Chopped Biaxial Warp Knitting Machine: Features You Should Know

The Chopped Biaxial Warp Knitting Machine is reshaping composite fabric production. It brings stable tension, clean layup, and fast changeovers. Operators see results in fewer defects and smoother batching. Engineers see tighter tolerances and repeatable patterns. Energy use stays balanced while output scales. But the real edge isn’t only in speed or width. It’s in how a few hidden systems work together to protect quality when conditions shift. What are they, and why do they matter in wind power and aerospace? Read on to see the features most teams overlook – and how they change your yield curve.

Built For Composite Success

Scaling production for wind components, cabin covers, or aerospace laminates exposes one simple truth: variation is expensive. Our Chopped Biaxial Warp Knitting Machine is engineered to keep variation out of your fabric and off your balance sheet.

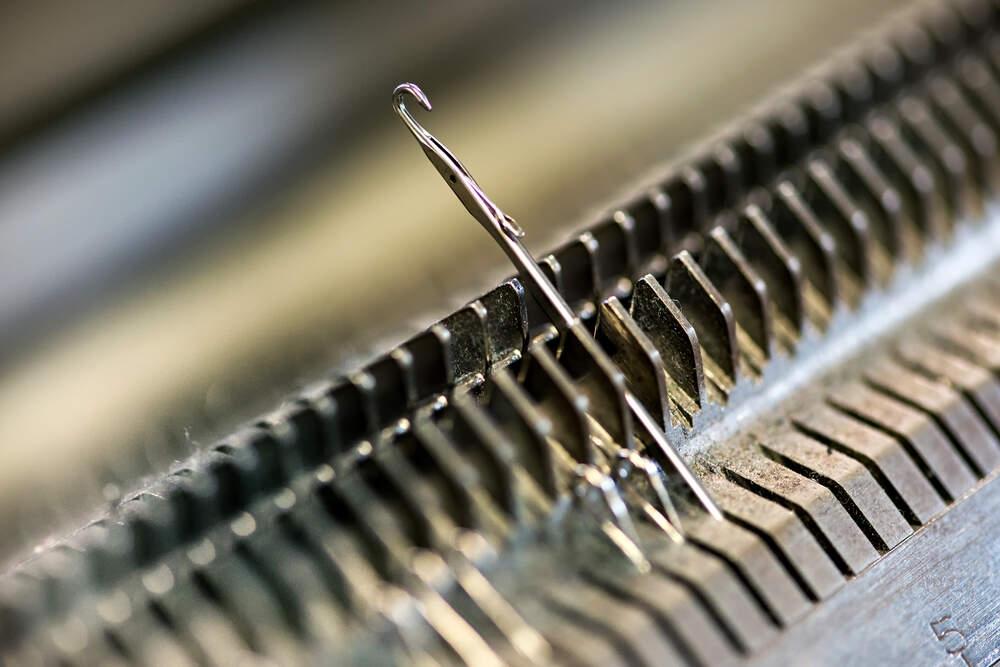

Two working widths – 2565 mm (101″) and 4496 mm (177″) – cover typical composite layup formats without awkward splicing. An E7 gauge provides the stitch density needed for structural plies while maintaining throughput for longer runs. The knitting heart combines a compound needle bar, closing wire bar, and knock-over sinker bar, stabilized by a support bar, counter-retaining bar, and two ground guide bars. In practice, this layout yields flat, uniform biaxial fabrics with a predictable chopped layer, helping downstream resin infusion proceed smoothly.

Pattern integrity matters as much as speed. An N-drive with pattern disc and integrated tempi change gear keep patterning consistent from roll to roll. Operators manage production through a machine control computer and a touchscreen HMI mounted in the switch cabinet, with real-time data on drive status, yarn feed, and take-up. Supervisors see what the machine is doing and can make adjustments fast – without stopping the line longer than necessary.

✅ Servo Accuracy Where It Counts

Two subsystems make the difference between “good enough” and “ready for certification”: the servo-controlled chopper and servo-controlled weft-insertion. Precise chop length and weft placement tighten dimensional tolerances, which is essential in aerospace and in biaxial warp knitting for wind turbine blades where laminate symmetry and repeatability drive approval.

What Sets It Apart On The Line

Downtime, inconsistent tension, and messy batching are the classic pain points in composite textiles. We tackled each one at the source.

