Why Tricot Knitting Equipment with Jacquard Bars Is Essential for Precision

In the world of textile manufacturing, Tricot knitting equipment plays a crucial role in creating high-quality fabrics with intricate designs. Among the various features that enhance the machine’s performance, Jacquard bars stand out as essential components. These specialized bars are a key to achieving precise, consistent knitting results. In this article, we will explore why Tricot knitting equipment with Jacquard bars is a game-changer for precision in textile production, and how it can elevate the quality and efficiency of your operations.

The Power of Precision in Tricot Knitting

Precision is the cornerstone of modern textile production, especially when it comes to producing fabrics for high-end fashion, performance textiles, and industrial applications. The demands for perfect stitching, tight tolerances, and intricate patterns are constant. Without precise control over the knitting process, these expectations cannot be met.

This is where Tricot knitting equipment with Jacquard bars comes into play. Jacquard bars are designed to offer high levels of accuracy by allowing the individual control of each needle in the machine. They ensure that the patterns and structures are woven into the fabric with unparalleled precision. With compound needles in the individual needle bar, as well as specialized features like the slider and sinker bars, manufacturers can now achieve consistently high-quality results that meet the exact specifications required for premium fabrics.

Key Features That Enhance Precision:

- Individual Needle Bar: Equipped with compound needles for highly accurate and precise knitting.

- Slider Bar: Includes plate slider units, which offer stability and precise movement for smooth knitting.

- Sinker Bar: Compound sinker units that guarantee accuracy and consistent fabric tension.

- Guide Bars: Made from carbon-fiber-reinforced materials, these bars improve durability and reduce machine weight for better control during operation.

How Jacquard Bars Improve Fabric Quality

Jacquard bars are not only important for precision in knitting; they also have a direct impact on the overall fabric quality. In the context of Tricot knitting equipment, the Jacquard bar system enables operators to create complex patterns and intricate designs. Whether you’re producing high-fashion fabrics, technical textiles, or performance garments, Jacquard bars make it possible to craft designs that were previously difficult or impossible to achieve.

- Enhanced Control Over Fabric Design

By using Jacquard bars, each yarn guide can be adjusted to move independently. This level of control allows for more intricate patterns and textures to be incorporated into the fabric without compromising on quality. It also reduces the likelihood of fabric defects, ensuring that the finished product is uniform and meets the highest standards.

- Laserstop: An integrated system that immediately detects faults, preventing production errors before they occur.

- Camera Monitoring: Provides real-time monitoring of fabric quality, ensuring consistency in every batch.

This precision not only improves the aesthetic appeal of the fabric but also its functional performance. For example, in the case of performance textiles, the ability to knit fabrics with consistent stretchability and breathability is key to creating functional sportswear.

Efficiency and Reliability in Production

Apart from precision, the efficiency and reliability of Tricot knitting equipment with Jacquard bars are crucial for any textile manufacturer. The ability to maintain high-speed production while ensuring accurate and uniform fabric quality leads to increased productivity and reduced waste. This is particularly important when dealing with large-scale manufacturing and tight deadlines.

The Grand Star® Command System enhances this by giving operators the ability to control and configure all electronic functions with ease, offering more streamlined management of the production process. The equipment’s electronic features also include a regulated fabric take-up system, which ensures smooth fabric handling and helps to minimize errors.

