Geo Textile Warp Knitting Machine Enhances Let-Off Control

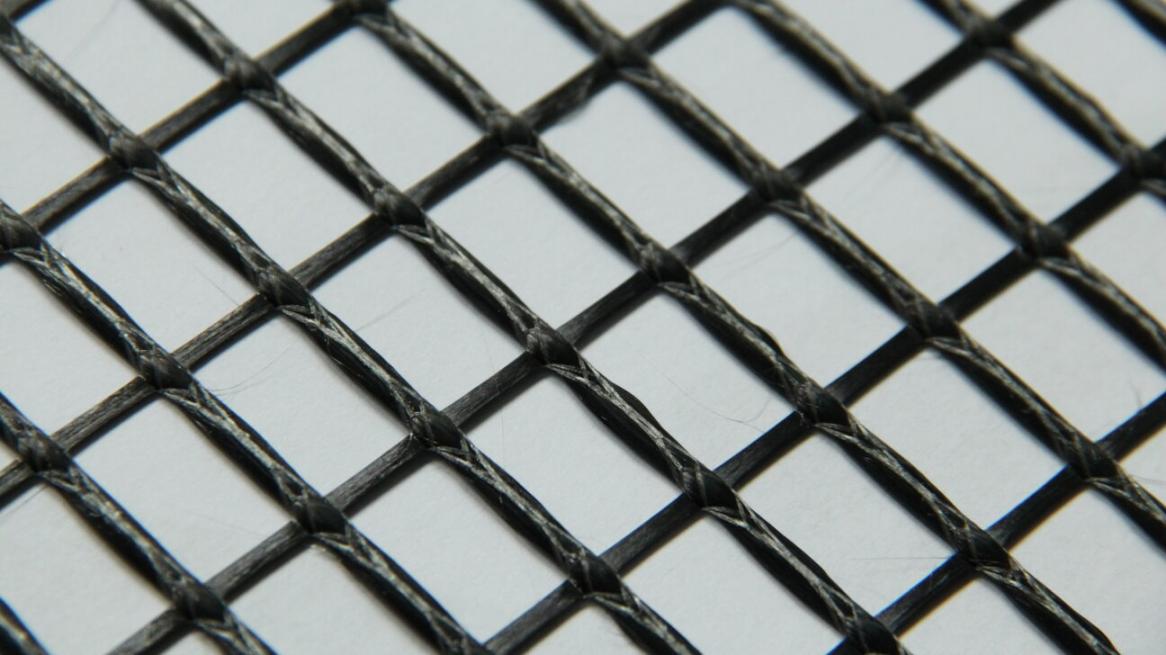

The demand for advanced geotextile solutions continues to rise as infrastructure and civil engineering projects expand worldwide. In this fast-moving landscape, the need for efficient, reliable, and smart machinery has never been more urgent. Among the technologies leading this charge is the Geo textile warp knitting machine, especially those equipped with high-precision yarn control systems.

At Grand Star, we don’t just build machines – we engineer solutions that solve real-world challenges in the textile industry. Over the years, we’ve worked closely with fabric manufacturers, field engineers, and plant operators to understand the pain points that slow production or compromise fabric consistency. The result? A Geo textile warp knitting machine that features not only advanced mechanics, but also electronically controlled let-off for unmatched precision.

Precision Let-Off

Let’s talk about yarn tension – an element often underestimated but absolutely critical in geotextile manufacturing. Whether you’re producing fabrics for road stabilization, erosion control, or drainage applications, maintaining consistent tension across every yarn strand is key to producing reliable, high-performance materials. And yet, many traditional machines struggle with this very issue, especially when dealing with wide-format fabrics or fine-gauge production.

That’s exactly why we developed our precision let-off system as a core feature in the Grand Star Geo textile warp knitting machine. Designed with practical manufacturing needs in mind, this system offers an electronically controlled yarn let-off drive for each warp beam position – up to four in total. Rather than relying on outdated mechanical tension controls, the machine uses a geared motor system that intelligently adjusts yarn feed in real-time.

This results in several key benefits:

✅Smooth, vibration-free yarn release that ensures fabric surfaces remain uniform and defect-free

✅Real-time tension correction, ideal for reactive adjustments during continuous production

✅Minimized yarn breakage, reducing both downtime and wasted material

✅Consistent tension even at high speeds, allowing producers to scale output without compromising quality

In practical terms, this isn’t just a technical upgrade – it’s a game changer. In a recent implementation with a Southeast Asian client producing 230″ wide geotextiles, switching to our Geo textile warp knitting machine with precision let-off led to a measurable reduction in yarn waste – less than their previous setup. Over time, those savings added up significantly, not just in raw material costs, but also in reduced rework and improved customer satisfaction.

The precision let-off system also plays a vital role when working with finer gauges like E18, where even slight variations in tension can compromise stitch formation or fabric integrity. By automatically regulating yarn feed according to production speed and material load, the machine gives operators peace of mind – no constant tension adjustments, no guesswork, just consistent performance. If you’re aiming to boost the efficiency and reliability of your geo textile line, this is the technology upgrade that delivers long-term value from day one.

Built for Versatility and Industrial Strength

While precision yarn let-off is a headline feature, it’s just one part of what makes this Geo textile warp knitting machine a solid investment. We’ve designed the platform to be highly flexible, offering working widths from 181″ up to 275″, with compound needle types and up to eight guide bars.

The knitting components include:

- Single-bar and comb bar configurations

- Slider bar for advanced fabric profiles

- Stitch comb bar for balanced tension transfer

- Full support for GB1 to GB4 stitch-forming

Internally, our machines are powered by the GrandStar COMMAND SYSTEM, a proprietary control suite that lets operators manage, modify, and fine-tune every electronic parameter – from pattern control to yarn motion. And thanks to Motion Control-regulated take-up systems, you get even fabric winding with minimal operator intervention.

Even the batching device, which handles the fabric roll-up, is floor-standing and built to handle the physical demands of geo fabric production. Whether you’re producing drainage layers, road reinforcement textiles, or erosion control fabrics, our machine delivers the output consistency your projects demand.

Designed for Real-World Manufacturing Conditions

At Grand Star, we understand that a machine is only as good as its ability to withstand tough working conditions. That’s why our Geo textile warp knitting machine is engineered for heavy-duty environments.

- Temperature range: 25℃± 6℃

- Humidity tolerance: 65% ± 10%

- Voltage: 380V ± 10% three-phase (global standard)

- Load: 25 kVA, with robust electrical infrastructure

We’ve also incorporated safety and monitoring features like Laserstop technology, which instantly halts operations in the event of a yarn break. The electronic pattern drive (EL) and anti-friction fabric take-up reduce wear and ensure long-term performance. All components, from motors to power cords, meet international standards – because we know reliability isn’t optional.

Our goal is simple: to build machines that keep working when others can‘t.

Why More Manufacturers Trust Grand Star

We’re not just a supplier – we’re a partner in your production goals. When customers choose Grand Star, they gain access to:

✅Tailored machine configurations based on your product line

✅Hands-on training and after-sales support

✅Continuous software and hardware upgrades

✅Proven results in real production environments

The Geo textile warp knitting machine is more than a tool – it’s a long-term production solution designed to give you speed, quality, and control. And with our growing network of clients across Asia, Europe, and the Middle East, we’ve seen firsthand how the right machine can drive exponential business growth.

Ready to modernize your geotextile production line?

Let’s talk. At Grand Star, we’re proud to power the next generation of smart manufacturing – one precision stitch at a time.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.