Step-by-Step Tutorial for Malivlies Stitch Bonding Machine Users

Malivlies Stitch bonding machine users want consistent, saleable fabric from the very first run. At Grand Star Technology, we design, build, install, and support these lines for textile and nonwoven producers. This practical guide shows how to set up, operate, and maintain the Malivlies Stitch bonding machine, and explains the options that let your plant scale without chaos.

Why the Malivlies Stitch Bonding Machine Ensures Stability

Downtime, uneven stitch geometry, and slow changeovers squeeze margins. We address these issues at the machine level. An integrated computer system coordinates the main drive, yarn feeding, and fabric take-up, so ramp-up is smooth and repeatable. Operators use an intuitive touch screen to see live data and act before small variations become quality claims. That combination helps new teams learn faster and experienced crews work with fewer adjustments.

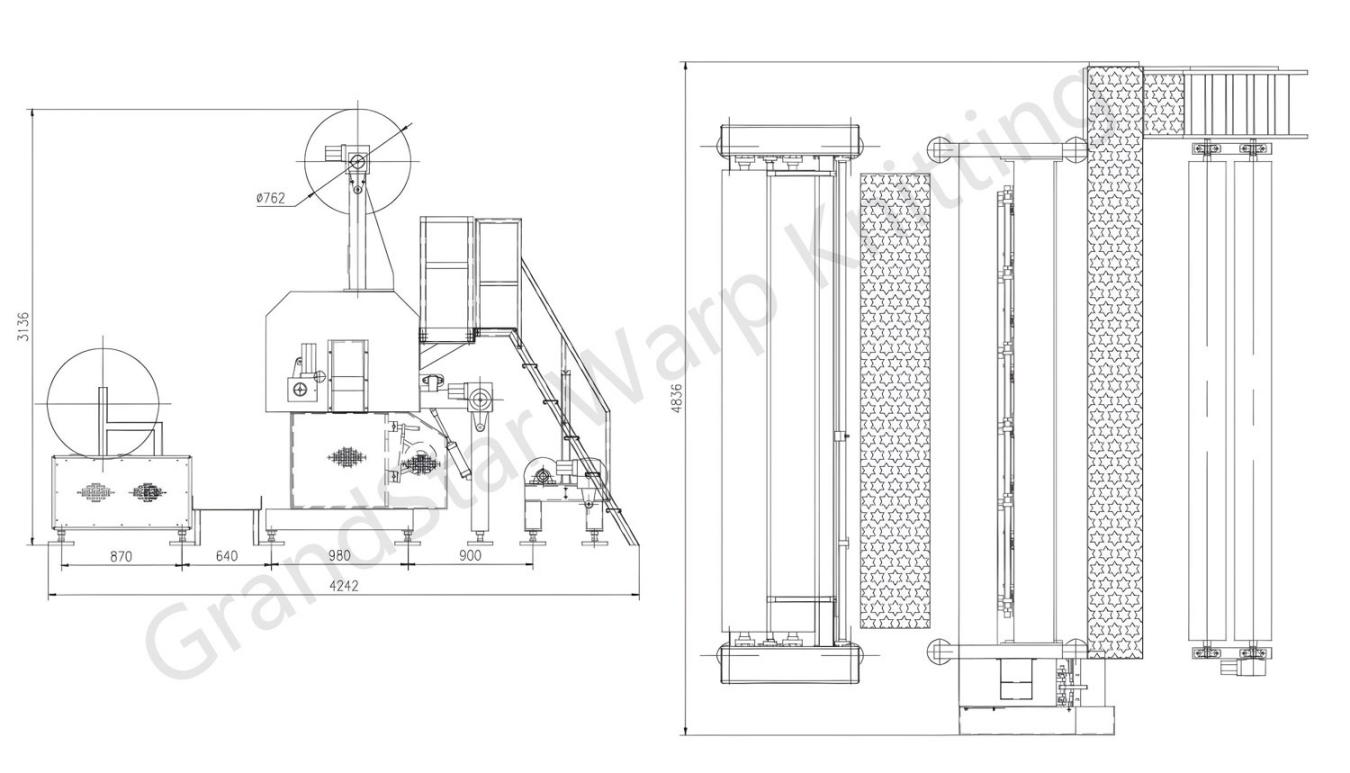

Planners care about power and layout. For the Malivlies Stitch bonding machine, we specify two main-motor ranges tied to machine width: 13 KW for 2000-4400 mm and 18 KW for 4400-6000 mm. A speed-regulated drive with power-failure safety protects work in process, while a single speed control via frequency converter keeps day-to-day operation simple. If you are comparing options and need a Malivlies stitch bonded fabric production guide, the following steps will help you standardize recipes across shifts and locations.