- Increased Durability and Reduced Downtime

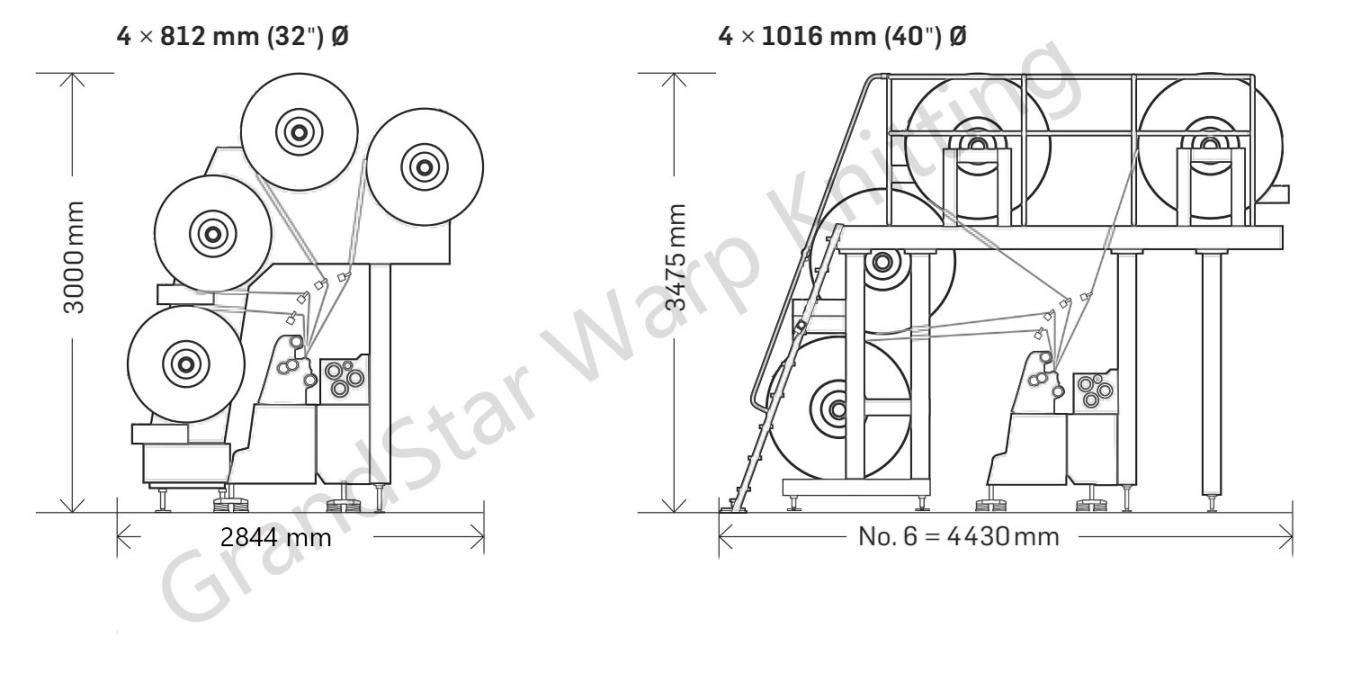

The combination of carbon-fiber-reinforced guide bars and the machine’s other durable components, like the sinker and slider bars, ensures that the machine performs reliably over time. Reduced machine weight and enhanced stability contribute to smoother operations with minimal wear and tear. Additionally, the Warp Beam Support setup, with flexible configurations, ensures that the equipment can handle various production requirements without sacrificing quality or efficiency.

- Yarn Let-off Device: Electronic control of yarn tension ensures consistent thread feed, reducing inconsistencies.

- Geared Motor System: Regulates fabric take-up to ensure smooth, accurate handling, reducing downtime caused by fabric handling errors.

Take Your Fabric Production to the Next Level

With the continuous evolution of the textile industry, the demand for precision, quality, and efficiency is only increasing. By incorporating Tricot knitting equipment with Jacquard bars into your production line, you are not only ensuring precision but also enhancing the overall reliability and performance of your textile operations.

At Grand Star, we offer cutting-edge Tricot knitting equipment designed to meet the ever-growing needs of the textile market. Our machines are equipped with advanced features like Jacquard bars, integrated monitoring systems, and precise electronic control, ensuring you get the best in both quality and efficiency. Contact Grand Star today to learn more about how our innovative Tricot knitting machines can elevate your textile production. Let us help you achieve the precision and consistency your business demands.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.