The Economic Edge of High-Quality Tricot Machines

In modern textile industry, manufacturers are under constant pressure to deliver superior quality, efficiency, and flexibility. One of the most critical assets in achieving this is high-quality tricot machines. As a leading manufacturer, we at Grand Star are proud to design and build machines that not only meet but exceed industry expectations. With our advanced engineering and customer-centric designs, our machines help clients reduce costs, increase productivity, and stay ahead in their markets.

Why High-Quality Tricot Machines Matter for ROI

1) Precision and Flexibility Driving Savings

When it comes to textile production, precision matters. High-quality tricot machines are engineered with tight tolerances and advanced control systems that minimize waste and reduce the need for costly rework. By maintaining uniform stitch density and exact gauge settings – even across varying yarn types – these machines help you:

• Eliminate fabric defects before they occur

• Reduce yarn consumption through optimized tension control

• Shorten production runs with faster setup times

Over time, the cumulative savings from fewer stoppages, less material waste, and lower labor costs can exceed the initial investment by several multiples.

2) Versatile Fabric Production and Market Reach

One of the greatest economic advantages of High-quality tricot machines is their versatility. Whether you’re producing lightweight mosquito nets or high-end automotive textiles, modern tricot knitting technology adapts to diverse applications without requiring separate platforms for each product line. This flexibility allows you to:

• Respond quickly to changing market trends

• Consolidate equipment needs to free up floor space

• Negotiate better yarn pricing by pooling orders

By leveraging a single, adaptable machine for multiple fabric types, you streamline operations and unlock new revenue streams across apparel, home furnishings, technical textiles, and more.

Key Features of Grand Star‘s Tricot Machines

At Grand Star, we design every tricot knitting machine with an unwavering commitment to quality, durability, and user-friendly operation. Here are some of the standout features that set our equipment apart:

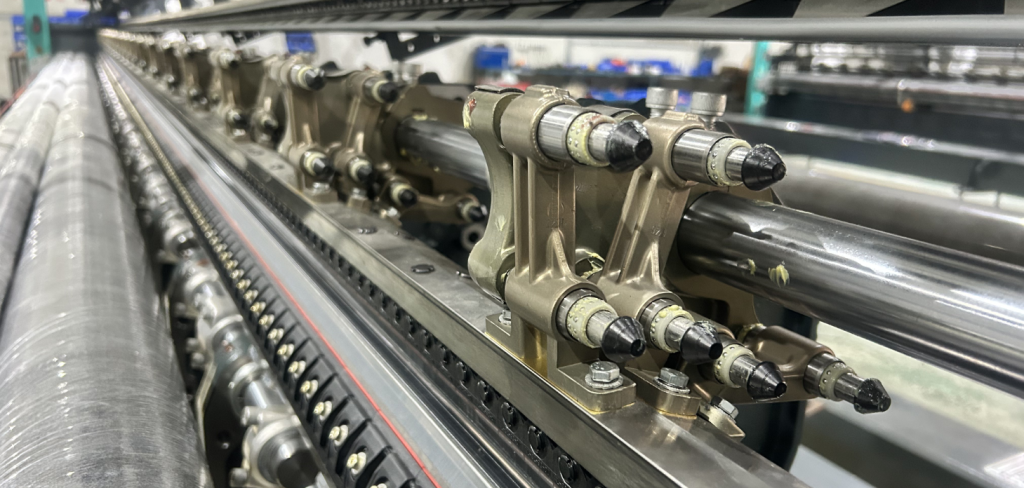

1) Flexible Guide Bar Layouts

Our models offer between two and four guide bars, each crafted from carbon-fiber-reinforced materials for strength and minimal wear. More guide bars mean greater pattern complexity and finer fabric textures – without compromising machine speed or reliability.

2) Precision Engineering and Quality Control

Integrated Laserstop and real-time camera inspection systems detect faults instantly, so you never have to compromise on quality. Electronic fabric take-up and yarn let-off drives maintain consistent tension throughout production, ensuring every yard of fabric meets your specifications.

Industry Applications and Profit Opportunities

High-quality tricot machines aren’t one-trick ponies – they excel across a wide range of sectors. Below, we highlight key applications and associated profit advantages for each guide-bar configuration:

1) Tricot Machines with 2 Guide Bars

• Mosquito Nets: Lightweight, tear-resistant fabrics with minimal material use

• Mattresses & Bedding: Breathable, durable textiles that command premium retail prices

• Embroidery Bases & Tulle: Fine netting ideal for high-margin decorative applications

• Coating Substrates: Uniform, strong surfaces perfect for industrial laminates

• Advertising Media: Stable backdrops for banners and signage

2) Tricot Machines with 3 Guide Bars

• Automotive Textiles: Premium seat covers and headliners with tailored performance specs

• Upholstery Fabrics: Durable, aesthetic weaves that elevate furniture lines

• Sportswear: Breathable, stretchable knits commanding higher price points in activewear

• Toy Plush Materials: High-pile, soft fabrics for lucrative stuffed-toy markets

• Outerwear & Lingerie: Lightweight, form-fitting knits popular in fashion and intimate apparel

3) Tricot Machines with 4 Guide Bars

• Premium Upholstery: Plush, textured fabrics for high-end furniture and automotive interiors

• Footwear Textiles: Breathable, flexible knits increasingly in demand for performance shoes

• Cleaning & Wiping Textiles: High-absorbency fabrics used in industrial and household products

• Pile Fabrics: Luxurious, textured materials commanding top dollar in home decor and apparel

By matching machine capabilities to specific market segments, you maximize yield on each production hour and position your business for premium pricing.

The Grand Star Engineering Advantage

At Grand Star, precision and innovation go hand in hand. Our high-quality tricot machines are designed not only to meet modern textile demands but to exceed expectations with every meter of fabric produced. From the finest technical features to intuitive operation and sustainable engineering, we’ve built a system that enhances performance at every level.

1) Precision at Every Step

Each Grand Star machine is crafted for accuracy, ensuring flawless results regardless of fabric density. Whether you’re producing airy mesh or tightly knit textiles, our machines guarantee uniform stitch formation with high repeatability.

We integrate:

✅ Compound needle bars for accurate loop formation

✅ Sinker and slider systems that maintain balanced tension

✅ Adjustable gauge options (E28, E32) to suit varied designs

✅ Working widths up to 8636 mm for increased productivity

This ensures that every yard of fabric meets quality standards, minimizing waste and rework.

2) Seamless Operation and Control

With the GrandStar® Command System, managing complex textile production becomes simple. Our user-friendly interface allows operators to take full control of machine settings, monitor progress, and detect issues early – keeping downtime to a minimum.

Key benefits:

✅ Intuitive touchscreen HMI

✅ Real-time production and fault tracking

✅ Access to pattern configuration and machine diagnostics

✅ Laserstop and integrated camera for instant defect alerts

Operators stay in control, maintaining high-speed performance with ease.

3) Efficient and Eco-Friendly Systems

Efficiency doesn’t stop at output. Our machines are designed with energy-conscious systems that reduce costs and environmental impact – without compromising production speed.

Sustainable highlights:

✅ Speed-regulated drive for energy savings

✅ Oil/water heat exchanger for optimal thermal regulation

✅ Electronically controlled yarn let-off to reduce material waste

With Grand Star, you get cleaner, smarter, and more cost-effective production – all in one powerful platform.

Economic Benefits of High-Quality Tricot Machines

Investing in high-quality tricot machines isn’t just a technological upgrade – it’s a strategic financial decision.

Here’s how our machines give you an edge:

• Reduced waste due to real-time quality control

• Faster production cycles with stable fabric take-up and let-off systems

• Lower maintenance costs due to durable carbon-fiber components

• Versatility across markets, from automotive to fashion

• Consistent product quality, boosting brand reputation and customer satisfaction

Over time, these advantages translate to significantly higher returns on investment.

Built for the Future of Textile Manufacturing

As textile trends evolve, adaptability becomes essential. Whether you need to produce breathable sportswear, plush upholstery, or technical fabrics, our machines can be configured to match your goals.

Our tricot machines grow with your business by offering:

• Modular upgrades (pattern drive, guide bars, gauges)

• Compatibility with smart manufacturing systems

• Data integration for quality and production analysis

We’re not just delivering machines – we’re providing tools for long-term success.

Final Thoughts

High-quality tricot machines are no longer optional for serious textile manufacturers. They are a foundational asset in building efficient, scalable, and future-proof production. At Grand Star, we combine precision engineering with real-world functionality to ensure you get the most out of your investment. If you’re ready to transform your textile operations, let’s start with the right machine. Get in touch today to learn more about how our high-quality tricot machines can help you gain the economic edge you’ve been looking for.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.