✅ Core Applications with Fast Payback

- Stitch-bonded fabrics for durable industrial and consumer goods

- Medical bandages where stability and clean edges matter

- Clothing interlining with reliable dimensional control

- Curtain fabric for interior and furnishing programs

✅ Key Electrical and Safety Design

- Speed-regulated drive with power-failure protection

- Single speed control for primary functions via frequency converter

- Clear operator interface for faster training and fewer errors

Step-by-step Guide to Confident Start-up

Step 1 – Prepare yarns and beams. Confirm yarn specs and beam build before threading. The frame supports 1 or 2 warp beam positions for sectional use, with a maximum flange diameter of 30. Clean creels and correct tension at the start reduce end breaks later.

Step 2 – Select working width and gauge. Match the working width to the order: 2000, 2800, 3600, 4400, 4800, 5400, or 6000 mm. Then choose the gauge for feel, weight, and throughput: F7, F12, F14, F16, F18, F20, or F22. This decision shapes the hand of the fabric and the speed you can run.

Step 3 – Verify knitting elements. Install and align the compound needle bar, closing wire bar, knock-over sinker bar, supporting bar, counter-retaining bar, and one or two ground guide bars. Good alignment builds a clean stitch structure and prevents pattern drift.

Step 4 – Configure the pattern drive. Use the N-drive with a pattern disc and the integrated tempi change gear drive to set motif and stitch density. A single pattern disc gives enhanced functionality with a straightforward setup. Start with your standard disc; adjust tempi to hit your target GSM and handle.

Step 5 – Thread and set yarn let-off. The electronically controlled yarn let-off drive uses a geared motor with a frequency converter for precise tension. For sensitive programs, add the optional electronically controlled yarn stop motion to halt the line on a yarn fault and protect quality.

Step 6 – Dial in fabric take-up and batching. The electronically controlled fabric take-up – also driven by a geared motor with a frequency converter – keeps winding stable. For standalone batching, use the friction drive with a pressure roller. The system supports a maximum batch diameter of 914 mm (36″) and includes a geared motor with an integrated frequency converter for uniform roll build.

Step 7 – Run a trial, inspect, and lock the recipe. Start slow. Check edges, stitch stability, and tension balance across the width. Use the touch screen to review live readings, make small trims, and then lock your settings. This “trial → inspect → adjust” loop is simple, repeatable, and effective for both new articles and repeat orders.

✅ Quick Setup Parameters

- Working width options: 2000, 2800, 3600, 4400, 4800, 5400, 6000 mm

- Gauge options: F7, F12, F14, F16, F18, F20, F22

- Pattern Drive-N: N-drive + pattern disc; integrated tempi change gear; single pattern disc

- Warp beam support: 1-2 positions; max flange Ø30

- Yarn let-off: Electronic drive; geared motor + frequency converter

- Yarn stop motion: Optional electronic control

- Fabric take-up: Electronic; geared motor + frequency converter

- Batching (standalone): Friction + pressure roller; max Ø914 mm (36″); geared motor with integrated frequency converter

In daily production, these parameters become the backbone of your standard work. We see the best results when teams document the chosen gauge, tempi settings, yarn type, and take-up speed on the route card for each SKU. That single habit shortens changeovers and cuts scrap.

Service, training, and scale with Grand Star Technology

Reliability is the sum of smart design and strong support. The Malivlies Stitch bonding machine ships with speed-regulated drives, power-failure safety, and a clear operator interface. But what protects your schedule is the way we stand behind the line. Technical support is a cornerstone of our warp-knitting services. Your teams get detailed professional manuals, online guidance, and an instructional video library for fast learning. We also provide on-site training tailored to your specific product mix – whether you run medical bandages, interlining, or curtain fabric.

In regions without a local service team, our first response is real-time online support. If hands-on help is required, we dispatch engineers from the nearest hub directly to your site. This keeps issues contained and helps you bring new SKUs online on time. Plants looking for the best stitch bonding machine for nonwovens often tell us that service coverage matters as much as features; we agree, and we built our model accordingly.

✅ Service & Training that Cut Downtime

- Installation guidance plus on-site training tailored to your line

- Manuals, online support, and a video library for rapid onboarding

- Regional engineer dispatch when hands-on support is required

As you scale, keep a close eye on the simple levers: width selection, gauge selection, and pattern tempi. These determine output and hand feel more than any other settings. Use the electronic yarn let-off and fabric take-up to hold tension steady, and apply the optional yarn stop motion for sensitive constructions. With those controls in place, the Malivlies Stitch bonding machine will deliver stable quality at commercial speed.

Call to Action: Ready to standardize quality and speed across shifts? Contact Grand Star Technology to configure a Malivlies Stitch bonding machine – choose your width, gauge, and pattern drive – and schedule a guided start-up with our engineers. If you need a deeper stitch bonding machine for nonwovens playbook, ask us for a plant-ready checklist based on your yarn, GSM, and end use.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.