Multi Axial Warp Knitting Machine Accelerates Composites Growth

The demand for lighter, stronger, and more efficient composite materials continues to rise across industries like aerospace, wind energy, and automotive manufacturing. To meet this growing need, manufacturers are turning to advanced technologies that can deliver high-performance textiles faster and more consistently. One of the most game-changing solutions in this space is the multi axial warp knitting machine. This machine isn’t just about automation – it represents a shift in how industrial textiles are engineered and produced. With its ability to create layered, multi-directional fabrics, the multi axial warp knitting machine offers a reliable foundation for composite structures that require both flexibility and strength.

Why Multi Axial Knitting

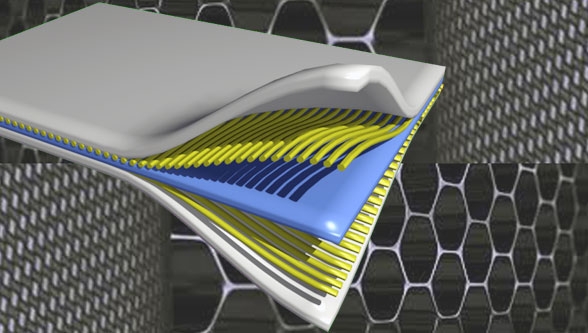

If you’ve ever been involved in composite production, you already know that the foundation of every high-performance part begins with the fabric. Whether it’s a 60-meter wind turbine blade or a lightweight aerospace panel, the strength, flexibility, and durability of that component depend heavily on how the textile layers are structured. Poor alignment or inconsistent fiber angles can lead to weak points, material failure, or excessive weight – none of which are acceptable in today’s demanding applications. That’s precisely where the multi axial warp knitting machine makes a difference. Unlike traditional weaving or unidirectional layup methods, this advanced knitting system offers unmatched flexibility in fabric architecture. It allows fibers to be inserted at specific angles – like 0⁰, ±45⁰, and 90⁰ – and bonded together in a single continuous process. These multi-directional orientations greatly improve the mechanical performance of composite parts, particularly under complex stress and load conditions.

Using a multi axial warp knitting machine, manufacturers can create customized textile reinforcements that match the exact stress profiles of their final products. The servo-controlled weft insertion system places fibers with incredible precision, while the integrated chopper unit ensures clean, consistent cuts for chopped strand layers. This results in enhanced control over weight distribution, thickness, and tensile strength. Speed is another key advantage. With electronic let-off and take-up systems, modern multi axial machines operate at high efficiency while maintaining consistency. Compared to manual layups or less automated systems, these machines reduce production time significantly – often cutting lead times by 30 to 50%. For manufacturers racing to meet tight deadlines or scale production, that’s not just helpful – it’s transformative.

Beyond the technical benefits, there’s also a business case. Less waste, fewer labor hours, and better quality control translate into real savings. In competitive industries where margins are tight and innovation is constant, investing in a multi axial warp knitting machine isn’t just about better fabrics – it’s about future-proofing your production. From wind energy to automotive panels, composite manufacturers are embracing this technology not just because it works – but because it works smarter.

What Sets Grand Star‘s Machines Apart

At Grand Star, textile innovation isn’t just something we do – it’s who we are. With decades of experience in the development and manufacturing of advanced textile machinery, we’ve earned the trust of composite manufacturers worldwide. But we’ve never been content to simply deliver machines. Instead, we focus on creating lasting partnerships by helping clients meet real-world production challenges with confidence. Our multi axial warp knitting machine reflects this philosophy. Designed from the ground up for modern composite needs, it brings together high-precision engineering, intelligent automation, and flexible configuration options – all within a compact, reliable platform.

So, what truly sets our machines apart?

✅Adjustable working widths ranging from 2565mm to 4496mm make it easy to produce both narrow reinforcement fabrics and extra-wide composite textiles for large components like wind blades.

✅E7 gauge compound needle bars guarantee consistent fabric structure, critical for load-bearing applications that require uniform tension and alignment.

✅Our machines feature electronically controlled yarn let-off and fabric take-up systems, ensuring optimal yarn tension and smooth fabric flow during every production run.

✅The servo-driven weft insertion system and precision chopper unit enable accurate fiber placement and customized layering, essential for producing high-performance, multi-angled textile composites.

✅With an intuitive touchscreen control interface and advanced motion control, operators can easily manage key parameters such as yarn delivery rate, stitch density, and fabric tension in real time.

Additional innovations include dual warp beam support, N-drive pattern control, and synchronized batching systems, all engineered to maximize uptime and fabric consistency. Whether you’re producing high-volume orders or small-batch custom textiles, our machines are built to handle the load – literally.

But beyond the specs, what we hear most from our clients is how our machines perform under pressure. In real factories, under tight timelines, with demanding specs – our multi axial warp knitting machine consistently delivers. It reduces the need for manual intervention, maintains high product quality, and enables manufacturers to scale with confidence.

That’s why we believe the best technology isn’t just precise – it’s practical. And that’s exactly what we build.

The Future of Fabrication Is Smart, Fast, and Custom

The future of manufacturing is being reshaped by innovation – and nowhere is that more evident than in the world of composites. As industries push toward lighter, stronger, and more sustainable solutions, fiber-reinforced materials are stepping into the spotlight. From aerospace and automotive to renewable energy and advanced infrastructure, composite components are being relied on to deliver high performance under extreme conditions.

But as the demand rises, so does the pressure on manufacturers to produce smarter, faster, and more cost-effectively. Traditional methods often fall short – either in speed, scalability, or precision. That’s why the multi axial warp knitting machine has become such a critical tool in modern fabrication.

Unlike conventional systems, this machine doesn’t force manufacturers to choose between speed and customization. It offers both. With electronically controlled systems and servo-driven mechanics, the multi axial warp knitting machine allows real-time adjustments, precise fiber placement, and minimal material waste – all while maintaining a high production output.

What does that mean on the factory floor?

✅Faster throughput, reducing lead times and boosting capacity

✅Flexible fiber orientations, ideal for meeting complex structural requirements

✅Lower waste and material costs, thanks to more accurate layer control

✅Real-time process control, putting operators in full command of quality

The result is a textile production system that’s not only technically advanced but also business-smart. It empowers manufacturers to adapt quickly, respond to market shifts, and maintain consistency without slowing down.

At Grand Star, we understand that innovation doesn’t stop at the machine. That’s why we’re constantly evolving – listening to our partners, improving our engineering, and ensuring every multi axial warp knitting machine we build can meet tomorrow’s challenges today. Whether you’re producing high-precision composite panels for aerospace or durable structural reinforcements for wind turbines, our technology is built to help you do it better, faster, and more efficiently. Because in the future of fabrication, customization and speed aren’t luxuries – they’re necessities.

And with Grand Star by your side, you’re already a step ahead.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.