How Glass Fiber Multi Axial Machine Boosts ROI

When it comes to composite textile manufacturing, margins matter. From energy costs to labor, every element of production affects your bottom line. Over the years, we’ve learned that the machines we choose have a direct impact not only on product quality but on long-term operational efficiency.

At Grand Star, we specialize in manufacturing advanced textile machinery, and one of our most impactful developments has been the Glass fiber Multi axial machine. This equipment has proven essential in helping factories reduce costs while maintaining output and quality. But how exactly does it save money? Based on our work with clients across aerospace, wind power, and marine industries, here’s what we’ve seen.

What is a Glass fiber Multi Axial Machine

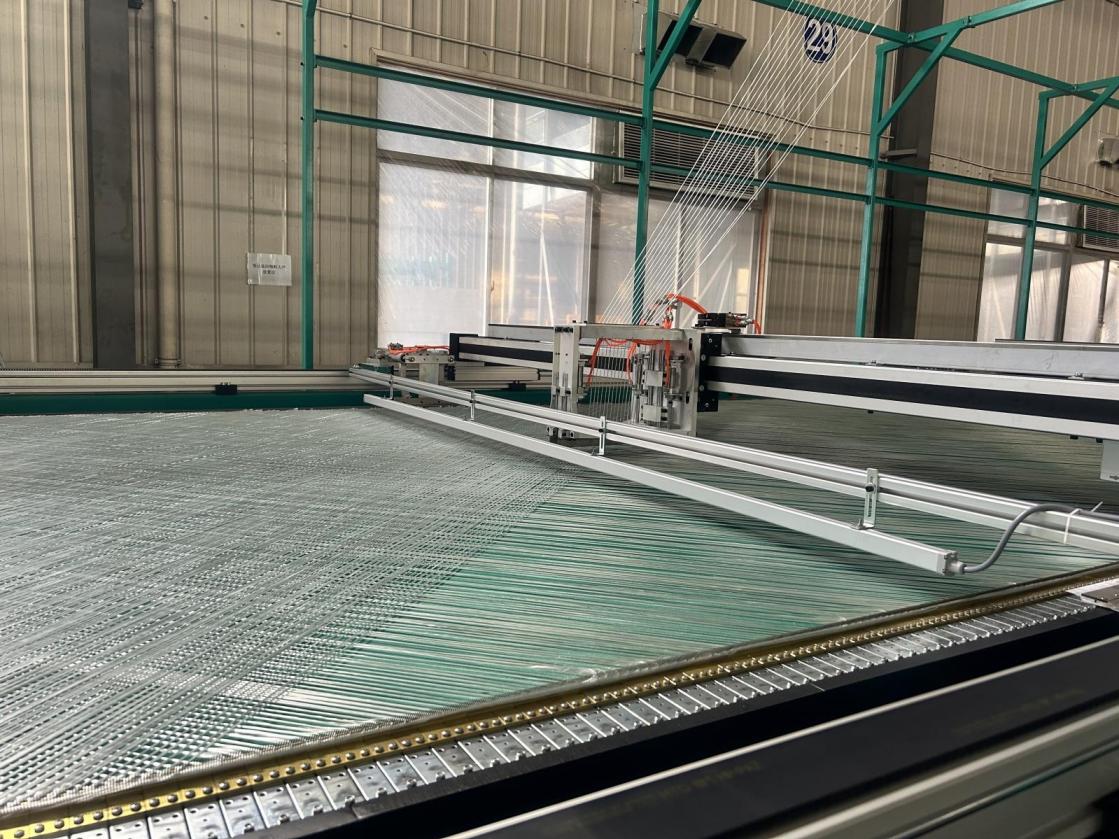

A Glass fiber Multi axial machine is a specialized textile machine used to produce multi-layer, multi-directional fiberglass fabrics, mainly for composite materials. These fabrics are widely used in industries such as wind energy, aerospace, automotive, and marine due to their high strength and lightweight properties.

The machine lays glass fiber yarns in various angles – typically 0⁰, 90⁰, ±45⁰ – to form a stable and customizable structure. It combines warp knitting technology with weft insertion and optional chopping functions, allowing precise control over fabric design, thickness, and strength.

