Geo Textile Machine Paves the Way for Smarter Construction

In recent years, smart construction has become a global trend. According to a report by MarketsandMarkets, the geotextile market is expected to reach $11.3 billion by 2027. Behind this growth is a quiet but powerful tool: the Geo Textile Machine.

This machine plays a key role in producing strong, flexible, and eco-friendly fabrics. These fabrics are used in roadbeds, tunnels, dams, and landfills. They help prevent soil erosion, improve drainage, and extend the life of infrastructure.

Many construction companies now rely on this advanced knitting technology. It not only speeds up production but also ensures consistent quality. As cities grow and climate risks increase, the demand for smarter, more sustainable materials rises.

The Geo Textile Machine is no longer just a part of textile tech – it’s shaping the future of modern infrastructure.

Smarter Construction Needs Smarter Tools

Global Rise of Smart Infrastructure and Geotextile Demand

Cities around the world face growing stress on roads and bridges. Planners need new materials that last longer and cost less. This surge drives demand for geotextile products. A modern Geo textile machine answers this call with higher output and precision.

Role of Advanced Textiles in Erosion Control, Drainage, and Road Stability

Soil erosion threatens slopes and embankments. Advanced textiles help keep soil in place. They also improve water flow under pavements. Roads become safer when drainage works as designed. These benefits make geotextile fabrics indispensable in many projects.

Geo Textile Machines as a Driver of Construction Innovation

New knitting machines bring speed and consistency. They deliver strong, customizable fabrics for any terrain. Manufacturers can adjust strength, weight, and permeability with ease. Thus, Geo textile machines are at the heart of modern infrastructure solutions.

Market Growth and Innovation Trends

Industry Forecast: Geotextile Market to Hit $11.3 Billion by 2027

Analysts project steady growth in the geotextile sector. By 2027, the market should exceed $11 billion. Rising urbanization and climate risks fuel this expansion. Companies invest in new equipment to capture these gains.

Shift from Manual to Precision Textile Engineering

Old machines required skilled operators and manual tweaks. Today’s systems use exact controls and sensors. This shift boosts consistency and cuts waste. A single Geo textile machine can replace several older units.

Sustainability and Efficiency Driving New Technology Adoption

Governments push for green construction rules. Producers respond with low-energy designs and recycled yarn options. Automated machines trim excess material and save power. In the long run, they cut costs and carbon footprints.

From Basic to Advanced – The Evolution of Knitting Machines

Traditional vs. Modern Warp Knitting Technologies

Warp knitting began with simple looms and basic patterns. Early machines had fixed settings and slow speeds. Modern warp knitting offers flexible gauge choices and wide working widths. These upgrades meet varied project needs.

Rise of Automated Control Systems and Material Efficiency

Digital controls now adjust settings on the fly. Operators use touchscreens to monitor machine health. Yarn tension and fabric take-up auto-regulate for uniform quality. Automated yarn let-off and roll batching save labor hours.

Introduction to Double Needle Bar Raschel Machines as Next-Gen Solutions

The Double Needle Bar Raschel stands out for net and mesh production. It uses two needle bars and extra comb bars. Users can choose gauges from E2 to E18. Working widths range from 130″ to 256″. This Geo textile machine excels in strength and speed. It fits well into any smart construction line.

Introducing the Double Needle Bar Raschel for Net

Designed for Precision Geotextile Net Production

The machine targets high-grade nets. Each stitch is even. Strength stays constant across the roll. Your Geo textile machine output meets tight job specs.

Ideal for Heavy-Duty Applications

Road embankments need stable nets. Drain beds need clean water paths. Filters need fine yet tough mesh. This model covers all three tasks with one setup.

Built to Handle Complex Textile Structures with Consistency

Two needle bars work in perfect sync. Extra comb bars guide every thread. Tension sensors keep errors away. You get repeatable quality on every shift.

Technical Specifications at a Glance

Working Width & Gauge

Choose 130″, 180″, 210″, or 256″ widths. Select gauges from E2 to E18. The Geo textile machine adapts to thin mesh or thick web.

Knitting Elements

Dual needle bars boost output. Up to nine ground bars shape complex patterns. Knock-over combs secure loops and raise fabric strength.

Warp Beam Support

Free-standing frames hold up to nine beams. Each beam measures 812 mm. Quick swaps keep downtime low and orders moving.

