Why You Need the Maliwatt Machine to Improve Precision and Speed

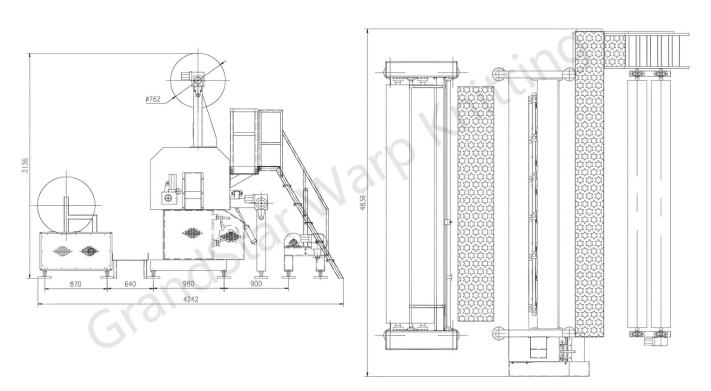

The Maliwatt Machine is a high-performance industrial machine designed to enhance precision and speed in fabric production. It uses advanced technology for precise yarn feeding, fabric take-up, and pattern control, ensuring consistent, high-quality output. Ideal for industries like textiles and medical fabrics, the Maliwatt Machine offers customizable options in terms of working width and yarn control. It’s designed to improve efficiency, reduce downtime, and streamline manufacturing processes, making it a vital tool for companies looking to optimize their production lines. Whether you’re dealing with complex fabrics or large production volumes, the Maliwatt Machine delivers consistent, high-quality results. But how exactly does it work, and why is it a must-have for modern manufacturing? Let’s dive into the key features that make this machine essential for improving your production line’s performance.

Boosting Precision with Advanced Technology

Precision is a non-negotiable requirement for modern manufacturing. The slightest error in measurement or production can result in costly defects, delays, and wasted resources. This is where the Maliwatt Machine stands out. Equipped with cutting-edge technology, it allows manufacturers to achieve extremely precise results in every batch.

- Unmatched Accuracy in Every Production Cycle

The Maliwatt Machine uses advanced control systems that ensure accurate and consistent performance. With its electronically controlled yarn let-off and fabric take-up systems, manufacturers can achieve precise fabric tension control, reducing the risk of errors caused by inconsistent feeding.

- Electronically controlled yarn let-off offers greater precision in yarn tension.

- Integrated computer system for seamless control of main drive, yarn feeding, and fabric take-up.

- High-quality fabric production for demanding applications such as medical bandages and durable textiles.

These features help ensure that every unit produced meets the highest standards, ultimately improving the overall quality of your final product.

- Ensuring Consistency Across Large Batches

Whether you’re producing small or large volumes, consistency is key. The Maliwatt Machine integrates a single pattern disc for enhanced functionality, ensuring that the same pattern is accurately replicated across all units, no matter the scale of the production. This consistency is crucial when producing complex fabrics for industries such as healthcare, fashion, and interior design.

Accelerating Production Speed Without Compromising Quality

In today’s fast-paced manufacturing environment, speed is just as important as precision. The Maliwatt Machine is designed to enhance productivity while maintaining the highest levels of quality.

- Faster Production with Advanced Motion Control

One of the standout features of the Maliwatt Machine is its advanced motion control system, which enables faster fabric production without sacrificing accuracy. The machine’s speed-regulated drive and frequency converter allow for smooth and rapid operation, significantly reducing downtime and maximizing output.

- Speed-regulated drive for consistent performance.

- Geared motor with frequency converter for better control and faster operation.

- Higher operational efficiency, meaning faster turnaround times for your customers.

The ability to operate at high speeds while maintaining top-notch precision makes the Maliwatt Machine a valuable addition to any manufacturing process, especially when meeting tight deadlines.

- Scalable for Different Production Needs

Whether your production needs are small or large, the Maliwatt Machine adapts to your requirements. With its flexible working width options (ranging from 2000mm to 6000mm), the machine can handle a variety of fabric types and sizes, making it ideal for diverse applications.

Enhanced Reliability and Service Support

Investing in the Maliwatt Machine goes beyond just improved precision and speed. Grand Star ensures that the reliability of the machine is backed by comprehensive training and after-sales service to guarantee that your production line operates smoothly.

- Comprehensive Training and Installation Support

Our commitment to your success doesn’t stop at the installation of the Maliwatt Machine. We provide thorough warp knitting training and installation support, ensuring that your team is well-prepared to operate the machine efficiently. With professional manuals, instructional videos, and real-time guidance, we make sure you’re equipped with the knowledge needed to optimize your production

- Reliable After-Sales Service for Peace of Mind

Even after the machine is up and running, Grand Star offers robust after-sales support. Our local service teams are ready to provide real-time assistance, and in regions where on-site support is unavailable, our engineers are just a call away. This means that any operational hiccups can be addressed quickly, minimizing downtime and maintaining production momentum.

- Real-time online support for immediate troubleshooting.

- On-site service from our engineers ensures minimal disruption.

- Comprehensive after-sales service to keep your machine running at peak performance.

By offering both reliable machinery and unmatched service, Grand Star ensures that the Maliwatt Machine remains an asset to your production for years to come.

Ready to Enhance Your Production Line?

If you’re ready to improve precision, speed, and overall efficiency in your manufacturing process, the Maliwatt Machine is the solution you’ve been looking for. With its advanced features, reliable performance, and top-tier service, it’s time to take your operations to the next level. Contact Grand Star today to learn more about how the Maliwatt Machine can transform your production capabilities.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.