How Shogging Creates Textured Patterns? 2026 Guide From a HKS Machine Manufacturer

As a HKS Machine Manufacturer, Grand Star Technology reveals how shogging turns precise guide bar motion into rich fabric textures. This is a controlled art of lapping, tension, and monitoring. What hidden parameters shape the surface, and how can they cut cost while lifting quality? The answers lie in motion control, advanced needles, and real-time vision.

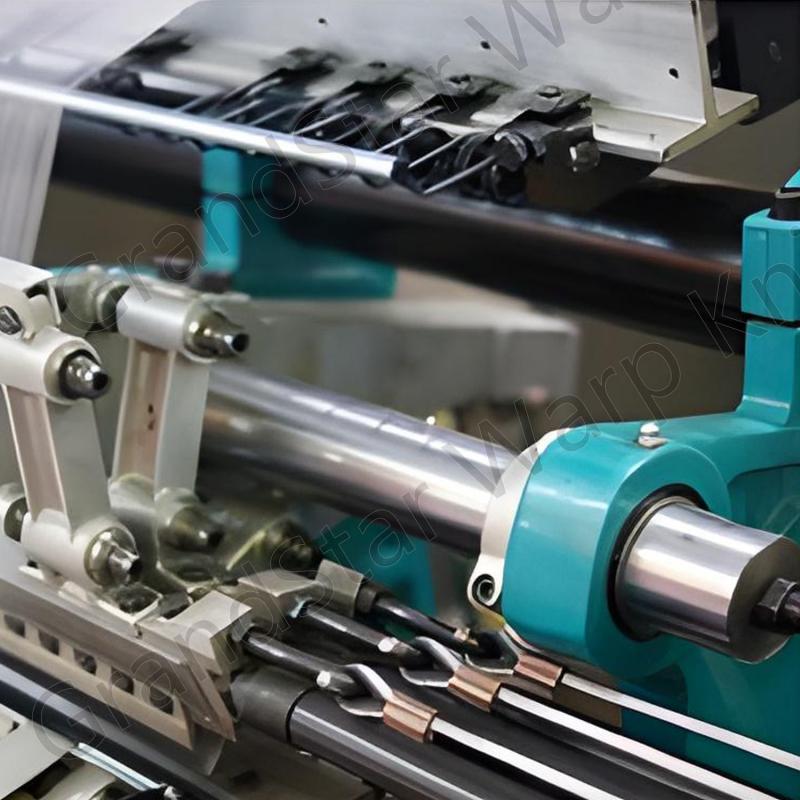

Shogging Basics From a HKS Machine Manufacturer

Shogging is the controlled side-to-side movement of guide bars across the needle bed. In tricot knitting, this movement defines how each yarn wraps around the needles and how loops overlap. When you change the shog distance, timing, and sequence, you change the fabric surface. You get waves, micro-ribs, mesh-like openness, or subtle mock-jacquard effects.

As a HKS Machine Manufacturer, we focus on making that movement precise and repeatable. This is how designers and production teams can scale texture ideas into stable, saleable products. The goal is simple: set a pattern, run it at speed, and keep the hand feel and appearance consistent from roll to roll.

Three Guide Bars: Precision In Patterning

Our tricot knitting machine uses three guide bars. This is a practical sweet spot for textured pattern work.

- One bar can anchor the base structure, another can add lapping variation, and the third can enrich the surface with contrast or openness. With three bars, shogging sequences can be layered without losing stability.

- You can program short shogs to create tight, subtle textures. You can add longer shogs to form bolder relief.

- Each bar slides at defined distances, and the interplay between bars controls surface roughness and pattern clarity.

- For brands, this means more design freedom. For mills, it means fewer changeovers to achieve diverse looks.

As a HKS Machine Manufacturer, we help you lock in the right guide bar paths so the final fabric meets both design and production targets.

Advanced Needle System: Stitch Control for Texture

Textured fabrics depend on predictable stitch formation. Our advanced needle bar arrangement and compound needles create a clean, controlled loop. This matters at high speed and with complex shogging. When the loop forms the same way every time, the texture reads the same in every repeat. Compound needles reduce yarn stress and help place the loop accurately on the needle hook and closing element.

The result is even stitches and stable lapping geometry. For customers, that turns into practical gains: a fabric that looks right under store lighting and feels right in the hand. It also trims rework because stitch control lowers the chance of contour distortion. As a HKS Machine Manufacturer, we translate needle technology into texture reliability, so creative patterns do not become production headaches.

Tension Matters: Electronic Take-Up and Per-Beam Let-Off

Texture is not only about shogging. Tension control protects contour and hand feel. Our fabric take-up is electronically controlled to stabilize fabric draw. Each warp beam has a variable let-off device, so yarn tension stays accurate for every yarn system in the design. When take-up and let-off work together, the fabric does not warp or ripple. GSM stays consistent across the width and length. Tension control keeps textures defined and dye/finish responses consistent.

Resulting improvements:

- Reduced tension-related faults over long campaigns

- Consistent density for dependable pattern recognition

- Streamlined yarn and setting transitions

- Waste reduction via accurate contour formation

Impact: mills spend less time on recipes; brands see stable quality from sample to bulk.

Integrated Monitoring

Laserstop plus camera inspection deliver live quality visibility. Our machines integrate Laserstop and camera systems to watch the critical zones of knitting. If a yarn breaks, a loop mis-forms, or a guide bar moves off target, the system identifies it instantly. The machine can stop or alert. Operators address the source, not the symptom. This reduces waste because faults do not run on. It also keeps the texture uniform across the roll. You get better first-pass yield and more predictable delivery dates. Key benefits include:

- Defect detection at the moment of occurrence

- Stable pattern integrity throughout the batch

- Less waste and fewer customer complaints

As a HKS Machine Manufacturer, we design monitoring to support both speed and trust. It is more than a sensor; it is a quality workflow.

GrandStar® COMMAND and Energy Efficiency: Simple Control, Lower Costs

Setting shogging should be simple. Our GrandStar® COMMAND System is an advanced HMI that centralizes electronic settings. You can adjust guide bar shog distances, lapping sequences, take-up targets, and let-off profiles from a clear interface. Patterns become digital recipes. Operators learn faster. Changeovers are shorter.

Automation helps keep the machine in the right window while it runs. This cuts small drifts that erode texture detail. A speed-regulated drive system adds another advantage. It optimizes power use at different load and speed ranges. That is good for the environment and good for the cost per meter. You protect margins without slowing down.

If you are ready to turn shogging into a reliable texture portfolio, talk to Grand Star Technology. As a HKS Machine Manufacturer, we can review your current styles, suggest guide bar strategies, and run sample trials. Contact us to book a demo, request swatches, or plan a plant audit. Let’s make textured warp-knitted fabrics that sell, run efficiently, and meet your quality goals.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.