What You Need to Know About Warp Knitting Accessory

Warp Knitting Accessory is the backbone of stable fabric quality and higher machine uptime – and it’s exactly where small upgrades deliver big gains. From needles to tensioners, every detail matters more than most realize. Why do some machines run smoothly while others stop again and again? The answer often hides in these tiny parts. Let’s uncover how the right accessories can change everything on your production line.

Why Warp Knitting Accessory Choices Matter

Warp knitting is a chain of micro-contacts: yarn meets ceramic, slides through eyelets, rides tensioners, crosses reeds, and is formed by compound needles before the fabric leaves the rollers. Any weak link adds friction, heat, vibration, or misalignment. The result is uneven tension, pattern drift, broken ends, and unplanned stops.

- Common Pain Points On The Shop Floor

Uncontrolled tension is the most expensive “invisible” defect. It quietly raises waste and slows speed. Static build-up during warping attracts dust and causes erratic drops. Low-grade ceramics groove and fuzz yarn. Older needle bars flex at speed, making stitches inconsistent. And heavy beams increase inertia, stretching yarn during acceleration and deceleration.

At Grand Star Technology, we tackle these with a system view. Electronic detection, precise mechanics, low-wear ceramics, and balanced beams work together. For example, a Yarn Drop Stop Detector paired with a Laser Stop Device prevents fabric damage the instant an end breaks. Ceramic Eyelet Plates and Porcelain Tubes reduce abrasion through smoother surfaces and clean geometry. A Warping Static Eliminator stabilizes the yarn path before defects appear. When these Warp Knitting Accessory elements are aligned, operators stop firefighting and start optimizing.

What Grand Star Technology Brings To Your Line

We supply the full Warp Knitting Accessory chain – from warping to knitting – engineered for repeatability and service life. Our Ceramic portfolio (Eyelet Collar – both slit and standard, Eyelet Fabric Collar, Porcelain Tube) is formulated for polish retention, so yarn slides with minimal heat and lint build-up. Mechanical Parts such as Bearing & Bushing sets, Ball Cages, Hanger Bars, Pattern Discs, and Beam Shaft Connectors hold alignment under load, reducing micro-vibration that shows up as streaks.

