Essential Features in Carbon Fiber Multi Axial Machine

Carbon Fiber Multi Axial Machine capability sits at the heart of how Grand Star Technology delivers predictable output and quick setup for demanding composite programs. Our customers in wind power, cabin covers, and aerospace ask for stable fabric quality and a clean path to scale. We design and support machines that meet those real-world needs, not just brochure promises.

Engineered for Consistent Composite Fabrics

Consistency is the baseline for everything we build. Our Carbon Fiber Multi Axial Machine supports working widths of 2565 mm (101″) and 4496 mm (177″), so process engineers can match the layup window to the part – whether it’s a narrow spar cap or a wide shell panel. The E7 gauge promotes reliable loop formation, while a proven bar configuration keeps structure tight across the entire width: a compound needle bar, closing wire bar, knock-over sinker bar, supporting bar, counter retaining bar, and two ground guide bars. Together, these elements keep stitch geometry stable, which means fewer surprises in downstream infusion, less rework, and more predictable laminate properties.

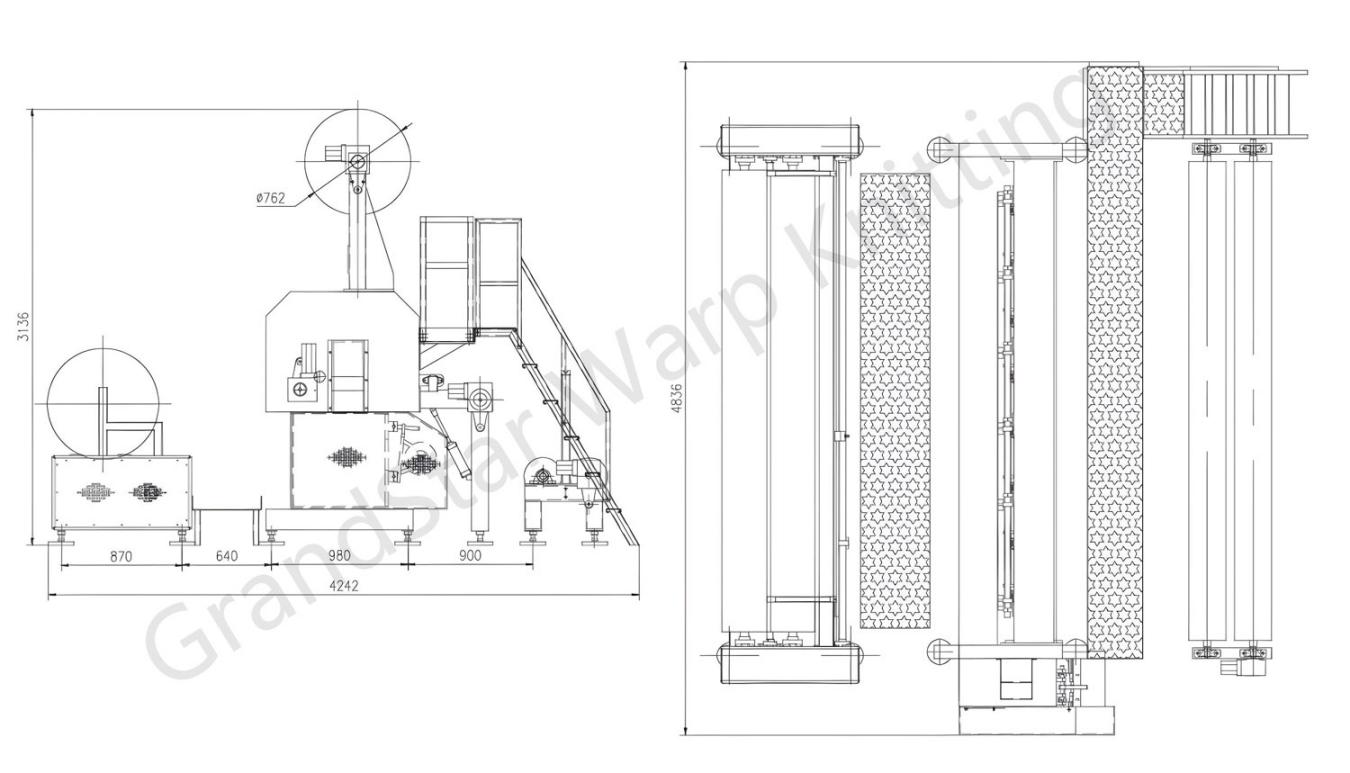

Dimensions and Gauge That Fit Real Projects

Projects rarely come in one size. By offering two standardized widths, we make it easier to balance throughput, waste, and fixture size. Plant managers appreciate that the same platform accommodates both development and volume production, reducing training overhead and spare-part complexity. The E7 needle selection offers a practical balance: strong enough for carbon fiber handling, gentle enough to protect yarn integrity as it moves through the machine.

