What Quality Control Data Can an Advanced Warp Knitting Machine Save?

Warp Knitting Machine performance starts with the quality data you capture in warp preparation.

The fabric your customers see begins long before knitting. It starts at the beam. At Grand Star Technology, we build advanced direct warpers for filament yarn that record the right process data at the right time. This data makes each beam predictable, repeatable, and ready for any Warp Knitting Machine on your floor. Below, we explain what quality control data our system saves, why it matters, and how you can turn it into better fabric with fewer stops.

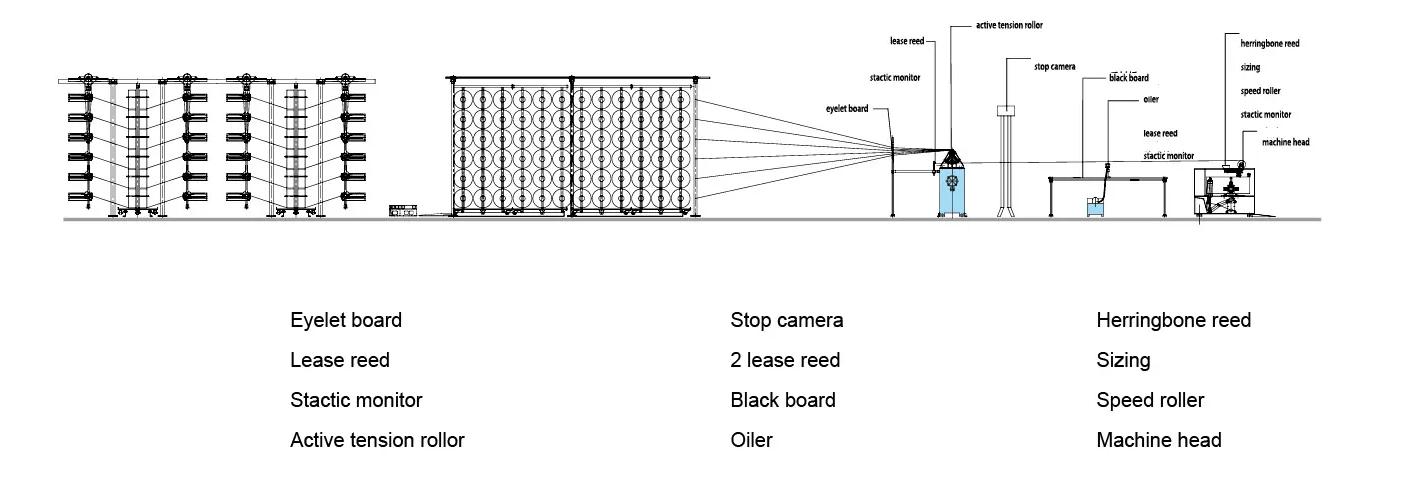

Why Data Matters in Warp Preparation for Warp Knitting Machines

In warp knitting, the beam is your foundation. If warp tension, length, and density drift during warping, those errors move straight into knitting. The result can be bar marks, loop defects, fabric skew, and wasted time. By saving accurate process data during warping, you can control variation at the source. You also gain full traceability for each beam. When a lot runs well, you can repeat its settings. When an issue appears, you can find and fix the root cause without guesswork.

The Core Quality Control Data We Save

Our advanced warping technology captures setpoints and actual values in real time. The system stores the data with each beam record for easy retrieval.

- Tension assurance: Automatic control archives set vs. actual tension over time, allowing you to confirm balanced warp loading and spot variance early.

- Motion profile logging: Speeds to 1000 m/min with acceleration/deceleration ramps are captured so you can confirm compliant transitions and protect fine filaments from shock.

- Exact stop location logging: Intelligent brake sync documents every stop and checks restart accuracy, avoiding length deviation and pattern misregistration.

- Beam growth and density monitoring: Stored circumference growth profiles and density trends help ensure consistent beam build and hardness.

- Last-9-Meter Control Records: The intelligent yarn storage system logs back-winding and handling for the final 9 meters of the warp sheet, so the most critical end segment stays under tight control.

- Yarn Break And End-Count Events: Camera-based end break detection (Camscan) records breaks, positions, and time stamps. You can link events to tension or speed changes and reduce repeat faults.

- Lubrication And Wrapping Settings: Infinitely variable oil coating and levelling roller wrap angle settings are saved with the beam file, preserving surface finish and filament integrity.

- Front Reed Traverse Data: Vertical and horizontal reed movements are recorded, supporting precise sheet alignment and reproducible cone-to-beam transitions.

