Guide to Choosing Warp Knitting Machine Accessories

When aiming to boost performance in textile manufacturing, selecting the right warp knitting machine accessory is more than just a technical choice – it’s a critical investment in quality, productivity, and machine longevity. Every accessory, no matter how small, plays a role in the overall efficiency of your warp knitting operation. From improving fabric consistency to reducing machine downtime, the right components make a measurable difference.

At Grand Star, we understand that no two production lines are the same. With over a decade of experience in the warp knitting industry, we’ve helped clients across the globe upgrade their machines with precision-fit accessories tailored to specific fabrics, machine types, and production goals.

This guide is designed to help you confidently select the most suitable warp knitting machine accessories for your needs. Whether you’re producing delicate lace or heavy-duty technical textiles, we’ll walk you through the key factors to consider – from machine compatibility and fabric type to performance demands and innovation options.

Why the Right Accessories Matter

Every component in a warp knitting machine plays a specific role. Even the smallest accessory can impact fabric quality, speed, and energy efficiency. That’s why choosing the right parts isn’t a luxury – it’s a strategic decision.

Key Benefits of Choosing the Right Accessories

✅ Better Fabric Consistency – Minimize defects and ensure uniform tension.

✅ Extended Machine Lifespan – Reduce wear and tear with precision-engineered parts.

✅ Faster Production Cycles – Operate at optimal speeds with minimal breakdowns.

✅ Lower Maintenance Costs – High-quality parts mean fewer replacements and repairs.

(Grand Star Needle Bar (Carbon-Fiber))

Categories of Warp Knitting Machine Accessories

To help you choose the best fit, here’s a breakdown of key warp knitting machine accessory categories we offer at Grand Star:

1. Mechanical Parts

Essential for structural performance and smooth machine operation.

• Bearing and Bushing

• Ball Cage

• Beam Shaft Connector

• Hanger Bar

• Selvedge Spreader Device

• Push Rod

• Swivel Frame

• Waste Yarn Winding Machine

These components ensure machine stability and alignment – two crucial factors in high-speed production.

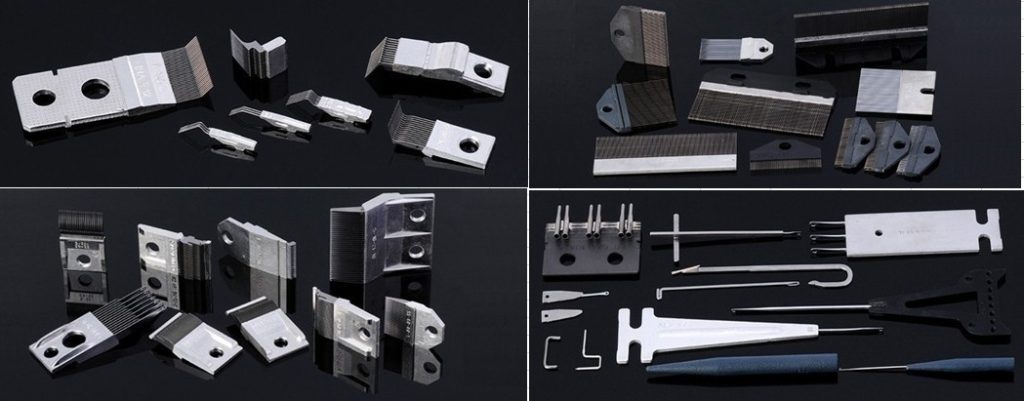

2. Knitting Needles & Needle Bars

The core of the knitting process.

• Latch Needle

• Sinker Needle

• Compound Needle

• Guide Needle

• Needle Bar (Carbon-Fiber & Standard)

Our carbon-fiber needle bars are lightweight, durable, and optimized for high-precision applications.

3. Warping Accessories

These components set the foundation for quality warp feeding.

• Warping Creel

• Warping Static Eliminator

• Beam Chuck

• Yarn Drop Stop Detector

• Guide Needle for Warping Machine

Proper warping setup ensures stable yarn delivery, minimizing snags and tension inconsistency.