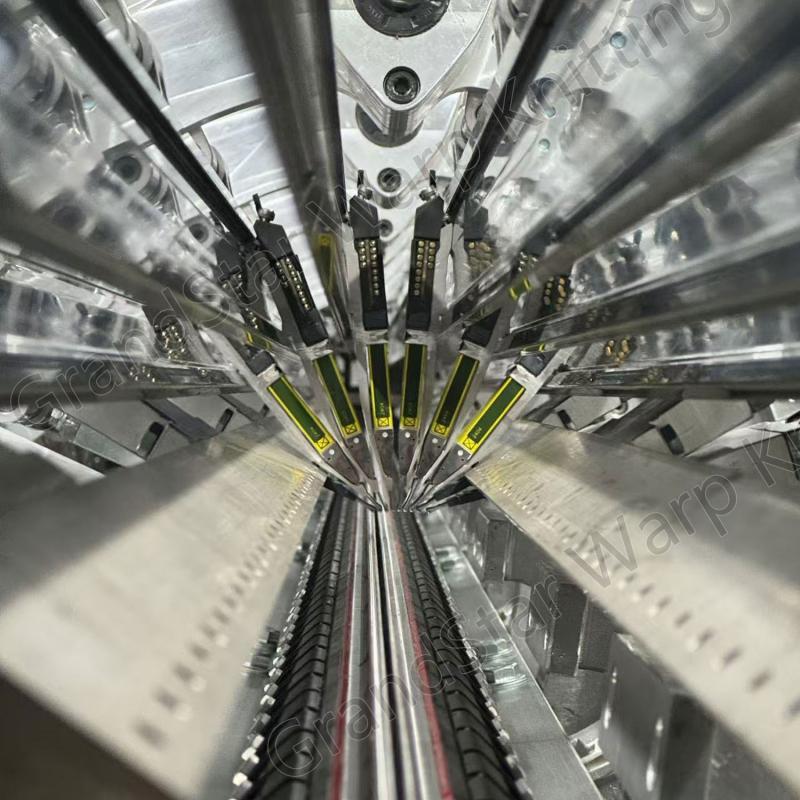

On the knitting side, precision Hook Needles, Guide Needles, Compound Needles, and Sinker systems (including laying-in and knock-over variants) ensure consistent loop formation. For patterning, our Piezo Jacquard for Warp Knitting supports a wide gauge window – from E12 to E34 – so you can cover fine to medium fabrics without swapping core electronics. Carbon-fiber Needle Bars lower mass and damp vibration at speed, protecting stitch geometry and reducing energy consumption. Reed Needles and Selvedge Spreader Devices finish the edges cleanly, minimizing post-process trimming.

- From Yarn Path To Pattern Control

Consider the yarn journey end-to-end. A Warping Creel feeds yarn to a controlled Yarn Tensioner, into Ceramic Eyelets, then across a Reed Needle set. A Beam Chuck and Beam Shaft Connector secure the warp on Forged or Cast Beams – each selected for stiffness vs. cost. Forged Beams deliver superior rigidity for high-speed sections; Cast Beams provide a value path where speeds are moderate. During production, a Laser Stop Device and Yarn Drop Stop Detector watch every end. If waste must be extracted, a Waste Yarn Winding Machine operating up to 1200 RPM clears the path quickly, cutting downtime between resets.

Electronics matter, but so does touch. The smoothness of Ceramic Eyelet Plates and the accuracy of Guide Needles for the Pattern Bar or piezo jacquard directly determine yarn path fidelity. When tension is even and friction is low, pattern clarity improves, and operators can push speeds safely.

✅ Key upgrades that pay back fast:

- Carbon-fiber Needle Bar to reduce mass and vibration.

- Ceramic Eyelet Plate + Porcelain Tube set to cut abrasion and fuzz.

- Warping Static Eliminator to stabilize ends before they reach the beam.

- Yarn Drop Stop Detector + Laser Stop Device to limit off-quality meters.

- Forged Beam where top stiffness is required; Cast Beam for cost-optimized lines.

How To Start Upgrading, Fast

You don’t need a full rebuild to see results. Target the few Warp Knitting Accessory points that control your highest losses: tension stability, static, and loop formation. Grand Star Technology can map defects to root causes along the yarn path and prioritize the upgrades that change your daily reality.

- A Simple Checklist

✅ Tension & Static

- Add a Yarn Tensioner with smooth ceramic pathing on critical positions.

- Install a Warping Static Eliminator on creel exits to reduce dust attraction and end drops.

✅ Forming & Pattern Fidelity

- Upgrade to Compound Needle and Sinker sets matched to fiber type.

- Use Guide Needles for piezo jacquard within the E12–E34 gauge window to protect clarity on fine work.

✅ Stops & Recovery

- Pair Yarn Drop Stop Detector with a Laser Stop Device for instant protection.

- Keep a Waste Yarn Winding Machine ready (up to 1200 RPM) to clear faults fast.

✅ Structure & Drive

- Choose Forged Beams for high-speed stability; use Beam Chuck and Beam Shaft Connector to lock alignment.

- Maintain Bearing & Bushing sets and Ball Cages to control micro-play that becomes visible as streaks.

Most plants see fewer yarn breaks, steadier selvedges, and cleaner patterns when ceramics and detection are modernized first. Next, structural parts (beams, needle bars) unlock speed without sacrificing quality. Finally, fine-tune with reeds, spreaders, and pattern accessories to lift first-quality yield.

Final Words

Ready to remove the hidden losses in your warp line? Contact Grand Star Technology for a quick, no-pressure audit of your Warp Knitting Accessory setup. We’ll review your yarn path, check beam and bar rigidity, and recommend a focused upgrade plan – ceramics, detection, pattern, and mechanics – so you hit higher speeds, cleaner fabric, and longer maintenance intervals. Let’s turn every rotation into profit.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.