Chopped Strand Mat Machine Applications in Composites Industry

Chopped Strand Mat Machine Applications in Composites Industry are reshaping how factories hit quality, speed, and cost goals. A Chopped Strand Mat Machine delivers steady mat weight and clean layup. It cuts waste. It keeps cycle times predictable. Marine, wind, and building products all benefit. Auto interiors do, too. Yet the real story is not only efficiency. It is how small engineering choices unlock big wins on the shop floor. Which settings matter most? Where do plants actually see ROI in month one? Stay with us – what comes next may change your production plan.

Where Chopped Strand Mat Machine Lines Create Real Value

The composites sector is under pressure to deliver consistent quality, lower scrap rates, and stable cycle times. A Chopped Strand Mat Machine helps teams meet those targets by supplying a uniform, drapable reinforcement for open-mold, compression-mold, and infusion processes. In marine, steady mat weight improves hull layup and reduces post-cure rework. In wind energy, predictable mat architecture supports larger blades and tighter tolerance on mold closure. Construction fabricators rely on the same stability for panels, covers, and structural skins, where repeatable resin uptake limits part-to-part variation.

For automotive programs, CSM supports rapid tool changes and complex geometries. The random fiber orientation contributes to multi-directional strength, while the mat conforms to ribs and corners without heavy handwork. Across these segments, the business impact is direct: less operator intervention, smoother downstream molding, and fewer off-spec parts. That is exactly where our equipment earns its keep.

- Marine And Wind Energy Use Cases

Boatbuilders use CSM for skin coats, stringers, and bulkheads. Wind blade makers combine CSM with stitched fabrics to balance surface finish and laminate toughness. With steady mat supply, teams can scale from prototyping to volume without rewriting process windows.

- Automotive And Construction Programs

Interior modules, ducts, roofing skins, and utility enclosures benefit from the mat’s formability. A stable Chopped Strand Mat Machine feed reduces variability in demold times and cuts secondary finishing, which keeps takt time predictable.