4. Ceramic & Eyelet Components

Designed to reduce friction and static electricity.

• Ceramic Eyelet Plate

• Porcelain Tube

• Collar with Slit

• Ceramic Yarn Guides

These accessories support smooth yarn flow and reduce breakage, especially at high speeds.

(Grand Star Laser Stop Device for Warp Knitting)

How to Choose the Right Warp Knitting Machine Accessory

Selecting the right warp knitting machine accessory is a key step in maintaining efficient, high-quality textile production. Whether you’re working with lace, sportswear, or industrial fabrics, the right components make all the difference in performance, durability, and output. Here’s how to choose wisely.

1. Know Your Machine Type

Not all warp knitting machines operate the same way. Tricot, raschel, and stitch bonding machines each have distinct mechanisms – and therefore require specific accessories. Using an incompatible part may not only reduce efficiency but could also damage your equipment.

✔ Tip: Always check your machine’s manual or consult your technician before ordering accessories. Understanding your machine’s technical needs helps avoid costly mismatches.

2. Consider Your Fabric Requirements

The type of fabric you’re producing directly impacts the choice of accessories. Different materials require varying levels of tension control, precision, and delicacy.

✔ For delicate or lightweight fabrics (like lace or sheer materials):

Use fine guide needles, anti-static ceramic components, and smooth eyelets to prevent snags and breakage.

✔ For heavy-duty or technical textiles (such as automotive or industrial fabrics):

Opt for reinforced latch needles, robust bearings, and heavy-duty tensioners designed to handle strong yarns at high speeds.

Understanding your end product helps you match accessories that deliver both performance and protection for your yarn.

3. Evaluate Your Production Priorities

Every knitting operation has different goals – some focus on speed, others on consistency or reduced downtime. Before selecting accessories, ask:

• Do I need higher operating speeds?

• Am I facing yarn tension or breakage issues?

• Do I want longer maintenance cycles?

If speed is the priority, accessories like carbon-fiber needle bars or precision guide needles will help optimize motion and reduce machine wear. If consistency is key, focus on tension control accessories and advanced sensors.

Spotlight on Grand Star Innovation

At Grand Star, innovation is at the core of everything we do. Beyond supplying standard warp knitting machine accessories, we continuously develop advanced solutions tailored for modern textile challenges. Our goal is to help manufacturers boost efficiency, reduce waste, and stay ahead of the competition.

✅ Piezo Jacquard Systems – Deliver ultra-precise pattern control, allowing complex fabric designs with minimal signal interference. Ideal for high-speed and fine-pattern applications.

✅ Laser Stop Devices – Monitor yarn in real-time and immediately stop the machine when a break or fault is detected. This minimizes fabric waste and protects valuable yarn.

✅ Carbon-Fiber Needle Bars – Engineered for strength and agility, these bars are lightweight yet incredibly durable. They reduce vibration and wear, making them perfect for high-speed production lines.

These innovative accessories are built not just to perform – but to transform. Whether you’re producing fashion fabrics, technical textiles, or industrial materials, Grand Star’s cutting-edge components ensure your operations remain reliable, productive, and future-ready.

(Grand Star Piezo Jacquard For Warp Knitting)

Maintain for Maximum Performance

Even the best accessories need proper maintenance to last.

- Clean ceramic and tension parts regularly to prevent residue buildup.

- Inspect needle bars weekly to ensure they remain aligned.

- Lubricate moving parts with the correct oil to reduce friction.

- Replace bearings and bushings before they cause machine instability.

Good care not only extends accessory lifespan but also protects your overall machinery investment.

Conclusion: Ready to Upgrade Your Accessories?

Whether you’re building a new line or optimizing your existing one, Grand Star offers a complete range of high-performance warp knitting machine accessories to suit every application. With innovation at our core and customers at our heart, we’re here to help you succeed – one stitch at a time.

- Contact us today to learn more or get a personalized recommendation.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.