How Does the Geogrid Warp Knitting Machine Make Roads More Durable?

In recent years, road durability has become a growing concern worldwide. Cracks, sinking, and early damage are common issues. A new technology is helping to solve these problems: the Geogrid Warp Knitting Machine.

According to a 2024 industry report, geogrid-reinforced roads last 30-50% longer than traditional ones. These machines use high-strength fibers to produce geogrids, which are then laid under roads and pavements. The result? Stronger support, better load distribution, and improved resistance to wear.

Many infrastructure projects in Asia and Europe are now adopting this technology. Experts say it’s not only cost-effective, but also eco-friendly. As global demand for smarter, longer-lasting roads increases, the geogrid warp knitting machine is quickly becoming a key player in the field.

The Infrastructure Challenge

The Rising Demand for Road Durability

Roads around the world face more traffic than ever. Heavy trucks, extreme weather, and long-term wear all damage road surfaces. Governments and builders need roads that last longer and cost less to maintain. Stronger materials and smarter construction methods are now in high demand.

Why Traditional Materials Fall Short

Traditional roadbeds often use gravel and sand layers. These materials shift and break down over time. They cannot hold up under heavy loads or constant pressure. Repairs are frequent and costly. The result is wasted time, money, and resources. A better solution is needed.

Engineering Solutions with Warp Knitting Technology

This is where warp knitting comes in. A Geogrid warp knitting machine produces high-strength geogrids used in road construction. These geogrids stabilize the soil and distribute weight more evenly. Roads reinforced with geogrids are stronger and last longer. The technology offers a practical, long-term answer to infrastructure challenges.

The Power of Geogrid Warp Knitting Machines

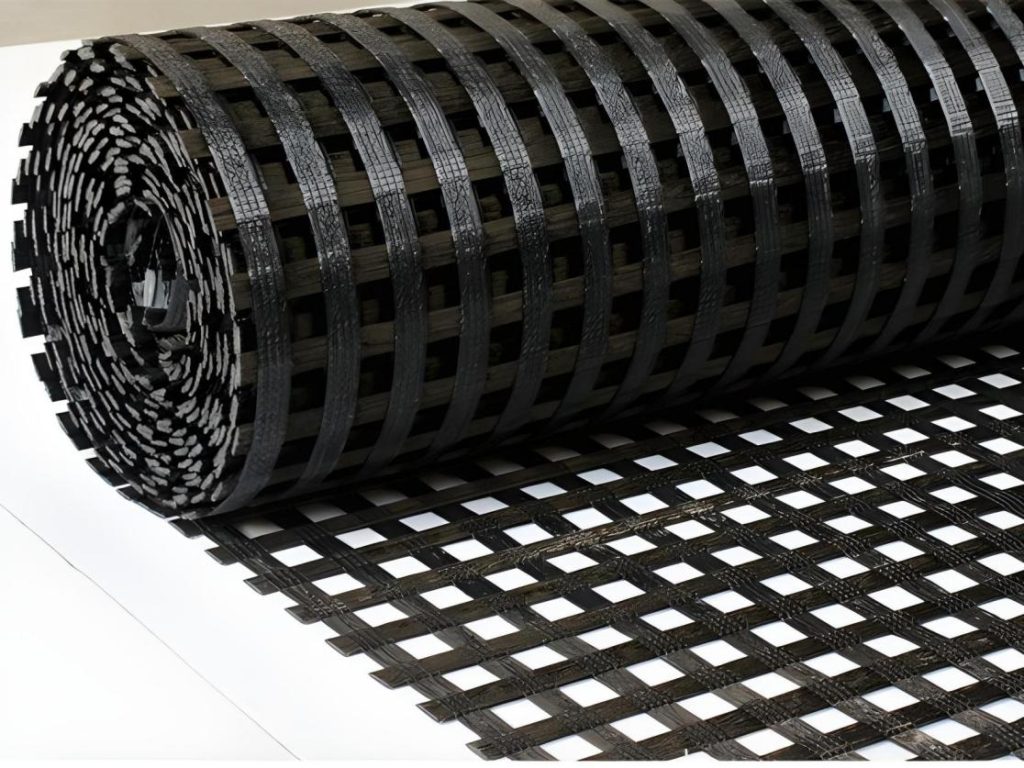

What Is a Geogrid?