- Independent Electronic Yarn Let-Off- Each warp beam position uses a geared motor with a frequency converter. Tension remains stable across material changes and long runs, which directly reduces scrap.

- Electronic Fabric Take-Up- A matched geared motor and frequency converter keep stitch courses steady. That means cleaner edges and fewer defects at roll ends.

- Sectional Warp Beam Support- Two beam positions, built for flanges up to Ø 30, let you mix fiber types or swap beams quickly when styles change.

- Optional Electronic Yarn Stop Motion- Early break detection prevents latent defects from creeping into premium rolls.

- Standalone Batching- Friction-drive with pressure roller, max batch Ø 914 mm (36″), synchronized to stitch course flow for tidy, stress-free winding that stores well and unwinds cleanly at prepreg or layup.

- Speed-Regulated Main Drive- Frequency-converted, smooth acceleration with inching motion for threading and maintenance; fewer jolts, less fabric shock.

- Right-Sized Power- 13 kW for 2000- 4400 mm machines; 18 kW for 4400 – 6000 mm machines. Enough torque for composites, without energy overspend.

- Immersion Lubrication- Oil-bath crankcase with filtration reduces wear, helps hold alignment, and lowers noise.

✅ Operator Experience, Simplified

- Touchscreen HMI consolidates controls and displays production data plainly.

- Single-speed control for core functions streamlines training.

- Power-failure-safe logic preserves machine state, protecting in-process fabric.

✅ Built For Real Factory Conditions

The machine is happiest at 25 °C ±2 °C and 65% RH. Avoid drafts, dust, and fiber fly to keep yarn paths clean and surfaces true. Plan for floor loads of 2000 – 4500 kg/m² depending on machine size and allow for operational vibration in your base design. These are not just installation notes – they are the guardrails for stable, certifiable output.

❓ Why These Details Reduce Risk

- Tension stability = fewer downstream defects. Consistent let-off and take-up prevent skewed angles and variable areal weights that lead to rejected parts.

- Servo governance = tighter tolerances. When chop length and weft angle are repeatable, infusion and cure windows widen, not narrow.

- Clean batching = cleaner subsequent processes. Rolls that wind evenly also unwind evenly, which reduces wrinkles during cutting and layup.

Applications, Payback, And How We Support You

Customers choose the Chopped Biaxial Warp Knitting Machine when the laminate has to be right the first time.

Wind power gains from the larger working width, which suits blade skins and nacelle structures. Edge quality and roll consistency cut rework during cutting and preforming. Cabin covers benefit from predictable chopped layers that adapt to curved surfaces without print-through. In aerospace, every ply must trace back to stable parameters; our drive system, patterning, and HMI give you that audit trail.

In day-to-day operations, three outcomes matter most:

- Higher First-Pass Yield. Electronic let-off, controlled take-up, and accurate chop/weft placement mean fewer defects, fewer restarts, and tighter CoQ (cost of quality).

- Faster Changeovers. Sectional beams and a clear HMI reduce setup time when switching fibers or styles; training new operators is straightforward.

- Quality You Can Certify. N-drive repeatability and tempi gear integration lock in pattern fidelity for sectors that require documented consistency.

The payback goes beyond scrap savings. Stable textiles accelerate downstream steps – nesting, cutting, layup, infusion, and cure – because your plies behave the same from the core of the roll to the tail. That predictability de-risks schedules, a real advantage when contracts carry penalties for late delivery.

✅ Our Commissioning Playbook

We ship the machine ready for production, but we also bring process discipline. During installation, our engineering team aligns environmental conditions, verifies floor load support, and tunes the frequency drives to your typical recipes. We map operator workflows on the touchscreen HMI so the interface mirrors your SOPs. Finally, we train maintenance teams on immersion lubrication checks and inching procedures to keep uptime high.

See It Run On Your Material

If you want proof on your yarns and your patterns, request a demo roll from Grand Star Technology. We’ll configure the Chopped Biaxial Warp Knitting Machine – width, gauge, bars, drive, batching – to your spec and share tailored run data. Prefer a deeper dive? Ask for our application note on servo-controlled weft insertion for composite laminates and a line-by-line ROI model for your plant.

Ready to start? Contact Grand Star Technology for a quote or a technical consultation. Let’s turn stable textiles into faster certifications – and stronger, lighter parts.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.