High Distance Double Raschel HD 6 50-250 (EL)

| High Distance Double Needle Bar Raschel Machine For Spacer – Warp knitting Machine | |

| Model No. | GS-HD6 50-250 |

| Ground Bars | 6 Bars |

| Bars Distance | 50-250 mm |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

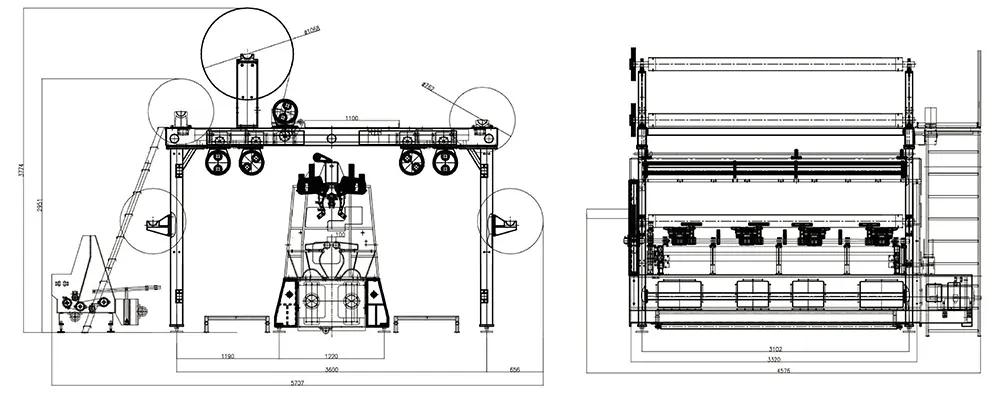

- TECHNICAL DRAWINGS

-

Working Width & Gauge:

- 2540 mm (100 inches) working width

- Gauge options: E16, E18, E22

-

Knock-Over Comb Bar:

- Distance adjustable from 50 mm to 250 mm

- Central trick plate distance readjustment

-

Knitting Elements:

- Two needle bars with latch needle units

- Two knock-over comb bars and two moveable stitch comb bars

- Six ground bars with stitch forming on GB3 and GB4

- Option for individual needle bars

-

Warp Beam Support:

- Standard 6 × 812 mm (32″) free-standing beam

- Optional 6 × 40″ free-standing beam

-

GrandStar® Command System:

- Operator interface for configuring and controlling machine functionality

-

Yarn Let-Off Device:

- Electronically controlled yarn let-off drive for each fully mounted warp beam

-

Fabric Take-Up:

- Electronically regulated fabric take-up with geared motor and four rollers

-

Batching Device:

- Separate rolling device

-

Pattern Drive:

- EN-drive with 6 electronic guide bar drives

- Shog distance: 18 mm (Ground), 25 mm (Pile)

- Optional electronic guide bar drive (EL), with up to 150 mm shog distance

-

Electrical Equipment:

- Speed-regulated drive with a total connected load of 7.5 KW

- Voltage: 380V ±10% (three-phase power supply)

- Main power cord: minimum 4m² (three-phase four-core)

- Ground wire: minimum 6m²

Training & Service

Installation & Training

We offer training in multiple formats, including on-site sessions in over 20 countries and dedicated local teams in key regions like Turkey, India, and the USA.

Local Service

Our after-sales service spans Turkey, India, Vietnam, Indonesia, and the USA, with plans for expansion. In regions without local teams, real-time online support is the first line of assistance, followed by dispatching engineers for hands-on support if necessary. Regular visits by our engineers every 1-2 months ensure machine performance, provide maintenance guidance, and promote operational stability.

Application

-

Textile Industry: Suitable for creating technical fabrics, upholstery, and high-quality garments that require intricate stitch patterns. Ideal for multi-level pattern production, especially with pile fabrics, offering versatility in fabric designs.

-

Home and Commercial Textiles: Excellent for manufacturing durable fabrics used in furniture, automotive upholstery, and more.

-

Garment Production: Works well for garments requiring detailed stitch and pile effects such as scarves, blankets, and outerwear.

-

Custom Textile Solutions: Capable of handling custom requirements for various pile heights and pattern complexities, making it ideal for specialized textile products.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |