Warp Knitting Technology: Unlocking Value of Double Jacquard 6/2

Warp Knitting Technology is reshaping how mills deliver patterned, technical, and performance fabrics, and at Grand Star Technology we approach every machine from a maker’s point of view. Our Double Jacquard Raschel Fabric Machine 6/2 unites pattern freedom, structural stability, and efficient setup in one platform. Below, we explain why it matters to modern factories, what sits inside the machine, and how our service turns specifications into repeatable production results.

Why Warp Knitting Technology Matters

Product teams feel pressure on three fronts: variety, speed, and reliability. Brands expect richer designs without long lead times. Converters ask for quick changeovers and patterns that repeat cleanly across orders. Mill managers must deliver stable quality even as staffing and training windows tighten. Warp Knitting Technology directly addresses these realities with stable loops, high fabric integrity, and predictable run behavior.

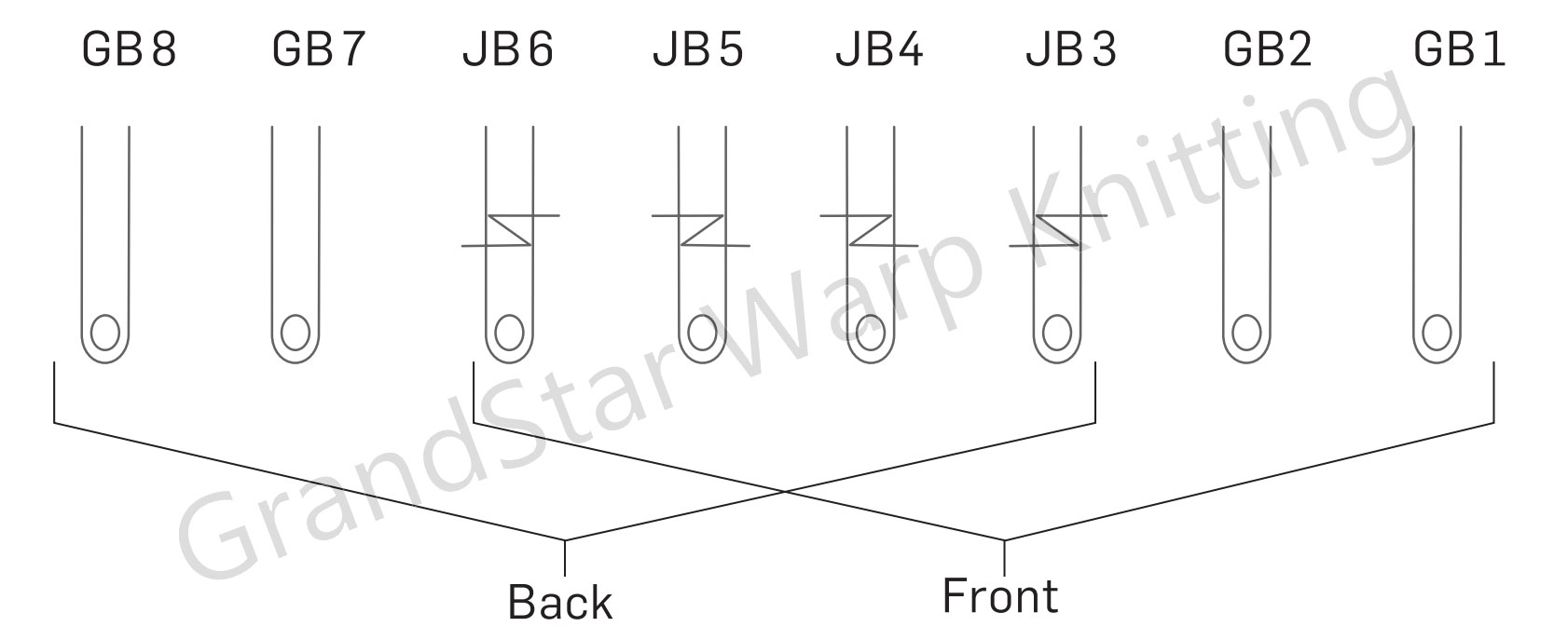

For us, the defining word is control. Control of pattern, control of yarn paths, and control of setup all shorten the path from first trial to signed-off production. The split piezo-jacquard guide bar gives designers the headroom to create detailed motifs while maintaining line stability. Two individual latch needle bars improve stitch accuracy and broaden the workable style range. And because stitch forming relies on GB3, GB4, JB5, and JB6 across both needle bars, fabric hand and edges remain consistent as you shift between apparel programs and technical contracts.

