Why Choose a Maliwatt Stitch Bonding Machine for Production

Maliwatt Stitch Bonding Machine sits at the heart of stable, scalable textile production. It delivers consistent loops, fast changeovers, and clean edges. Energy use stays predictable. Operators get control, not guesswork. Defects drop. Lead times shrink. That is the surface. Beneath it are design choices that make the difference on a noisy shop floor: smarter pattern control, precise yarn tension, and a take-up system that keeps fabric calm. Why do these details matter now, when costs are rising and orders are volatile? In the next section, we open the machine and show what really protects your margins.

Built For Real Manufacturing Pain Points

Across home textiles, apparel components, and medical disposables, producers face the same hurdles: unstable fabric handfeel, long changeover times, operator skill gaps, and rising energy costs. A Maliwatt Stitch Bonding Machine addresses these realities with stable mechanics and computer-assisted control, so quality does not depend on a single expert at the line.

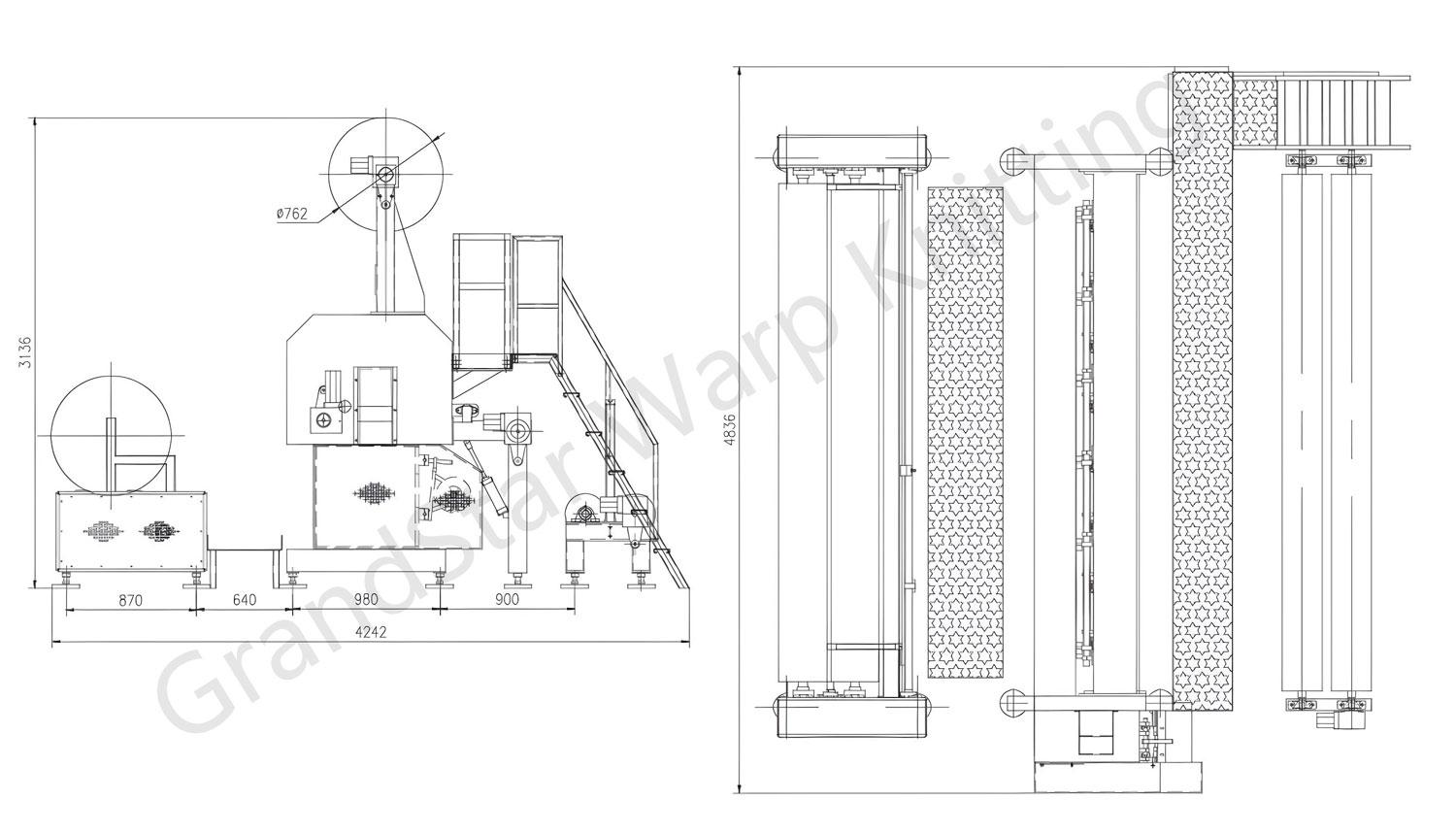

Our platform supports working widths of 2000, 2800, 3600, 4400, 4800, 5400, and 6000 mm, giving planners freedom to align loom width to order size and waste targets. Gauge options – F7, F12, F14, F16, F18, F20, F22 – help you tune stitch density for anything from robust industrial webs to delicate medical bandages. The machine core combines a compound needle bar, closing wire bar, knock-over sinker bar, supporting bar, and counter-retaining bar, plus 1 or 2 ground guide bars. The result is clean loop formation and fewer off-grade rolls.