Precision Control from Beam to Batch

When tension is steady, fabric quality follows. That’s why our control stack manages the whole path – from beam to take-up – so operators don’t have to fight with drift during long shifts.

- Yarn let-off: Each warp beam uses an electronically controlled drive with a geared motor and frequency converter to stabilize tension.

- Yarn stop motion (optional): Electronic sensing helps teams catch yarn events early, before they become scrap.

- Fabric take-up: Electronically controlled, with a geared motor and frequency converter to keep stitch density steady.

- Batching device: Stand-alone friction drive with pressure roller and max batch Ø 914 mm (36″), synchronized to stitch courses for clean, compact rolls.

For quick changeovers, the warp beam support provides two positions for sectional use with a max flange diameter of 30, preserving alignment and saving time between jobs.

Accurate Chopping, Weft Insertion, and Patterning

Edge control is where multi-axial reinforcement programs win or lose. We focus on repeatable placement so you can hold your laminate schedule without constant operator intervention. A servo-controlled chopper device (one unit per machine) builds consistent chopped layers that lay flat and bond well. The weft-insertion system is also servo controlled, placing fibers accurately across the full width. Patterning is handled by an N-drive with pattern disc and an integrated tempi change gear drive, using 1 pattern disk for reliable, repeatable results.

This is more than a spec sheet. It’s about clean laydowns and predictable drape on tight contours – vital for wind blade sections, cabin covers, and aerospace skins where small deviations turn into costly rework. If you are scanning the market for a chopped biaxial warp knitting machine, consider how tightly the control loop is closed. Precise control reduces fiber waviness, limits bridging on edges, and helps you hit target areal weights with fewer adjustments.

❓ Why Servo Control Matters on the Edge

Speed is important, but consistency under speed is what protects your margin. Servo control gives you the fine adjustment needed for delicate carbon tows and changing environmental conditions. It helps maintain alignment at the selvage, reduces variation across the width, and supports faster restarts after planned stops. In short, a servo-controlled weft insertion system protects both quality and uptime – two metrics that show up clearly in your monthly reports.

Power, Uptime, and Service You Can Count On

Every Carbon Fiber Multi Axial Machine we ship includes a control backbone that operators can learn quickly and maintenance teams can trust. A machine control computer coordinates the main drive, yarn feeding, and fabric take-up. Operators work through a touch screen in the switch cabinet, with live production data at a glance for shift handovers and audits. Under the hood, the electrical system is speed-regulated, power-failure safe, and includes inching motion for safe threading and inspection. A single speed control for core functions, implemented with frequency converters, keeps the setup simple and repeatable. For longevity, immersion lubrication in the crankcase with filtration reduces wear on moving parts.

✅ Power scales with the manufacturing window you choose:

- 2000-4400 mm widths: 13 kW

- 4400-6000 mm widths: 18 kW

This gives your line headroom for dense programs without oversizing for smaller parts. It also simplifies energy planning and makes it easier to align with plant-wide efficiency goals.

✅ Operating Environment and Installation Notes

Stable outcomes require stable surroundings. The recommended environment is 25 °C (±2 °C) at 65% relative humidity, with control of drafts and protection against dust and fiber fly. Plan for a floor load of 2000-4500 kg/㎡ depending on machine type and length, and account for operational vibrations during installation. These practical steps help keep the surface clean, the bearings healthy, and the fabric on spec during long campaigns.

✅ Training and After-Sales Support

Technology only pays off when teams can use it well. Grand Star Technology delivers installation and training through multiple formats: detailed professional manuals, online guidance, a curated video library, and on-site sessions tailored to your team. We have delivered on-site training in 20+ countries and maintain local service teams in Turkey, India, Vietnam, Indonesia, and the USA. Where a local team is not yet in place, we provide real-time online support first; if needed, we dispatch engineers from the nearest hub for hands-on assistance.

Our proactive customer care program includes regular visits every 1-2 months. Engineers review machine performance, advise on maintenance, and help sustain stability at speed. This rhythm cuts unplanned downtime and protects the long-term value of your Carbon Fiber Multi Axial Machine.

Call to Action

Looking to validate the Top Features of Carbon Fiber Multi Axial Machine against your current part mix? Contact Grand Star Technology for a technical consultation, sample fabric runs, or a detailed specification review. We’ll help you align width, gauge, patterning, and servo control with your composite program – so you can move from trials to production with confidence.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.