In practice, the Double Jacquard Raschel 6/2 delivers pattern richness on a stable base. It reduces rework, keeps the gauge aligned with the end use, and supports a wide portfolio – from lace and spacer fabrics to meshes for industrial and automotive uses, and technical textiles such as geotextiles or filtration layers. That combination protects margins and supports dependable delivery timelines.

Inside the Machine

- Working Width & Gauge Alignment

A working width of 3454 mm (136″) supports wide goods, efficient downstream handling, and less panel joining. Gauge options E18, E22, E24, and E28 let you dial stitch density to the application – from airy meshes to crisp jacquard surfaces – without sacrificing the loop stability that Warp Knitting Technology is known for.

- Knitting System & Bars for Precise Patterning

The knitting heart of the machine is designed to turn complex briefs into clean, repeatable output. Six ground guide bars create the base structure for intricate fabric formation. The piezo-jacquard guide bar, in split execution, enables rich, high-definition jacquard effects with controlled apertures. Stitch forming on GB3, GB4, JB5, and JB6 across both needle bars ensures precise loop geometry. Two knock-over comb bars and two stitch comb bars reinforce a clean knock-over and stable loop release, helping edges and lines stay tidy on longer runs.

- Control & Automation: From Screen to Shop Floor

GrandStar® Command System provides an intuitive operator interface for configuring, controlling, and adjusting electronic functions. Teams get up to speed faster, and changeovers feel consistent from shift to shift. The Electronic Guide Bar Drive EL lets all guide bars shog up to 150 mm, giving pattern engineers the reach they need for complex layouts while keeping motion precise and repeatable.

Fine tuning is straightforward. The knock-over comb bar distance is continuously adjustable from 2-12 mm, and the central trick plate allows distance readjustment for fine-grained fabric control. These settings help you hold hand, weight, and openness where you want them – without the trial-and-error that slows approvals.

- Warp Beam Capacity & Handling

For stable running and convenient loading, the machine supports six warp beams, each 812 mm (32″), with a free-standing design. That capacity suits multi-yarn constructions and staged colorways while keeping access clear for operators and maintenance teams. The result is simpler setups and fewer interruptions once production is underway.

Training, Service & Applications

A machine is only as strong as the service behind it. That is why installation and training are not afterthoughts but part of the value we deliver. Technical support sits at the core of our warp knitting program, and we offer comprehensive training in multiple formats – covering setup, pattern adjustments, preventive care, and day-to-day operating routines. Our after-sales service operates locally in Turkey, India, Vietnam, Indonesia, and the USA, with planned expansion to additional countries. Proximity shortens response times and builds operator confidence, especially during the first weeks on a new style.

Where does this platform excel? The Double Jacquard Raschel Fabric Machine 6/2 spans fashion, home, and technical categories, helping you scale what you already do well – or enter new segments that align with the strengths of Warp Knitting Technology:

✅Jacquard fabrics for garments and home textiles – clear motifs, defined lines, and repeatable hand.

✅Mesh and spacer fabrics for sportswear, automotive, and industrial uses – engineered openness with dependable rebound.

✅Technical textiles including geotextiles, filtration, and reinforced fabrics – stable structures to support function-first briefs.

✅Lace production for fashion and interior design – fine surfaces with consistent pattern fidelity.

If you are searching for a double jacquard raschel fabric machine 6/2 to broaden your program, or evaluating a warp knitting machine for technical textiles, the next step is a focused configuration review. We can map gauges, guide bar setups, and beam plans to your target fabrics, then outline a training path that brings your team to speed quickly.

Call to Action

Ready to turn specifications into production? Contact Grand Star Technology for a configuration review, training outline, or on-site demonstration plan tailored to your product mix. Let’s use Warp Knitting Technology – and the specific advantages of the Double Jacquard Raschel 6/2 – to deliver stable quality, faster approvals, and a broader fabric portfolio.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.