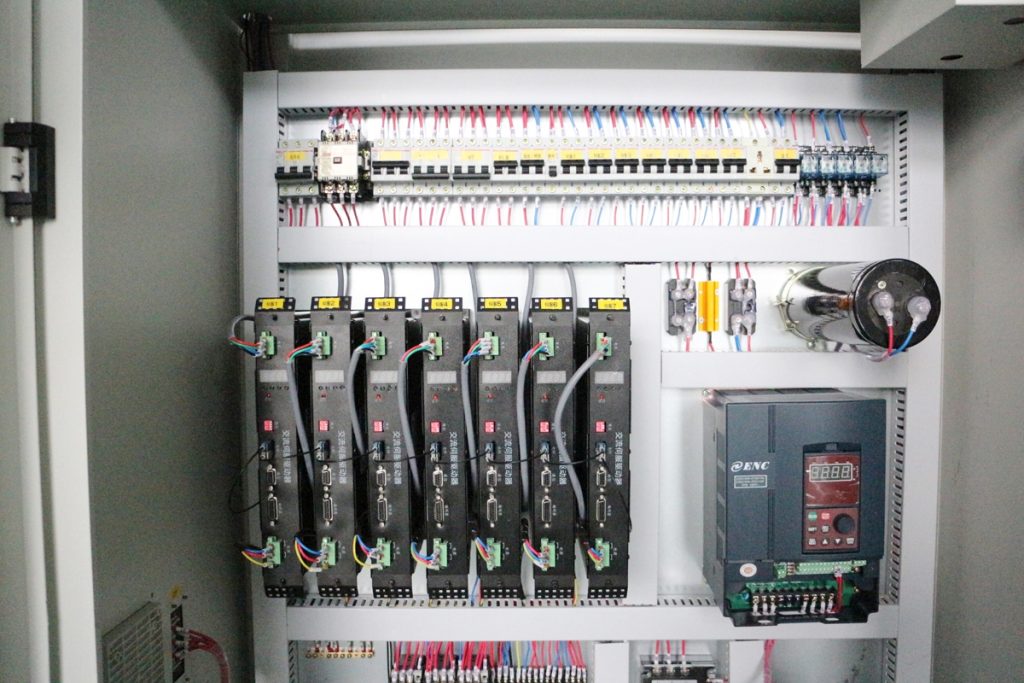

Advanced Control and Motion Systems

GrandStar® Command System: Intuitive Interface for Precision Control

The touch screen shows live data. Operators set speed, gauge, and pattern with a few taps. No deep code needed.

Yarn Let-Off Device: Independent Electronic Control per Warp Beam

Each beam feeds yarn at its own rate. Sensors stop slack and over-pull. Fabric weight stays uniform from start to end.

Take-Up System: Electronically Driven Four-Roller Unit

A geared motor drives four rollers. The pull is smooth and steady. Finished nets wind tight without creases – a key gain for any Geo textile machine line.

Engineering Power and Environmental Readiness

Electrical Equipment: 7.5 KW Power, Voltage Flexibility, Safe Cabling Specs

The main motor is speed-regulated. The system runs on 380 V three-phase. Heavy-duty cables guard against heat and surge.

Oil & Cooling: Circulating Air Heat Exchanger, Dirt-Monitoring Filters

Oil flows through a sealed loop. Air fans cool key parts fast. Filters watch for dirt and signal service time.

Working Conditions: Stable under 25 ℃ ± 3 ℃, 65 % ± 10 % Humidity

The frame resists floor pressure up to 4000 kg/㎡. Electronic boards stay calm in warm plants. Your Geo textile machine runs day and night without drift.

Support, Service, and Global Reach

Installation & Training

Setup guides come in clear steps. Online calls solve quick doubts. On-site teams fine-tune tension and pattern files.

Local Service

Spare parts ship from nearby hubs. Engineers reach most sites within hours. Routine care keeps the Geo textile machine at peak output.

About Grand Star Technology

Founded in 2012, the firm focuses on warp knitting. ISO 9001 methods guide every build. Customer feedback drives new upgrades and smart add-ons.

Elevate Your Projects with Cutting-Edge Geo Textile Machines!

Ready to take your construction projects to the next level? The Double Needle Bar Raschel for Net is the ideal solution for precise, durable, and efficient geotextile production. Don’t let outdated machinery hold you back – embrace innovation and experience unmatched quality and speed. Contact us today to learn more and transform your operations with the latest in textile technology!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.