A geogrid is a mesh-like structure made from high-strength yarns. These grids are laid under roads, embankments, or railways. They support the ground and help prevent movement. Geogrids are often made using a Geogrid warp knitting machine, which ensures precision and durability in every piece.

Key Benefits for Road Construction

Geogrids improve road strength and extend their life by reducing cracks and deformation. They also lower repair costs over time. A Geogrid warp knitting machine creates consistent and reliable net structures. This consistency leads to safer, more durable roads across a variety of conditions.

Global Case Studies & Market Growth

Countries like Germany, China, and India are now using geogrid technology widely. In recent studies, roads with geogrid reinforcement showed 30%-50% longer lifespans. As demand grows, the Geogrid warp knitting machine market continues to expand, especially in developing regions investing in long-term infrastructure.

From Yarn to Reinforcement – Inside the Technology

How Warp Knitting Works

Warp knitting is a technique that weaves yarns into a strong, open mesh. The yarns run vertically in parallel rows. The machine links these yarns in precise patterns to form the geogrid. The Geogrid warp knitting machine ensures each unit is identical, strong, and reliable.

Precision Engineering Behind the Fabric

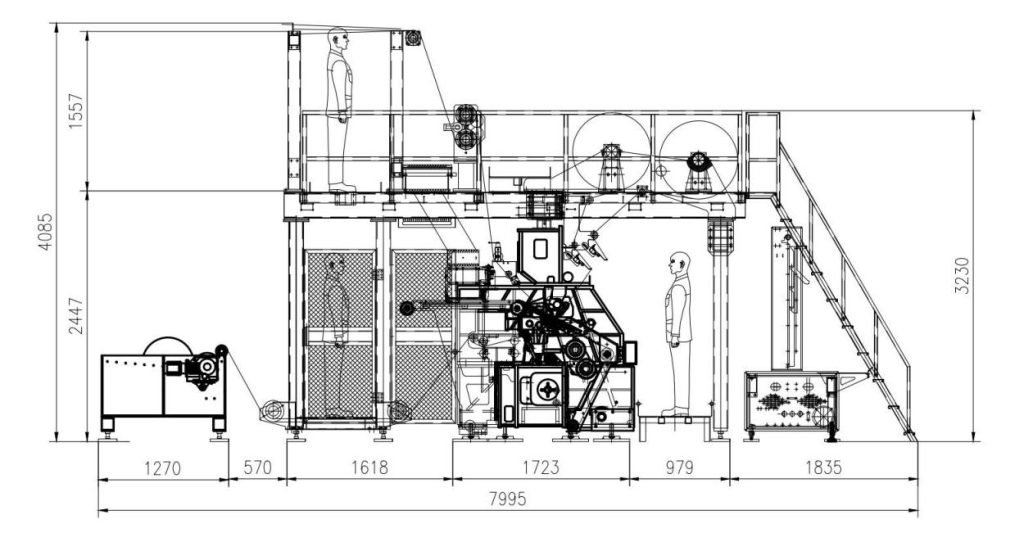

These machines use latch needles and advanced control systems. They operate at high speeds without sacrificing quality. The design allows for different gauges and widths, making it easy to customize for specific road projects. Every Geogrid warp knitting machine is built to meet the tough demands of modern construction.

Environmental and Economic Advantages

Geogrids reduce the need for thick gravel or concrete layers. This saves natural resources and lowers carbon emissions. They also cut long-term costs by extending road life. By using a Geogrid warp knitting machine, manufacturers can produce more sustainable and affordable solutions for the infrastructure industry.

A Technological Leap — Raschel Knitting Net Machine

Why This Machine Matters for Geogrid Production

The Raschel knitting net machine with latch needle is an important tool in modern geogrid production. It plays a major role in creating strong, flexible nets for construction. Many Geogrid warp knitting machine models use Raschel technology as their foundation. These machines are known for their stability, speed, and ability to handle high-strength yarns. They make production more reliable and efficient.

