Raschel Jacquard Textile with fallplate RJPC 4F

| Jacquard Raschel machine RJPC 4/1F with fallplate for curtains / outerwear – Warp Knitting Machine | |

| Model No. | RJPC 4 F (EL) |

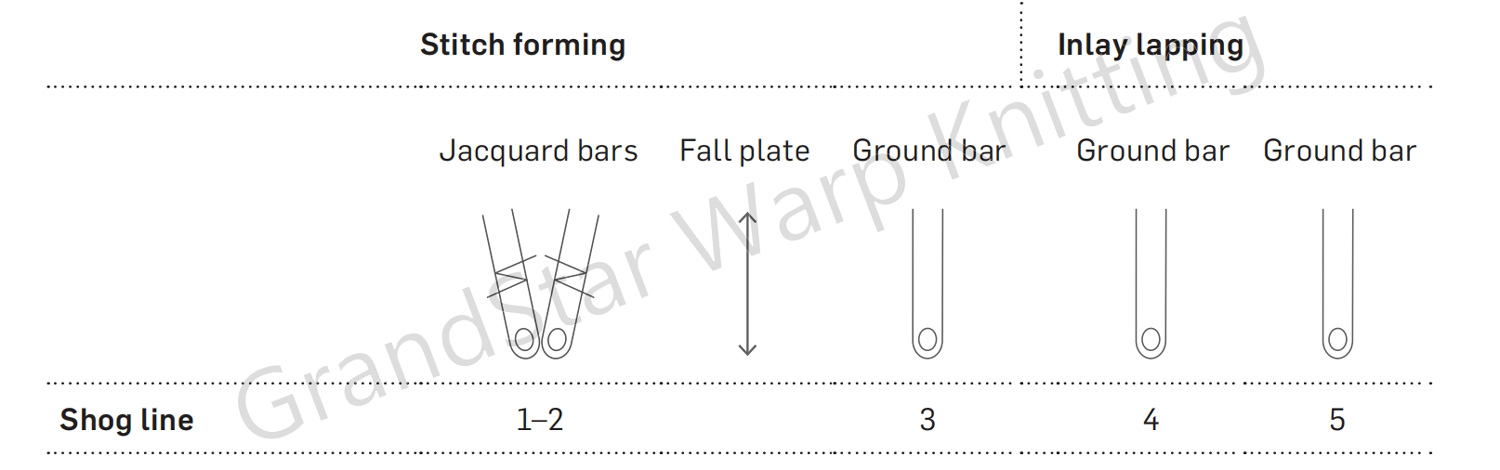

| Ground Bars | 4 Bars |

| Jacquard Bars | 1 Groups (2 Bars) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

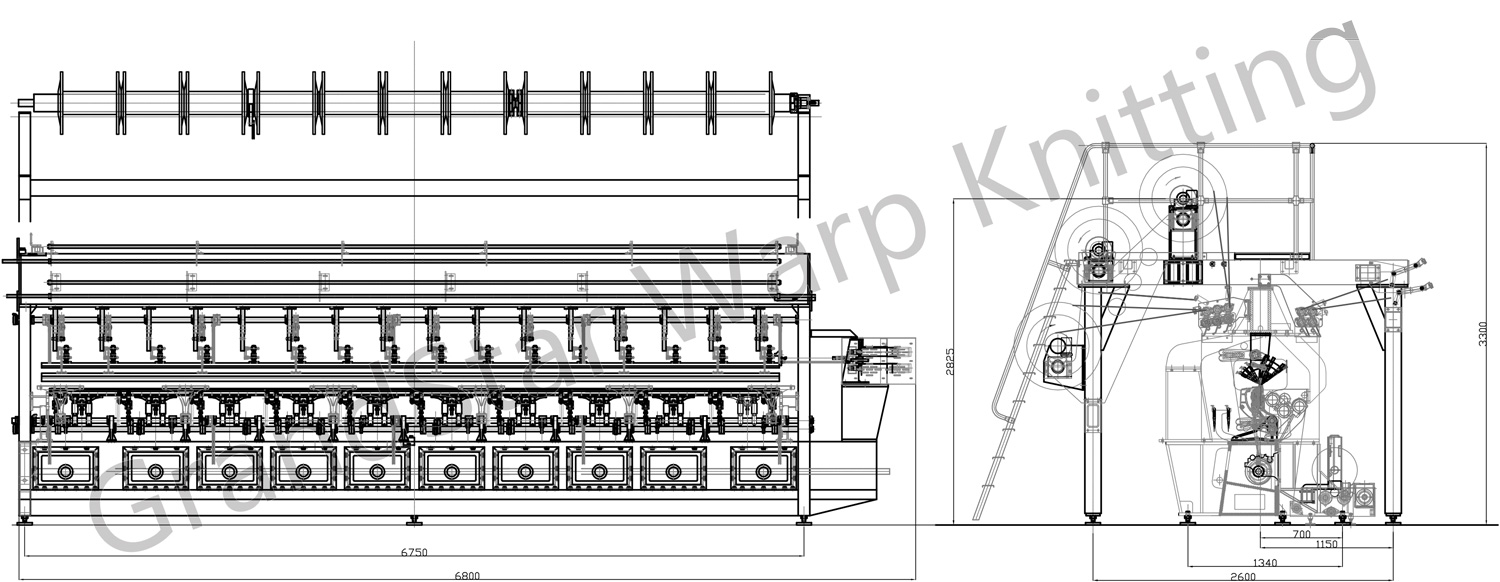

- TECHNICAL DRAWINGS

Working Width / Gauge:

6300 mm (248 inches), available in E18 and E24 gauges.

Yarn Let-Off Device:

Features three electronically controlled let-off devices for ground guide bars with multi-speed functionality.

Pattern Device EL:

Fully electronic guide bar control for ground and Jacquard bars to achieve precise patterning.

GrandStar® Command System:

Intuitive operator interface for configuring and controlling all machine functionalities electronically.

Fabric Take-Up:

Electronically regulated system with four rollers covered in black grip tape, driven by a geared motor for precision.

Batching Device:

Independent rolling unit with a maximum diameter of 685 mm (27″).

Electrical Equipment:

Speed-regulated drive with 7.5 KW total load, powered by a 380V ±10% three-phase supply.

Working Conditions:

Optimal operation at 25℃ ±3℃ temperature, 65% ±10% humidity, and 2000–4000 KG/㎡ floor pressure.

Creel:

Custom-designed yarn supply system tailored for Jacquard functionality.

Training & Service

Installation & Training

Our technical support spans local service teams, online resources, and on-site training to enhance machine performance across global markets.

Local Service

Application

- Home Textiles: Perfect for producing curtains, bed linens, and upholstery fabrics.

- Technical Textiles: Used for crafting mesh, nets, and filtration fabrics.

- Apparel Manufacturing: Ideal for making intricate Jacquard patterns for high-fashion and sportswear.

- Automotive Industry: Produces robust fabrics for interior linings and protective covers.

- Medical Textiles: Suitable for creating specialized fabrics for healthcare applications.

- Industrial Use: Used for high-durability textiles in construction and agriculture.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |