How the Chopped Stitch Bonding Machine Cuts Costs and Time

In a quiet textile factory on the edge of Suzhou, production lines were falling behind. The machines kept running, but deadlines kept slipping. Mr. Liu, the factory manager, watched his workers push through long shifts, yet the output wasn’t enough. Rising labor costs and growing material waste were cutting deep into the margins. Pressure from clients was building. That’s when Mr. Liu first heard about the Chopped Stitch bonding machine – a new solution that promised faster, cleaner, and more efficient production. He wasn’t sure it would work. But with profits shrinking, he had to take the risk.

Then came a visit to a trade show in Shanghai, where a sleek new machine caught his eye: the Chopped Stitch Bonding Machine. The rep said it could reduce stitching time by nearly half. It sounded too good to be true. But Mr. Liu was curious.

Back at the factory, the team ran a trial. What happened next surprised even the most skeptical engineers.

So, how exactly did this machine change everything? And what does it mean for the future of textile production? Let’s take a closer look.

Introducing the Chopped Stitch Bonding Machine

Overview of Product Capabilities

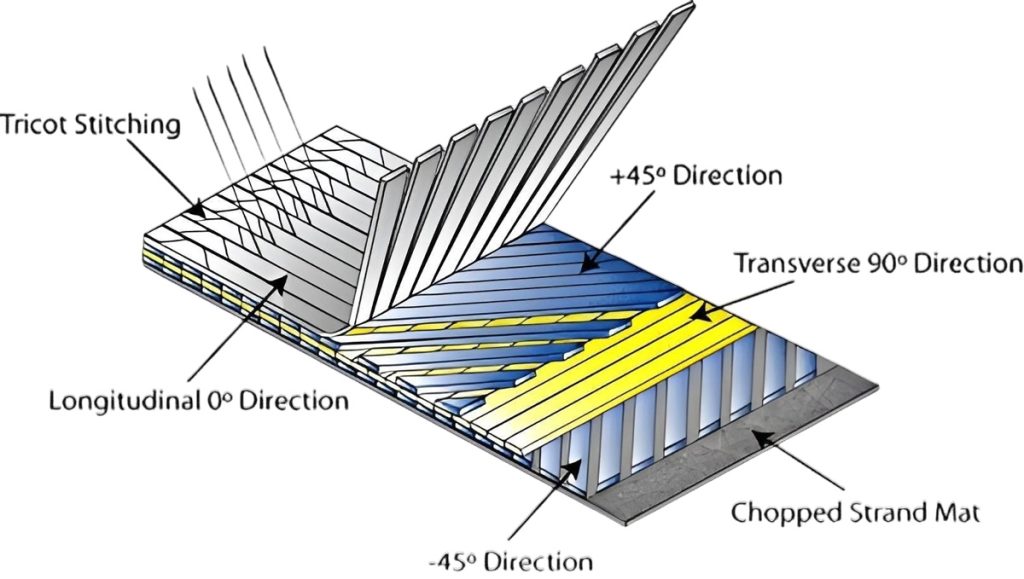

The Chopped Stitch bonding machine uses modern bonding methods to replace old stitching techniques. It creates a smooth, strong bond across a variety of fabrics. This method is ideal for nonwoven textiles. It reduces mechanical stress on the fabric, which improves quality and durability.

The Efficiency Edge

This machine works faster than traditional stitchers. It lowers energy use and reduces fabric waste. Less manual labor is required, which means fewer errors and better consistency. The result? Lower production costs and higher profit margins. The Chopped Stitch bonding machine pays for itself quickly through time and cost savings.

Designed for Today‘s Market

Today’s textile industry moves fast. Factories need equipment that can handle short runs and frequent changeovers. The Chopped Stitch bonding machine is built for flexibility. It offers steady performance with minimal downtime. This makes it a smart choice for any forward-thinking manufacturer.

Flexible Sizing for Any Operation

Working Widths to Fit Every Floor Plan

The Chopped Stitch bonding machine comes in multiple width options: 2000mm, 2800mm, 3600mm, 4400mm, 4800mm, 5400mm, and 6000mm. This allows factories of all sizes to choose a model that fits their space and output needs. Smaller setups can start with a compact version, while large plants can scale up.

Gauge Variability for Product Customization

Different textiles require different levels of precision. That’s why the machine offers gauge options from F7 to F22. This range gives users the ability to produce both fine and heavy-duty materials. Whether it’s medical fabrics or industrial layers, the Chopped Stitch bonding machine handles it with ease.

Scalable for Growth

As business grows, so should your machinery. This bonding machine supports easy upgrades. You can adjust your working width or change gauge settings based on customer needs. It’s a long-term investment with the flexibility to adapt to future demand.

High-Precision Mechanics

Knitting Elements & Pattern Drive

The Chopped Stitch bonding machine uses advanced knitting elements for better performance. It includes a compound needle bar, closing wire bar, knock-over sinker bar, and supporting bars. These parts work together to create clean, stable bonds across many fabric types. The machine’s structure ensures steady stitching, even at high speeds. This results in smooth and accurate production every time.

Intelligent Pattern Drives

Pattern control is a key feature of the Chopped Stitch bonding machine. It uses an NN-drive with a pattern disc system. This drive allows for precise movements during bonding. An integrated tempi change gear supports quick pattern adjustments. This helps factories save time during setup and improves overall machine flexibility.

Enhanced Flexibility with Single Disc

A single pattern disc makes the machine easier to manage. Switching between production runs takes less time. There is no need for complicated changes or adjustments. With the Chopped Stitch bonding machine, operators can shift from one design to another quickly. This feature is ideal for manufacturers handling different product lines.

Smart Yarn and Fabric Handling

Warp Beam, Yarn Let-Off, Take-Up & Batching

This machine supports 1 or 2 warp beam positions for better setup flexibility. It handles a flange diameter of up to 30 inches. The beam design ensures a steady feed of yarn without breaks. This makes the Chopped Stitch bonding machine suitable for continuous production and bulk orders.

Precision Yarn Control

Yarn feeding is fully electronic. The machine features a yarn let-off system with a geared motor. A frequency converter provides accurate tension control. An optional yarn stop-motion system helps prevent defects. This setup reduces material waste and improves fabric quality. Every meter of fabric stays consistent.

Consistent Fabric Take-Up & Batching

The fabric take-up system is also electronically managed. A geared motor with a frequency converter ensures smooth winding. Batching is handled by a friction drive with a pressure roller. It supports a maximum batch diameter of 914mm (36 inches). These features allow the Chopped Stitch bonding machine to deliver clean, rolled fabric with minimal defects.

Advanced Control Systems

Motion Control, Interface, and Electricals

The machine is controlled by a central computer system. It manages the main drive, yarn feeding, and fabric take-up. This unified control reduces errors and keeps everything in sync. The Chopped Stitch bonding machine delivers consistent results across long production cycles.

User-Friendly Interface

The interface uses a touchscreen design. Operators can see real-time data, including speed, pattern, and output levels. Adjustments can be made easily without stopping the machine. This makes the machine ideal for factories that want both performance and simplicity.

Reliable Power and Safety

The machine uses a speed-regulated drive with power-failure safety functions. There is a single-speed control for the main functions, powered by a frequency converter. Motor options range from 13KW (for 2000mm–4400mm width) to 18KW (for 4400mm–6000mm width). The Chopped Stitch bonding machine is both powerful and safe.

Support, Service & Legacy

Installation, Global Support & Brand Trust

Installation is easy with help from professional manuals and training videos. On-site and online support are available to ensure smooth onboarding. The Chopped Stitch bonding machine is backed by detailed instructions and responsive service teams. This reduces downtime during setup and training.

Global Service Network

In regions without local service centers, Grand Star offers real-time online support. When on-site help is needed, engineers are dispatched from the nearest hub. This ensures fast and efficient service. The goal is to keep every Chopped Stitch bonding machine running at peak performance.

Grand Star Technology & Partners

Grand Star Technology has been a leader in warp knitting innovation since 2012. The company follows strict quality systems like ISO9001:2000. Trusted partners include top global brands such as Groz-Beckert, SKF, Schneider Electric, and Mitsubishi. Our support ensures that every machine is built to the highest standard.

Experience Smarter Stitching – Request a Demo Now

Upgrade to the Chopped Stitch bonding machine and experience faster output, lower costs, and superior fabric quality. Whether you’re scaling up or modernizing your operations, this machine delivers the performance today’s textile market demands. Don’t let outdated equipment slow you down. Contact us today for a quote, demo, or expert consultation – your next big improvement starts here.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.