Power is sized for production floors: 13 KW main motor for 2000 – 4400 mm widths and 18 KW for 4400 – 6000 mm widths, with speed-regulated drives and power-failure safety to protect work-in-process. Operators manage all primary functions through a single frequency converter, so ramp-ups are smooth and predictable – key for energy and waste reduction.

- Motion And Pattern Control That Reduce Setup Time

Repeatable patterns are vital when you scale. Our N-drive with a pattern disc provides stable, mechanical repeatability. An integrated tempi change gear drive and single pattern disc simplify adjustments without tearing down the setup. Machine control is handled by an integrated computer system that synchronizes the main drive, yarn feeding, and fabric take-up, while an intuitive touch screen displays real-time production data. Shorter setup, fewer surprises.

- Yarn, Take-Up, And Batching Designed For Consistency

Feed and winding control are frequent sources of defects. We use electronically controlled yarn let-off with a geared motor and frequency converter for precise tensioning. An optional electronically controlled yarn stop motion adds an extra safeguard when working with sensitive yarns. Downstream, an electronically controlled fabric take-up – also frequency-regulated – keeps surface appearance uniform. For end-of-line handling, the standalone batching device uses friction drive with a pressure roller, supports batches up to 914 mm (36″), and runs on a geared motor with integrated frequency converter. It’s a compact, reliable path from web to roll.

Flexible Configuration For Diverse Products

Whether you are quoting an industrial stitch-bonded fabric or scheduling medical bandage output, flexibility pays. Our warp beam support accepts 1 or 2 positions for sectional use, up to 30 maximum flange diameter, so you can stage different yarn counts or colors without cluttering the aisle.

In practice, that flexibility unlocks these core applications:

- Stitch-Bonded Fabrics- Durable webs for filtration, automotive, and construction where dimensional stability matters.

- Medical Bandages- Clean edges and uniform stretch for healthcare converters.

- Clothing Interlining- Stable, durable interlinings that keep garment shape through sewing and wear.

- Curtain Fabric- Precise stitching patterns for consistent drape and light control.

Production managers often ask about industrial stitch bonding machine price and the cost-to-quality balance. While price matters, the bigger lever is scrap and rework. With stable yarn control, synchronized take-up, and repeatable patterning, the Maliwatt Stitch Bonding Machine reduces defect rates that silently erode margins. That is why many customers see ROI not only from higher speed, but from fewer off-quality meters and faster changeovers.

For plants operating mixed product portfolios, gauge and width choices prevent over- or under-utilizing assets. You can assign F22 gauges to finer medical substrates and reserve F7 – F12 for heavy webs, all within a common control philosophy and operator interface. That shared interface also accelerates cross-training – important when staffing is tight.

- If you need quick color or yarn swaps, 1- 2 warp beam positions keep you agile.

- If you run long campaigns, the batching device up to 914 mm reduces roll changes and keeps uptime high.

- If you manage complex order books, the touch screen with live data helps supervisors react before small drifts become defects.

Service, Training, And A Partnership Mindset

At Grand Star Technology, buying a Maliwatt Stitch Bonding Machine is the start of a partnership. We know that machines do not create value unless teams can run them with confidence. That’s why we provide warp knitting training, installation & training, and a deep knowledge base: professional manuals, online guidance, and instructional video libraries. When on-site help is best, we deliver on-site training sessions tailored to your needs.

Service coverage is practical and responsive. Where we maintain local teams, you get local service. Where we do not, we begin with real-time online support and, if needed, dispatch engineers from the nearest service hub for hands-on assistance. This approach keeps your line moving, whether the issue is an operator question or a mechanical tune-up.

For operations leaders evaluating high-speed stitch bonding for medical bandages or interior textiles, the case is straightforward: precision yarn control, dependable take-up, and patterning that scales – backed by training that sticks. The Maliwatt Stitch Bonding Machine was engineered to reduce variability, shorten learning curves, and stabilize output across shifts.

Final Words

Ready to benchmark your current line against a Maliwatt setup? Contact Grand Star Technology for a technical consultation, a configuration review (width and gauge selection), and a sample-run plan aligned to your target fabrics. Let’s turn predictable quality – and lower total cost per meter – into your competitive advantage.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.