Why Invest in a Tricot Knitting Machine For Fabric Today

Thinking about upgrading your knitting line? Tricot Knitting Machine For Fabric could be the shift that changes everything. It delivers stable quality. It speeds up style changes. It lowers waste. Your team gets clearer control and fewer surprises. Buyers notice the difference in hand, drape, and consistency. Costs become predictable. Lead times shrink. But the real win isn’t just higher output. It’s what the machine unlocks in design freedom and margin. What makes this system different from a regular tricot setup? And how fast does it pay back on a real shop floor? Let’s lift the cover and see.

Stable Output, Faster Changeovers

Most plants face the same daily friction: quality drift, unplanned stops, and long changeovers. Energy is expensive. Orders are smaller and more frequent. Buyers want richer patterns without extra defects. A Tricot Knitting Machine For Fabric addresses these pressures through tight mechanics and simple, robust controls.

✅ Problems Mills Actually Face

- Quality Drift: The Individual Needle Bar uses compound needles that hold stitch geometry over long runs, so shade and hand stay consistent.

- Unplanned Downtime: Laserstop and an Integrated Camera find faults early. Operators see the cause, act quickly, and waste less fabric.

- Tension Variation: Each warp beam position includes an electronically controlled yarn let-off, which keeps tension uniform and thread feed steady.

- Slow Style Changes: The N-Drive with three pattern discs and tempi change gear trims setup time. Choose EL-Drive for electronic shogging of all guide bars up to 50 mm (optionally 80 mm) to reach complex patterns without mechanical rework.

What you do not see is just as important. The Slider Bar with ½″ plate sliders and the Compound Sinker Bar steady the web. Two Guide Bars use carbon-fiber-reinforced guide units to cut weight and vibration, improving precision at speed. The result is fewer corrections, less rework, and a cleaner fabric face right off the machine.

From a cost lens, the speed-regulated drive (total connected load 25 kVA) and oil/water heat exchanger help manage energy and temperature. You get higher throughput without damage to the hand or finish. That is why brands in fashion, sportswear, and automotive treat a high-speed tricot knitting machine for sportswear as a growth tool, not just a replacement.

Inside The Grand Star Tricot With Weft Insertion

Performance is the sum of many parts working in step. Our platform is designed so operators can set up once, run long, and change over with confidence.

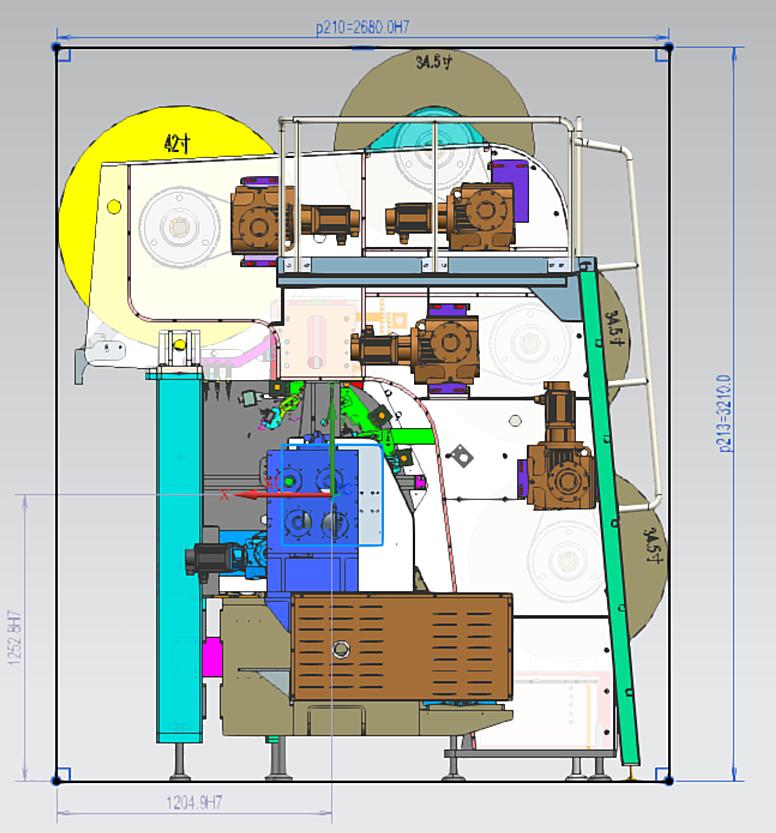

1) Core Mechanical Platform

Weft-Insertion System: A yarn-laying carriage with 24 ends lets you add in-plane stability, tune elongation, and control drape. This is valuable for performance apparel and technical layers.