Equipped with advanced features like servo-driven yarn let-off, electronic take-up, and touch-screen interfaces, the machine offers high-speed production, low material waste, and consistent quality. Its ability to automate complex layering patterns makes it an essential tool for manufacturers looking to improve efficiency and reduce costs in composite fabrication.

Automating for Efficiency

Before automation, composite textile production was heavy on manual work. Setting tension, aligning yarns, and cutting materials required trained staff to operate multiple machines. Mistakes were common – and costly. But things have changed.

The Glass fiber Multi axial machine takes over many of these tasks. It includes:

✅ A servo-controlled weft-insertion system, reducing misalignment and eliminating manual weft feeding.

✅ Electronically managed yarn let-off, where motors handle tension with precision. No more guesswork.

✅ A centralized touchscreen interface, allowing operators to control multiple parameters from one place.

One of our clients in the wind energy sector told us they used to assign two technicians per production line. After upgrading to our multi axial machine, they only needed one – and that person could manage two lines. That’s a 50% labor reduction right there. You also avoid costly shutdowns. With electronic yarn stop motion (optional), the system alerts you if something goes wrong before it turns into product waste.

Reducing Waste

You wouldn’t believe how much material gets wasted through manual errors – overfeeding yarn, poor tension control, off-spec batches. With this machine, waste becomes a rare exception, not a daily routine. Let’s take the chopper device for example. It uses servo-based controls to cut precisely according to the design pattern. That means no overshooting, no trimming losses, and no uneven fabric edges. Another often-overlooked cost saver is the fabric take-up system. It maintains consistent fabric tension throughout the roll, preventing slack zones or distorted sections. Every meter of fabric that comes off the machine meets quality expectations.

Even small improvements like these add up:

✅ Fewer defective rolls = less rework

✅ Better batch consistency = faster QA checks

✅ Reduced yarn waste = lower material costs

Across the board, these savings can amount to 15 – 30% fewer raw material losses, depending on production volume.

Scaling Smart

For manufacturers trying to grow, scaling up production can be tricky. Buy more machines? Hire more people? Expand your facility? All that costs money. But what if you could boost output without changing your footprint?

That’s exactly what the Glass fiber Multi axial machine allows.

Our models come in working widths from 2565mm (101″) to 4496mm (177″), giving you flexibility depending on the scale of your operations. For large-format composite needs – like wind turbine blades or cabin covers – wider widths mean you produce more material with fewer cycles.

Here’s what one production manager told us after switching to our machine:

“We were running three small-scale units side-by-side to meet a single project demand. Now, we run one Grand Star machine and meet that demand faster, with lower energy use and fewer staffing requirements.”

Power consumption is also efficient. A 4400mm model only uses 13 kW – less than many air compressors on the same floor.

Don’t forget about uptime. With dual warp beam positions and large flange capacity, longer runs are possible before reloading. The electronically synchronized batching device ensures fabric rolls are cleanly collected and ready for finishing – again, with minimal manual intervention.

Why We Believe in This Technology

We’ve worked in this industry for years, and we’ve seen the shift firsthand – from manual-heavy production lines to lean, automated, smart factories. We designed our Glass fiber Multi axial machine with this shift in mind.

Here’s why our clients choose Grand Star:

✅ We offer tailored configurations based on material type, speed, and production goals

✅ Our support team is available for installation training and ongoing assistance

✅ Every machine is tested under simulated real-world conditions before shipment

✅ We care about energy use, reliability, and reducing your long-term operating costs

For us, it’s not just about selling a machine – it’s about solving problems and building long-term value. When you succeed, so do we.

Final Thoughts

Cutting production costs doesn’t always mean sacrificing quality. With the right technology – like the Glass fiber Multi axial machine – you can achieve both. Whether you’re scaling up or optimizing your current operations, this machine can help lower labor needs, reduce material waste, and improve your production flow. If you’re ready to take that step, we’re here to help you build a better, more cost-effective manufacturing future.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.