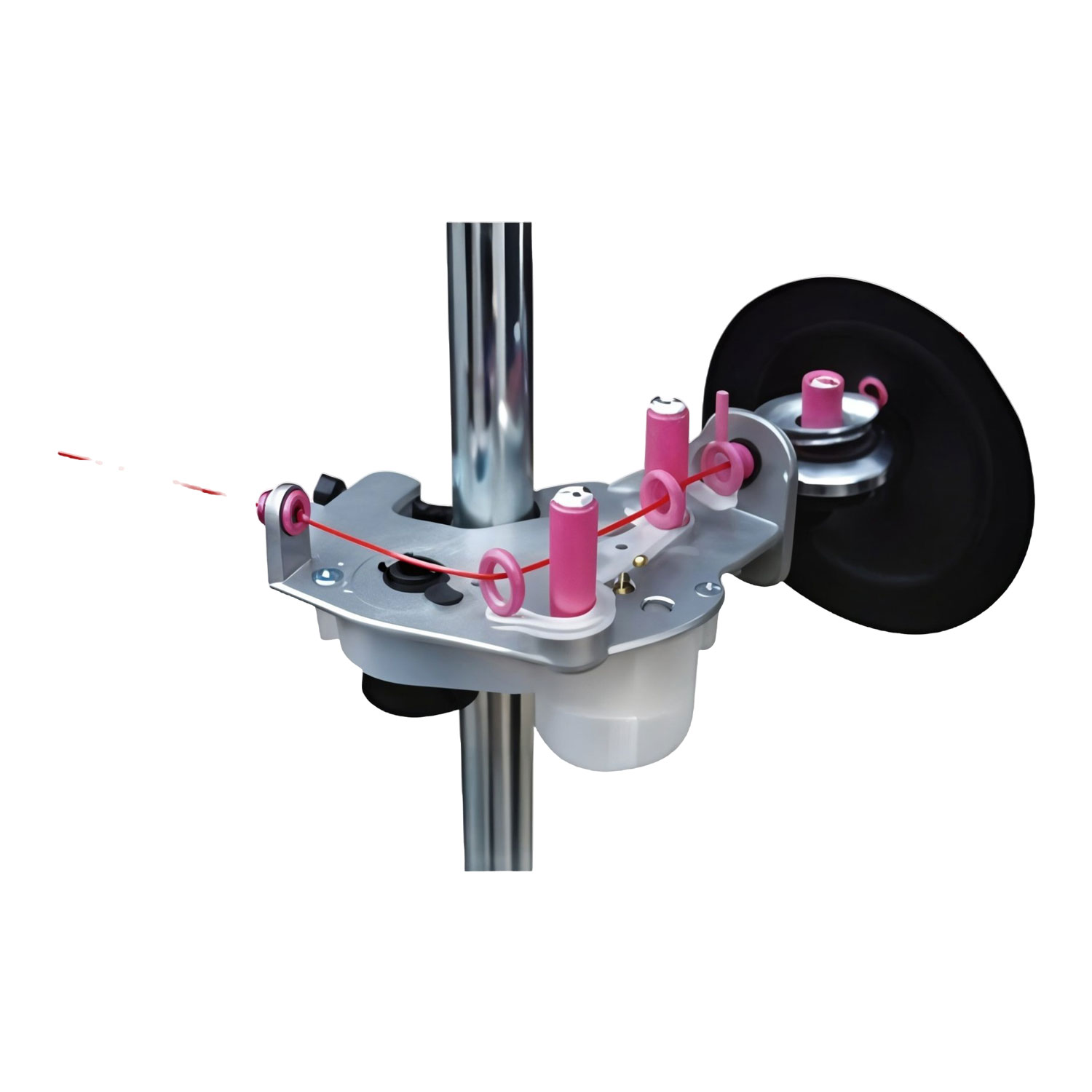

- Advanced Levelling Roller Unit: Enables infinitely adjustable wrapping angle for precise warp sheet handling.

- Superior Lubrication System: Features infinitely variable oil coating for optimal yarn processing.

- Flexible Front Reed Movement: Allows both vertical and horizontal traverse to accommodate diverse warping requirements.

- Intuitive Touchscreen Interface: User-friendly operation with a modern touchscreen control panel for seamless adjustments.

- Intelligent Yarn Breakage Detection: Camscan end break detection system with camera technology provides real-time monitoring and accurate display of broken ends.

- High-Tenacity Device Compatibility: Designed to support specialized applications requiring high-tenacity yarns.

Elevate Your Warping Efficiency Today

Discover the next level of precision and performance with our advanced warping technology. Engineered for excellence, our machines empower you to achieve higher production efficiency, superior beam quality, and effortless operation. Contact us today to explore how our solutions can optimize your textile production process.

Training & Service

Installation & Training

Our technical support covers warp knitting machine training via manuals, videos, online resources, and on-site programs in over 20 countries, with teams in five key regions.

Local Service

Grandstar ensures machine longevity with on-site services across Turkey, India, Vietnam, Indonesia, and the USA, combined with professional maintenance routines.

Application

- Filament Yarn Processing:

This machine is perfect for direct warping of filament yarns, including synthetic, polyester, and nylon yarns, ensuring precise tension and consistent quality. - High-Tenacity Yarn Warping:

With its high-tenacity device, it can handle yarns with up to 1600N tension, making it suitable for heavy-duty textile applications such as industrial fabrics and technical textiles. - Textile Weaving Preparation:

It prepares warp beams efficiently for weaving operations, offering uniform tension and alignment critical for high-quality fabric production. - Specialty Fabrics Production:

The tandem warping device allows for processing specialty yarns, enabling the production of customized fabrics for industries such as automotive, aerospace, and home furnishings.

GS-DS Series Technical Specifications

| Feature | GS-DS 21/30 DNC | GS-DS 21/40 DNC |

|---|---|---|

| Maximum Speed | 1000 m/min. | 1000 m/min. |

| Maximum Yarn Tension | 200N | 200N |

| Pressure Roller | Available | Available |

| Levelling Roller Unit | Yes | Yes |

| Tandem Warping Device | Available | Available |

| High-Tenacity Device | Available | Available |

| Maximum Yarn Tension (High-Tenacity) | 1600N | 1600N |

| Maximum Speed (High-Tenacity) | 600 m/min. | 600 m/min. |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |