After-Sales Service: The Hidden Value in an Industrial Textile Machinery Supplier

In today’s competitive textile market, choosing the right Industrial Textile Machinery Supplier goes far beyond machine performance. Many buyers focus on price or speed, but the real difference often appears after the sale. What happens when production stops or new fabric styles require quick adjustments? The answer lies in one hidden factor that defines long-term success – after-sales service.

Why After-Sales Service Decides Uptime And Profit

Downtime is the enemy of every mill. A machine that stops for two hours can erase a day’s margin. As an Industrial Textile Machinery Supplier since 2012, Grand Star Technology has seen the same pain points repeat across the industry: long waits for parts, unclear diagnostics, limited operator training, and service teams that do not know your fabric goals. We built our support model to remove these roadblocks so your machines keep knitting – and your orders keep moving.

From our base in Fujian, China, we serve customers across the United States, Japan, Turkey, Vietnam, Indonesia, India, Colombia, Mexico, and more. Global reach matters for service. It means parts and engineers are closer, response times are shorter, and advice is informed by thousands of installs, not one or two. Our local service teams in Turkey, India, Vietnam, Indonesia, and the USA handle on-site commissioning, preventive checkups, and escalation. In regions without a local team, we provide real-time online support first, then dispatch engineers from the nearest hub. Most issues get resolved fast because our electronic control systems report precise data to shorten troubleshooting.

- The Real ROI Of Strong Support

A strong after-sales program protects quality and lowers total cost of ownership. It does more than fix breakdowns – it prevents them. Our customer care program schedules checkups every 1 – 2 months to inspect wear parts, tune drives, and update control logic. The result is fewer unplanned stops, steadier fabric quality, and predictable maintenance windows you can plan production around. As an Industrial Textile Machinery Supplier, we measure success by your uptime, not only by machines shipped.

What “Service-First” Looks Like In Daily Operations

Our service starts on day one with installation and training. Operators learn not just buttons, but process logic: yarn paths, tension windows, and how patterning interacts with take-up and let-off. We deliver manuals, videos, online guidance, and on-site sessions tailored to your team. When your styles change, we help you re-parameterize quickly so you reach sellable fabric faster.

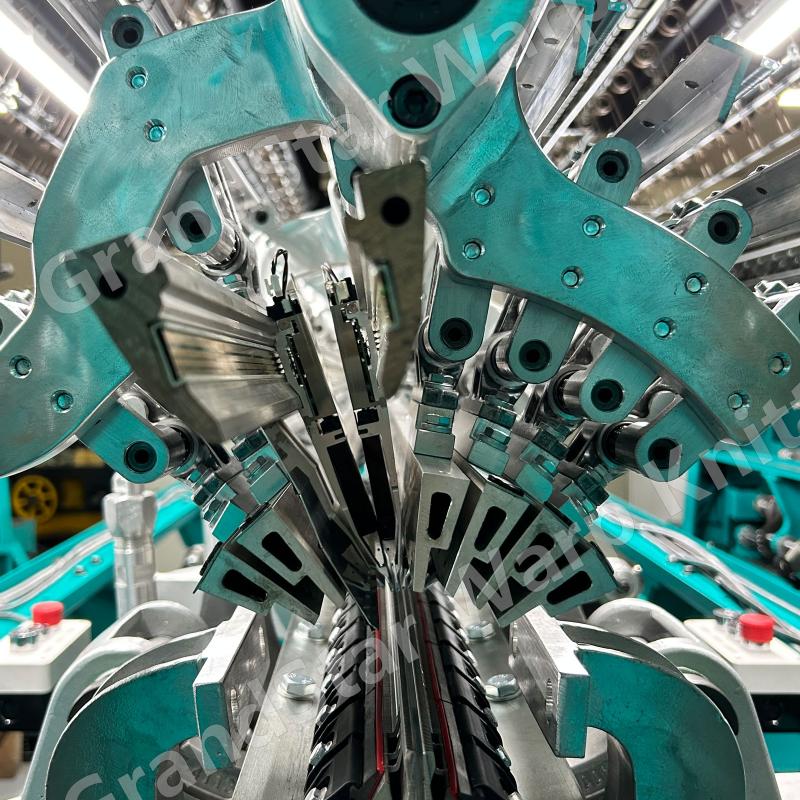

Inside the machine, support is embedded by design. Our integrated electronic platform – GrandStar® COMMAND SYSTEM – lets technicians configure and adjust functions from a clear interface. Drive speeds are regulated, yarn let-off is electronically controlled per warp beam, and fabric take-up uses a geared motor with four rollers for stable traction. These features simplify service because settings are consistent and auditable; they also stabilize fabric hand, which reduces rework.

Here are a few capabilities that reduce headaches for production managers and mechanics alike:

- Electronic guide bar drive with shogging up to 150 mm- repeatable patterning without mechanical guesswork.

- Speed-regulated main drive- smooth acceleration protects yarn and needles, and helps avoid start-mark defects.

- Heating and cooling via a circulating-air heat exchanger with a filter and dirt-monitoring system- cleaner oil, longer component life.

- Clear power specs- total connected load around 7.5 kW and standard 380 V±10% three-phase supply- easy facility planning.

- Designed For Stability, Tuned For Your Fabrics

Your applications drive our advice. Whether you produce jacquard fashion, upholstery, nets, or technical textiles, our warp knitting range – Raschel, Tricot, Double-Raschel, Lace, Stitch-Bonding, and Warping – covers the process. Key geometry matters for fabric outcomes, so we make the core mechanics adjustable and service-friendly: a working width around 3454 mm (136″), gauges available from E18 to E28, and a knock-over comb bar distance continuously adjustable from 2 – 12 mm. With multiple ground guide bars and a Piezo-Jacquard bar, plus two latch needle bars and matching comb bars, technicians have the levers they need to balance speed, pattern clarity, and yarn behavior. Warp beam support (7 x 812 mm free-standing) keeps tension stable, which shortens setup time after beam changes.

From Pain Points To Competitive Edge

Most mills tell us the same story: they don’t just need a machine; they need a partner who understands production risk. As your Industrial Textile Machinery Supplier, we focus on five risks that hit margins hardest – and how our after-sales service neutralizes them.

- Skill Gaps: Turnover happens. Our refresher training and remote coaching close gaps fast, so new operators reach standard quality without months of trial and error.

- Unplanned Stops: Condition-based checkups and parameter backups cut restart time. If a stop occurs, our diagnostics isolate faults quickly.

- Style Change Delays: When you switch to a new fabric, our team helps tune guide bar motions, take-up, and let-off, reducing waste while you dial in.

- Inconsistent Quality: Stable environmental windows- about 25 °C ±3 °C and 65% ±10% humidity- plus electronic controls reduce lot-to-lot drift. We help you set and keep those targets.

- Supply Chain Lag: Local teams and stocked consumables speed up parts delivery, so you are not waiting weeks for basics.

Not every section needs a checklist; sometimes it’s simple. Service is about people who answer the call, software that guides your team, and mechanical designs that are easy to maintain. It’s about confidence that your next order ships on time. That is the promise behind our machines and the reason customers in more than 20 countries trust Grand Star Technology.

Your Next Step

If you are reviewing vendors, include after-sales in your scoring matrix. Ask who will train your night shift, how parameters are backed up, and how often preventive visits occur. As an Industrial Textile Machinery Supplier, we welcome tough questions – they’re the right ones.

Call-to-Action: Ready to turn service into uptime and uptime into profit? Contact Grand Star Technology for a plant walk-through, a service-readiness audit, or a demo of our GrandStar® COMMAND SYSTEM. We’ll map your current pain points to a clear improvement plan and help your knitting lines run smoother, longer, and smarter.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.