A Smart Guide to Picking a Tricot Warp Knitting Machine

In the world of textile manufacturing, choosing the right Tricot Warp Knitting Machine isn’t just about speed or price – it’s about finding a machine that truly fits your fabric goals. Whether you’re producing delicate lace, strong upholstery fabrics, or stretchable sportswear, the right machine configuration makes all the difference. So, how do you pick the perfect one for your needs? Let’s break it down in a practical, no-fluff way.

One Size Doesn‘t Fit All

When investing in a Tricot Warp Knitting Machine, one of the most critical decisions you’ll make is choosing the right number of guide bars. While this may sound technical, it directly impacts the structure, elasticity, and overall design capability of the fabrics you’ll produce. Whether you’re manufacturing functional textiles or fashion-forward designs, your choice of machine configuration can determine both the creative possibilities and the efficiency of your production line.

In tricot knitting, guide bars control the movement of yarn to form the loops and patterns in the fabric. Each additional bar increases the complexity and range of patterns that can be created, opening the door to new applications – but also introducing more technical requirements. Here’s a breakdown of what each configuration typically offers:

✅ 2 Guide Bars

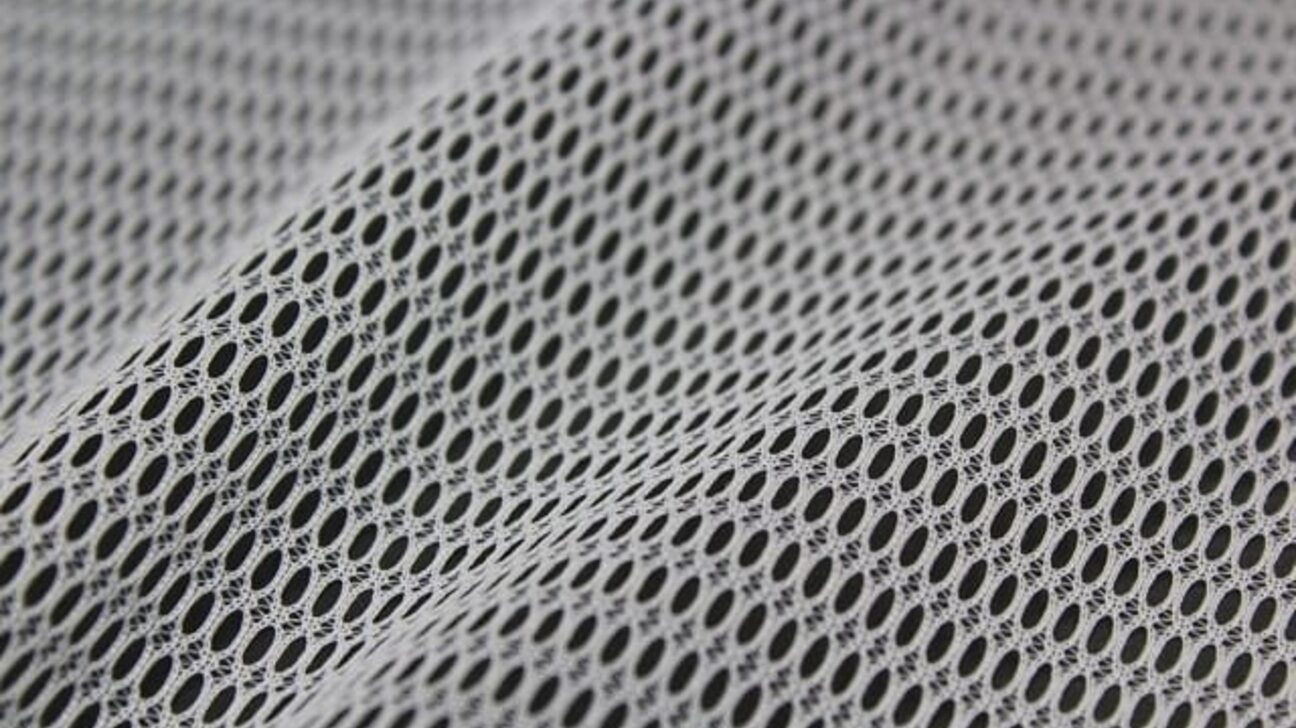

These machines are best suited for straightforward, large-scale production. They’re perfect for creating lightweight and stable textiles such as mosquito nets, tulle, and coating backings. Because of their simple operation and lower energy consumption, they are ideal for companies looking to minimize production costs while maintaining high output. If your focus is on uniform, non-elastic fabrics that don’t require elaborate designs, this is a practical and highly efficient option.