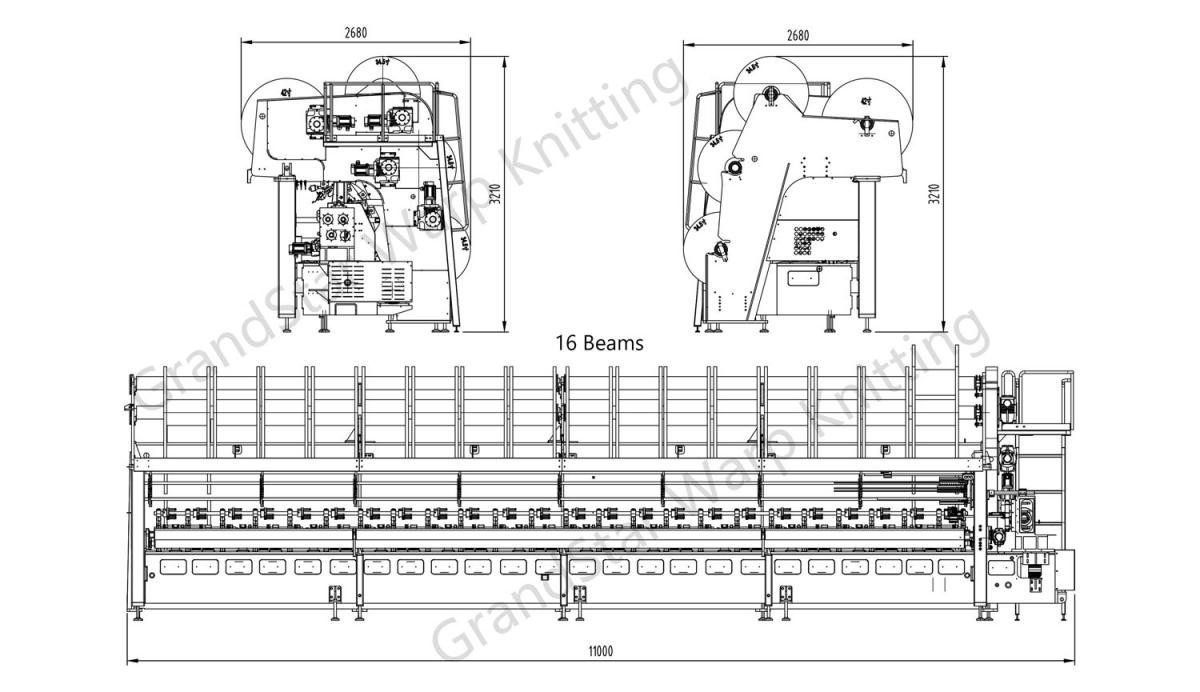

- Warp Beam Support: The standard free-standing setup is 2/3 × 812 mm (32″). Optional configurations include 2/3 × 1016 mm (40″) or 1 × 1016 mm (40″) + 3 × 812 mm (32″). Pick the mix that matches your yarn plan and floor layout.

- Guide Bars: Two guide bars with carbon-fiber-reinforced guide units reduce mass and damp vibration. This helps stitch accuracy at speed and lowers wear.

- Knitting Elements: The Individual Needle Bar, Slider Bar (½″ plate slider units), and Compound Sinker Bar collectively stabilize loop formation and fabric take-off.

2) Electronic Control & Monitoring

Our GrandStar® Command System is a single, clean interface for setup and oversight. Operators can adjust electronic functions, set tension targets, define pattern parameters, and tune take-up speeds with clarity. Alarms are readable. Diagnostics are direct. Training curves shorten, and shift-to-shift differences fade.

Monitoring is continuous. Laserstop enables precise, immediate stopping when a fault appears. The Integrated Camera confirms what happened, so the fix is targeted. Teams spend less time hunting and more time producing saleable fabric.

- Pattern Drive: The standard N-Drive includes three pattern discs plus integrated tempi change gear for reliable patterning.

- Optional EL-Drive: Add three electronically controlled motors to shog all guide bars up to 50 mm (or 80 mm with the extended option). Complex designs become a parameter change instead of a mechanical project.

3) Materials Handling, Power, And Thermal Control

- Yarn Let-Off: Each warp beam position uses an electronic let-off drive for consistent tension and repeatable thread feed.

- Fabric Take-Up: An electronically regulated, geared motor drives four rollers for smooth, accurate handling- especially helpful for delicate articles.

- Batching Device: A separate, floor-standing cloth rolling unit organizes rolls for finishing and transport.

- Electrical: 380 V ±10% three-phase supply with robust wiring and a speed-regulated main drive to keep delivery steady under load changes.

- Oil Supply: An oil/water heat exchanger stabilizes temperature, supports lubrication health, and extends component life.

In short, this is a Tricot Knitting Machine For Fabric that balances mechanical stiffness with smart electronics, so small issues never become big losses.

Service, Applications, And The Next Step

A strong machine needs stronger support. Hardware is only half the story; the rest is training, local help, and planned visits that keep performance predictable.

1) Training & Local Support You Can Plan Around

- Installation & Training: On-site sessions, online guidance, and video tutorials help your crews adopt best practices quickly.

- Local Service: After-sales coverage spans Turkey, India, Vietnam, Indonesia, and the USA. If we do not have a local team in your area, we start with real-time online diagnostics and dispatch engineers when needed.

- Regular Visits: Our engineers visit every 1- 2 months to check performance, coach maintenance, and stabilize operations.

2) Where The Machine Pays Back

- High-Fashion Fabrics: Intricate patterns and controlled drape for gowns and premium garments.

- Sportswear & Performance Textiles: Stretchable, breathable constructions with tuned recovery and weight.

- Technical Textiles: Industrial fabrics, filtration media, and protective layers- an ideal fit for a warp knitting machine for technical textiles roadmap.

- Home Furnishings: Curtains, upholstery, and decorative fabrics with reliable hand and fall.

- Automotive Interiors: Seat covers, headliners, and trims that must be repeatable in texture and color.

If you have struggled with uneven fabric faces, stop-start cycles, or pattern limitations, this platform offers a direct path out. With weft insertion, carbon-fiber-reinforced guide units, electronic let-off, and the option for EL-Drive, you can shorten time to first-quality and expand your fabric menu without new headaches. Operators like the interface. Maintenance appreciates the access. Finance sees higher uptime and a better first-pass yield.

Final Words

Ready to see what a modern Tricot Knitting Machine For Fabric can do on your floor? Contact Grand Star Technology for a plant-specific configuration, a throughput model for your yarn mix, and a live demonstration of the GrandStar® Command System. Let’s turn variability into repeatability – and turn repeatability into margin.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.