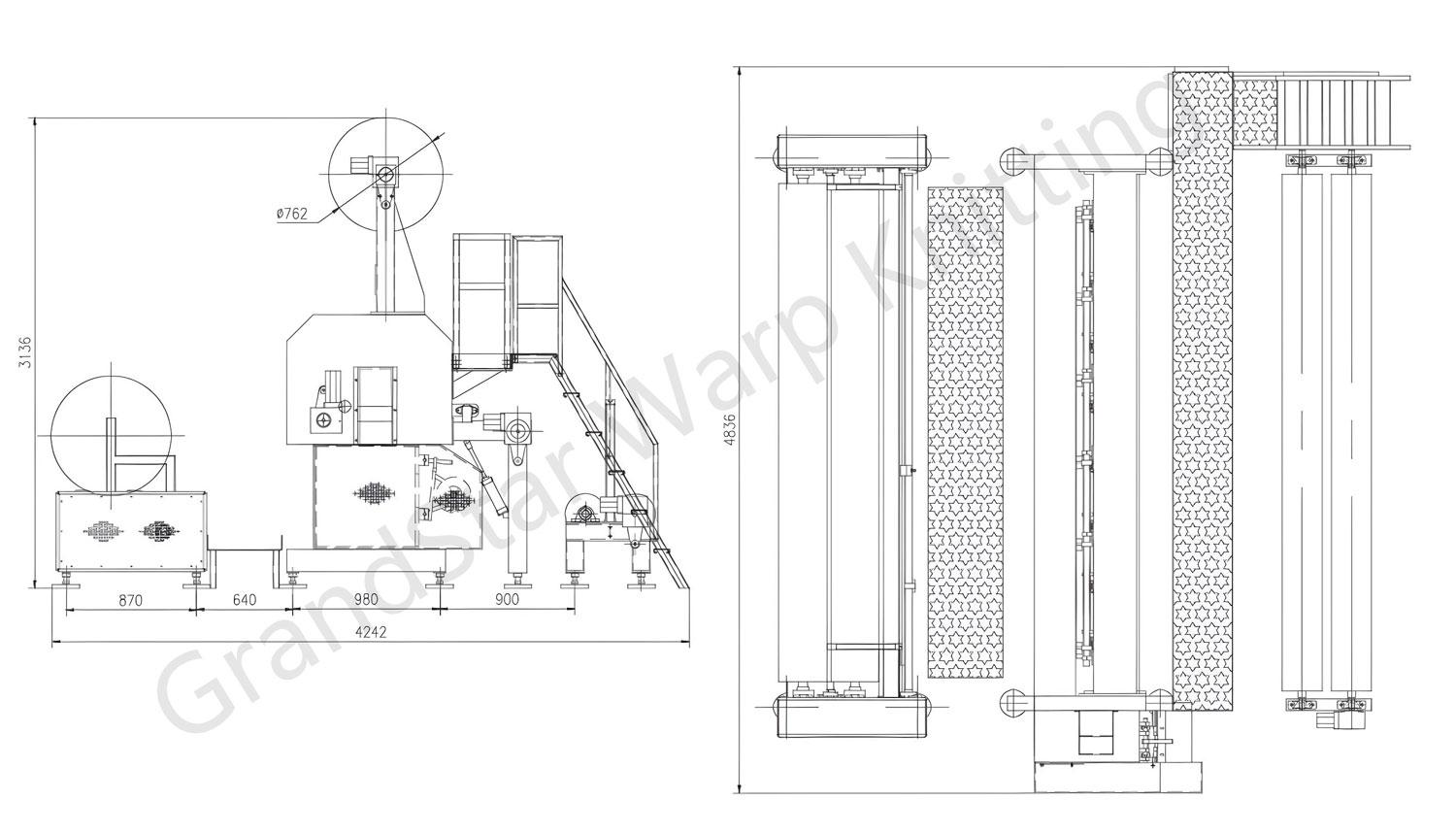

Inside The Equipment: Grand Star Technology Capabilities

Our perspective is simple: the best Chopped Strand Mat Machine is the one that stays in spec, shift after shift. That is why we engineer robust motion control, precise yarn handling, and clear operator feedback across the line.

- Working Widths You Can Build Around

We support 2565 mm (101″) and 4496 mm (177″) formats to match common composite panel and roll sizes, so planners can align slit-to-width strategies without added waste.

- Stable Loop Formation And Guidance

With E7 gauge and a full bar set – compound needle bar, closing wire bar, knock over sinker bar, supporting bar, counter retaining bar, and 2 ground guide bars – the fabric path stays controlled, which supports uniform reinforcement laydown.

- Patterning And Drive Control

Our N-drive with pattern disc and integrated tempi change gear drive keep pattern accuracy tight with one pattern disk, while the control computer coordinates main drive, yarn feeding, and take-up for repeatable output.

- Warp And Weft Management

Two warp beam positions (max flange Ø30) provide sectional flexibility. Electronically controlled yarn let-off and electronically controlled fabric take-up, each with geared motors and frequency converters, synchronize tension across the machine. Weft insertion and one chopper device, both servo-controlled, maintain cut accuracy and distribution.

- Batching And Operator Interface

A separate batching unit with friction drive by pressure roller handles rolls up to Ø914 mm (36″). Operators monitor production via a touch screen in the switch cabinet, with production data available at a glance.

- Power, Protection, And Reliability

Speed-regulated drives are power-failure safe and include inching motion for safe threading. Main motor power is matched to width: 13 kW for 2000 – 4400 mm, 18 kW for 4400 – 6000 mm. Immersion lubrication with filtration supports long service intervals. Recommended operating conditions are 25 °C (±2 °C) and 65% RH, in clean, low-draft environments with appropriate floor load and vibration control.

Why it matters: these hardware choices are not academic. They trim the root causes of mat variability – tension drift, pattern slip, and inconsistent chop – so downstream molding stays predictable. When you are running a fiberglass mat production line, predictability is profit.

What You Can Expect From A Grand Star Chopped Strand Mat Machine

- Consistent mat architecture for fewer molding surprises

- Clear operator feedback to shorten training time

- Coordinated motion control that holds tension and chop accuracy

- Service pathways that match your geography and production risk

- A roadmap to scale- without rewriting your process every quarter

Call To Action

If you are exploring a new composites line – or need to stabilize an existing one – talk to our team. Grand Star Technology can size a Chopped Strand Mat Machine to your width, throughput, and quality targets, then stand behind it with training and proactive care. Contact us to schedule a technical review and receive a tailored proposal for your next composite program.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.