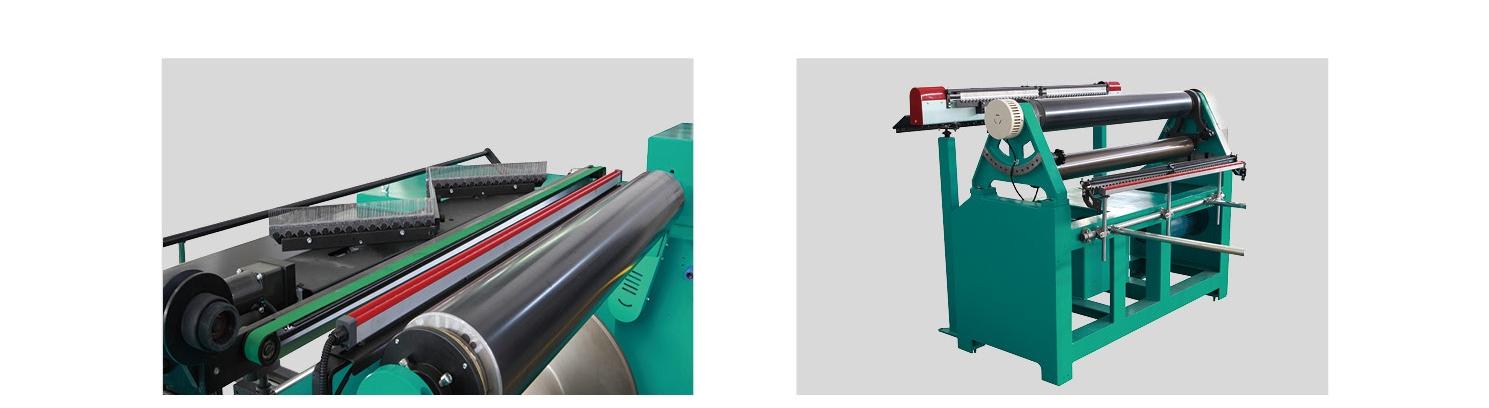

How Our Direct Warper for Filament Yarn Captures Accuracy

The best data is only useful if the process behind it is stable. We design for both.

- Our automatic tension regulation keeps yarn load steady even as package diameters change. This gives a clean, even sheet for consistent knitting.

- Precise brake synchronization delivers exact stop and restart, so length control remains intact across the entire run.

- Beam circumference control tracks build in real time. The result is uniform layer density and reliable beam hardness, supported by an optional pressure roller when higher hardness is required.

- For sensitive filaments, the lubrication system applies just the oil you specify, no more and no less, protecting yarn surfaces and reducing abrasion in knitting.

- The levelling roller’s adjustable wrap angle and the flexible front reed movement let you tune sheet geometry for different yarn types without trial and error. Every adjustment is recorded. Every outcome is traceable.

Turning Data into Action on the Shop Floor

Data should help crews move faster and make fewer mistakes. That is how we configure our interface and protocols.

- Setup Recall And Golden Recipes: Operators can load proven beam “recipes,” including tension targets, speed ramps, lubrication rates, and wrap angles. Changeovers become faster and safer.

- Real-Time Dashboards: A modern touchscreen presents key variables and alarms clearly. Crews see tension, speed, break counts, and layer density at a glance, reducing response time.

- Protocol Management For Audits: Integrated protocol management stores beam data with batch IDs and time stamps. Quality teams can pull records for customer audits or internal reviews in seconds.

- Exception Tags And Notes: Operators can add notes to events like a package change or yarn splice. That context speeds up root-cause analysis later.

What This Means for Your Warp Knitting Machine

When the beam is right, knitting flows. Stable tension profiles reduce guide wear and stop frequency on your Warp Knitting Machine.

- Exact stop locations and consistent beam build help keep stitch formation uniform and prevent pattern drift.

- Saved lubrication and wrap settings preserve yarn surface quality, which lowers fluff and dust load around the knitting zone.

- With warping speeds up to 1000 m/min, you meet delivery targets without sacrificing control.

- Because the last 9 meters are managed and documented, quality remains strong to the very end of the beam, where many knitting defects usually start.

- For mills running high-tenacity yarns, our device compatibility and controlled oiling protect strength while keeping friction in check. The result is fewer fabric faults, shorter setup times, and more predictable output day after day.

The Human Factor: Ergonomics, Safety, and Fewer Errors

Quality control is also about people. An optimized ergonomic design reduces fatigue, so operators keep attention on the process.

- The touchscreen interface uses clear menus and guided steps to cut input errors.

- Camera-based break detection minimizes manual checking and speeds up repairs.

- By combining human-centric design with stored process data, your team can sustain consistent quality across shifts and crews.

- New staff can follow saved recipes. Experienced technicians can refine them and push performance further, with every change logged for learning and reuse.

Start Your Data-Driven Warping With Grand Star Technology

Grand Star Technology helps you turn process data into fabric quality. Our direct warper for filament yarn combines intelligent control, precise mechanics, and comprehensive beam data saving to give your Warp Knitting Machine the best possible start. If you want to cut defects, stabilize throughput, and prove quality with records, we can help.

Call to Action:

- Request a live demo and see real-time tension and beam build data on your own yarns.

- Book a warp preparation audit and receive a practical data checklist for your next beam.

- Talk to our engineers about high-tenacity applications and lubrication control.

Contact us today to explore how our warping solutions can upgrade your quality control and your bottom line.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.