Latch Needle Design: Reliable & Versatile

Latch needles are the heart of the Raschel knitting net machine. They are strong, durable, and easy to maintain. The latch needle system works well under high loads, which is important for geogrid fabric. This design also offers versatility. Users can change needle blocks or install needles separately, depending on the fabric needs. In many Geogrid warp knitting machines, latch needles help produce nets with accurate spacing and consistent quality.

Ideal for Heavy-Duty Net Structures

Geogrids are used in roads, railways, and retaining walls. These applications require strong and stable netting. The Raschel knitting net machine is ideal for this job. It can handle tough yarns and produce wide, heavy-duty fabrics. This machine is often part of advanced Geogrid warp knitting machine setups used for heavy-duty construction needs.

Key Features of the Raschel Knitting Net Machine

Working Width & Gauge Flexibility

This machine supports a wide range of working widths. Options include 181″, 205″, 268″, and more, up to 503″. Users can choose the width that fits their production goals. The gauge options range from E3 to E18. This flexibility allows for custom mesh sizes. These features are essential for producing different types of geogrids using a Geogrid warp knitting machine.

Advanced Knitting Elements and Bar Configurations

The machine includes important knitting elements. These include the single-needle bar, knockover comb bar, slider bar, and stitch comb bar. The number of bars can be adjusted from 2 to 8. This allows for different knitting styles and fabric strengths. In many Geogrid warp knitting machine setups, these bars help form precise, durable mesh patterns.

Yarn Feeding: Multi-Beam, Electronically Controlled

The Raschel knitting net machine supports 2 to 8 warp beam positions. It is designed for free-standing sectional beams with a flange diameter of 812 mm. The yarn let-off device is electronic and uses a geared motor. Feeding devices include 3 or 4 positions with driven rollers. This system ensures stable yarn tension and smooth feeding. These features help the Geogrid warp knitting machine maintain steady production speed and product quality.

Intelligent Control and Fabric Handling Systems

User Interface & Motion Control System

The Raschel knitting net machine features a user-friendly interface. Operators can easily set machine parameters, adjust speed, and monitor production. The motion control system is powered by a servo motor. It ensures precise and consistent motion. This setup gives the Geogrid warp knitting machine reliable control over every knitting process.

Integrated Monitoring for Seamless Operation

The machine includes an integrated Laserstop system. This stops the machine if a yarn breaks or an error occurs. It reduces fabric waste and prevents damage. Monitoring systems keep production smooth and error-free. For any Geogrid warp knitting machine, real-time monitoring is key to achieving high-quality output.

Mechanical Fabric Take-Up & Batching Devices

The take-up system is mechanical, regulated by friction drive. It pulls the fabric evenly without tension damage. The batching device is separate and floor-standing. It rolls the cloth smoothly into large batches. These systems support stable, non-stop operation, making the Geogrid warp knitting machine efficient and productive.

Grand Star‘s Global Reach and Vision

Local Support Across Five Major Regions

Grand Star offers local support in key countries, including Turkey, India, Vietnam, Indonesia, and the USA. Local engineers provide installation help, regular maintenance, and quick service. This ensures that Geogrid warp knitting machine users receive timely assistance and minimize downtime.

Training, Installation, and Maintenance Services

Training is available in more than 20 countries. Grand Star offers manuals, videos, online help, and in-person training. Technicians guide clients through installation and machine setup. This makes it easier for users to operate the Geogrid warp knitting machine efficiently and safely.

Pioneering Warp Knitting Innovation from Fujian to the World

Founded in 2012, Grand Star is based in Fuzhou, Fujian. The company focuses on warp knitting machines and integrated control systems. The team continues to push innovation in the textile machinery field. Today, Grand Star machines, including Geogrid warp knitting machines, are used in construction, agriculture, and geotechnical projects around the world.

Build Stronger Roads with Smarter Technology

Ready to upgrade your production line with reliable, high-performance solutions? The Geogrid warp knitting machine – Raschel Knitting Net Machine Latch Needle offers the strength, precision, and efficiency your projects demand. Whether you’re reinforcing roads or scaling your textile operation, now is the time to act.

Contact Grand Star today for expert guidance, on-site support, and tailored warp knitting solutions built for the future.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.