How High-Speed Tricot Machines with 4 Guide Bars for Sale Maximize Fabric Quality

Looking for a way to elevate your fabric production? High-speed Tricot Warp Knitting Machines for Sale are the solution you need. These machines, equipped with 4 guide bars, offer unmatched precision and efficiency in creating high-quality fabrics. Whether you’re in fashion, sportswear, or technical textiles, these advanced knitting machines can drastically improve your production process. But how exactly do they work, and what makes them so special? Let’s dive deeper into the features that set these machines apart and discover why they are a must-have for manufacturers.

Superior Fabric Quality with 4 Guide Bars

One of the key features that set High-speed Tricot Warp Knitting Machines for Sale apart is the incorporation of 4 guide bars. These bars work together to ensure that the fabric produced is of the highest quality, offering exceptional precision and smoothness.

The machine boasts an individual needle bar with compound needles and a slider bar with plate slider units, allowing for efficient fabric production. The sinker bar, equipped with compound sinker units, further ensures that the fabric’s structure remains intact throughout the knitting process.

This setup allows for:

- High-precision fabric production with minimal defects.

- Increased efficiency in fabric production, as the guide bars work together to create smooth and consistent fabric.

- Enhanced texture control, ensuring that the fabric feels soft and durable.

By using advanced knitting elements and guide units, manufacturers can achieve fabrics that are not only visually appealing but also meet the stringent standards required in fashion, sportswear, and technical textiles.

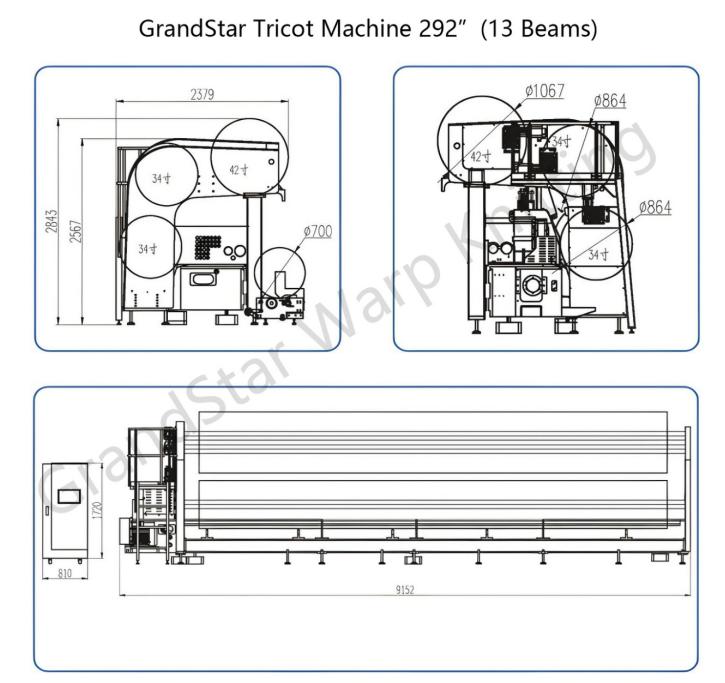

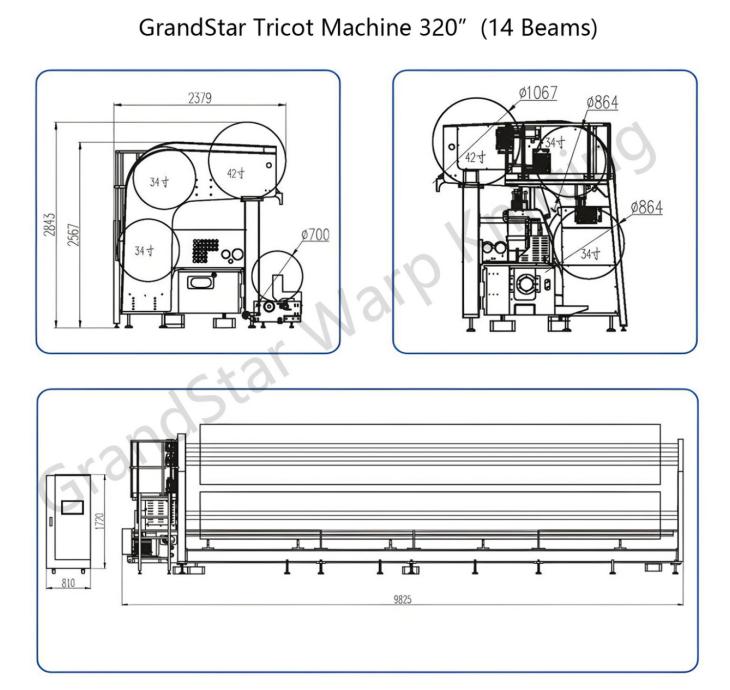

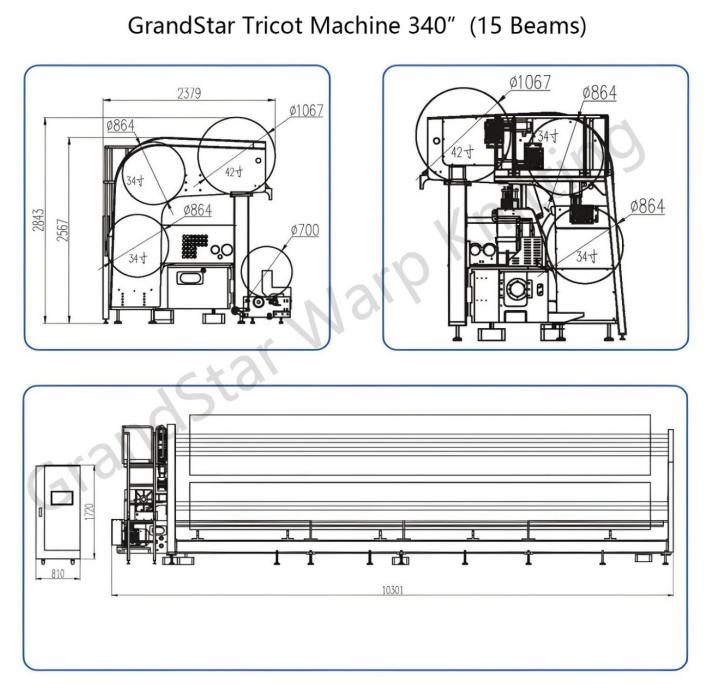

Flexibility and Efficiency: Warp Beam Support and Fabric Take-Up System

Another remarkable feature of these high-speed tricot machines is the Warp Beam Support. The machines are designed for flexibility, supporting multiple warp beam configurations. Whether you need to handle smaller beams for finer fabrics or larger beams for bulk production, this system can adapt to meet your needs. With the capacity to accommodate various sizes (up to 40 inches), you can ensure that your machine is capable of handling diverse production requirements.

Moreover, the Fabric Take-Up System is a game-changer when it comes to maintaining consistent fabric quality. Powered by a geared motor and regulated electronically, this system ensures uniform tension control through four rollers. As a result, the fabric take-up process is smoother, preventing issues such as fabric distortion or uneven tension.

This means:

- Flexibility in handling various warp beam sizes, allowing manufacturers to produce a wide range of fabric types.

- Consistent fabric quality due to precise tension control, reducing the risk of defects.

- Improved efficiency, as the fabric take-up system ensures the production process flows seamlessly without interruptions.

These features are crucial for manufacturers aiming to meet the ever-growing demands for high-quality, efficient fabric production.

Integrated Monitoring Systems: Reducing Waste and Maximizing Quality

In today’s fast-paced textile industry, quality control is more important than ever. With Integrated Monitoring Systems like Laserstop and real-time camera inspections, High-speed Tricot Warp Knitting Machines for Sale help minimize waste while ensuring that every piece of fabric meets the highest standards.

Laserstop technology automatically detects fabric defects, halting production immediately to prevent faulty goods from being produced. Additionally, the camera system provides continuous monitoring, offering a real-time view of fabric quality during production. This enables manufacturers to catch any issues early and resolve them before they become bigger problems.

By utilizing these systems, manufacturers can:

- Minimize fabric waste, reducing costs and environmental impact.

- Ensure top-notch quality with real-time defect detection and monitoring.

- Improve customer satisfaction, as only high-quality fabrics are delivered to the market.

This real-time quality control is a huge advantage for manufacturers who prioritize excellence in every batch of fabric they produce.

- Why Choose Grand Star’s High-Speed Tricot Machines?

At Grand Star, we believe that investment in the right machinery can significantly impact your production quality and efficiency. Our High-speed Tricot Warp Knitting Machines for Sale are built with cutting-edge technology and offer unmatched performance. Whether you’re producing fabrics for fashion, sportswear, or medical applications, our machines are designed to meet the specific needs of your business.

We provide comprehensive training and after-sales services to ensure that you get the most out of your investment. Our training options include on-site sessions in over 20 countries, with dedicated local teams in key regions such as Turkey, India, and the USA. And with our global after-sales support, you can rest assured that help is always available when you need it.

Ready to Take Your Fabric Production to the Next Level?

If you’re looking to improve the quality and efficiency of your fabric production, Grand Star’s High-speed Tricot Warp Knitting Machines for Sale offer the perfect solution. Our machines are engineered to provide high-quality results while minimizing waste and maximizing efficiency. Contact us today to learn more about how our machines can help your business grow and stay competitive in the ever-evolving textile industry. Invest in Grand Star’s cutting-edge technology for superior fabric production!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.