Warp Knitting Warping Machine: Advanced Tension Control for Flawless Beams

Warping Machine for Warp Knitting secures flawless beams by maintaining uniform, precise tension. Protected filaments and stable loads keep quality high on high-speed lines. It lifts yield and reduces waste. Yet many beams still show bands, soft cores, and frequent breaks. What determines tension uniformity in practice? The answer lies in design, drives, and automation. The decisive mechanisms will be detailed below.

Why Tension Control Makes or Breaks Warp Knitting

If tension drifts, everything else pays the price. Minute variations show up as barré, shade bands, uneven hand, and unstable beam hardness. On a high-speed warp knitting line, these small shifts multiply into frequent stops, slow ramp-ups, and excess waste. Conversely, when tension is locked in, beams run smoothly, needles stay calm, and fabric comes off the loom uniform and market-ready. That is why we treat tension control not as a feature, but as the core design principle of our Warping Machine for Warp Knitting.

What Consistent Tension Delivers on the Loom

- Lower stop rates and faster start-ups, especially on high-density styles

- Fewer yarn breaks, smoother selvages, and stable beam edges

- Better dye and finish uniformity, reducing rework and claims

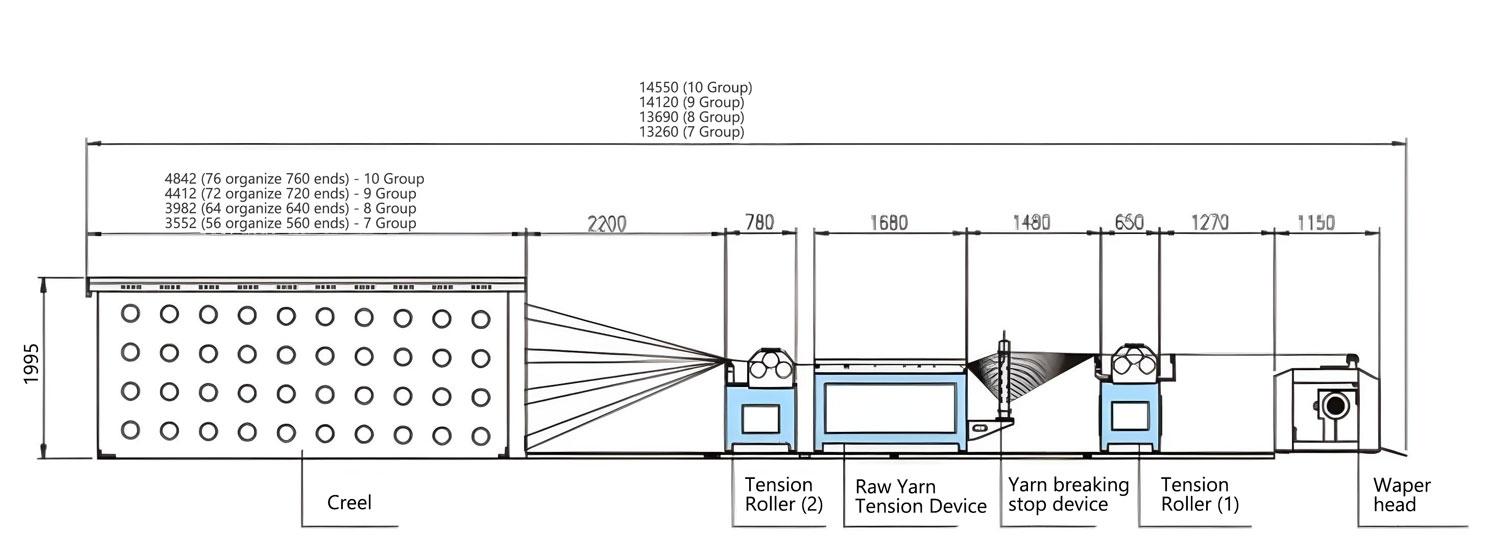

Meet Grand Star Technology‘s Warping Machine for Warp Knitting

Our Split Warping Machine is engineered for today’s fast-moving, high-spec warp knitting plants. It combines our patented mechanics with the latest international controls to deliver precision at speed. The system is multi-functional and handles diverse yarns with confidence, including chemical fiber filaments, low-stretch yarns, acrylic and cotton spun yarns, and single filament processing. Whether you are running nylon and polyester or specialty fibers, the machine maintains equal winding tension across all ends, so every beam leaves the floor ready for consistent knitting.

Built for Today’s Yarns

Modern fabrics are finer, stretchier, and more complex. That is why we equip each creel with a high-precision individual electric tension motor and pair it with a specialized tension roller system. This combination allows you to dial in the right behavior for superfine filaments, high-stretch deniers, or blended spun yarns without compromising beam build. The result is a Warping Machine for Warp Knitting that keeps pace with product development while protecting day-to-day efficiency.

Mother Yarn Splitting + Direct Warping: One Pass, Big Savings

Why run two processes when one will do the job better? Our machine splits mother yarn and winds it directly onto the warp beam in a single, streamlined pass. This approach removes handoffs that create variation and saves both time and floor space.

- Eliminate separate splitting and warping steps to shorten lead time

- Reduce handling and intermediate storage to stabilize tension history

- Lower labor and overhead with a compact, integrated line

- Cut quality risk by keeping yarns in a controlled path from split to beam

Customers see the impact quickly. With fewer transfers, end-to-end tension is more uniform, and operators manage one workflow instead of two. That clarity shows up on your beams and in your schedules.

Advanced Tension Control for Flawless Beams

Tension is only as good as the control loop behind it. Our specialized roller system smooths transient spikes, while the individual electric creel motors fine-tune each end. This ensures equal winding tension across all yarns, even when bobbin diameters vary or environmental conditions change. The closed-loop response is fast and gentle, so you avoid overcorrection that can damage delicate filaments.

In practice, that translates into fewer breaks, stable beam density across layers, and consistent roll hardness from flange to flange. When beams are this uniform, warp knitting runs in the sweet spot: needles stay clean, knockovers are dependable, and fabric appearance is repeatable from lot to lot. For plants chasing high-speed, high-density output, this level of control is the difference between fighting the line and flowing through the plan.

Automation That Protects Your Margins

We pair mechanics with smart control. A customized next-generation PLC touchscreen monitors and adjusts tension automatically, guiding the process with clear setpoints and alarms. The system is built to:

- Achieve 100% utilization of cheese yarns with little to no waste

- Optimize yarn consumption to reduce material loss at changeover

- Minimize manual intervention, freeing operators for higher-value tasks

These are hard savings that show up in your cost per meter and in your uptime. Near-zero end waste at the cheese and optimized beam fill add capacity you can sell. Stable automation also helps new operators succeed faster, while experienced teams can push higher speeds without compromising quality. Data visibility supports consistent practices across shifts and lots, which is vital when you are running different yarn families through the same line.

Your Best Choice for High-Speed Warp Knitting

Manufacturers today need flexibility, speed, and reliability in one package. Our Warping Machine for Warp Knitting delivers that by tying precision engineering to production realities. It handles chemical filaments, low-stretch yarns, acrylic and cotton spun yarns, and single filaments with equal confidence. It streamlines mother yarn splitting and direct warping to save time and space. It locks in tension with specialized rollers and individual electric creel motors. And it automates decisions with a PLC interface that helps you use every meter of yarn.

At Grand Star Technology, we measure success beam by beam: fewer breaks, cleaner fabric, steadier schedules, and lower waste. If you are investing to improve fabric quality, stabilize high-speed runs, or expand into fine and high-stretch styles, our solution is designed to give you a fast return and a long runway.

Call to Action: See It on Your Yarn

Bring your yarns and targets to us. We will run a beam trial, share tension and waste data, and map the gains to your product mix. Contact Grand Star Technology to request a demo, send your specifications, or schedule a plant-level discussion. Let’s build flawless beams – and stronger margins – together.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.