✅ 3 Guide Bars

Stepping up to three guide bars provides more flexibility in both pattern and fabric structure. These machines are a great fit for stretchable fabrics used in sportswear, automotive interiors, toy plush materials, and upholstery. The additional bar enables more complex overlapping movements, allowing for increased fabric performance in terms of stretch and durability. For manufacturers who need a balance between creativity and production scalability, this configuration hits the sweet spot.

✅ 4 Guide Bars

If you’re producing high-end, functional, or textured textiles, machines with four guide bars offer unmatched design versatility. They allow for pile structures, intricate textures, and multi-layered fabrics often found in premium footwear, cleaning cloths, home decor, and technical textiles. These machines enable the creation of fabrics with added depth and dimension, appealing to industries that demand both aesthetic and performance excellence.

However, more guide bars don’t automatically mean a better machine for your business. Increased complexity can lead to higher maintenance requirements, greater energy use, and a steeper learning curve for operators. That’s why it’s essential to consider your current production needs as well as your long-term growth plans.

In short, choosing the right Tricot Warp Knitting Machine configuration isn’t about picking the most advanced model – it’s about selecting a machine that aligns with your product line, budget, and manufacturing capabilities. Understanding how guide bars influence fabric construction helps ensure that your investment supports not only what you’re producing today but also what your customers may demand in the future.

Performance You Can Rely On

As someone who’s worked with various textile manufacturers, I’ve learned one thing: reliability matters just as much as features. At Grand Star, we’ve spent years listening to client feedback and refining our machines to offer both performance and ease of use.

Let’s take a look at what truly sets our Tricot Warp Knitting Machines apart.

We’ve designed our systems with versatility in mind. You can fine-tune stitch density and fabric gauge depending on the project – whether that’s airy mesh or tight, heavy-duty fabric. Our machines give you the power to adapt on the fly, which is crucial in today’s fast-changing market.

² Key Highlights

- Electronic yarn let-off systems that help keep tension just right- even at high speeds.

- Compound needle technology for better stitch definition and richer fabric texture.

- Auto-adjusting take-up systems that maintain perfect balance during production.

Also, we’ve integrated real-time monitoring into many of our models. Laser sensors and smart cameras detect issues as they happen, so you can avoid waste and rework. This not only boosts quality but also reduces material loss – something every production manager can appreciate.

What’s more, our GrandStar® COMMAND SYSTEM makes operation surprisingly simple. The touchscreen HMI lets users control and fine-tune electronic settings intuitively, reducing the learning curve even for new operators.

Why Grand Star?

Since launching in 2012, we at Grand Star Technology have committed ourselves to being more than just a manufacturer. We see ourselves as partners in our clients’ success. From our base in Fujian, China, we’ve built relationships with customers across the U.S., Japan, India, Turkey, and beyond.

What makes us different? We combine cutting-edge technology with an understanding of real-world manufacturing. Our Tricot Warp Knitting Machines aren’t built in isolation – we collaborate closely with fabric developers, designers, and factory managers to ensure our machines meet the needs of modern textile production.

Our clients use our machines to create:

✅ Stretchable sportswear fabrics that hold up under pressure

✅ Soft, breathable materials for intimate apparel and lingerie

✅ Durable shoe textiles that withstand daily wear

✅ Plush, pile fabrics for toys and premium upholstery

✅ High-function technical fabrics for industrial and automotive use

Every machine is tested rigorously before it leaves our floor, and our support doesn’t stop after delivery. We offer ongoing technical assistance and customization, ensuring our clients always stay ahead.

Final Words

Selecting a Tricot Warp Knitting Machine is not a one-size-fits-all decision. It’s about aligning machine capability with your production vision – whether that means mass-producing consistent mesh fabrics or creating specialized, textured knits for luxury products. Take the time to think about what kinds of fabrics you want to make – now and in the future. Then, consider the guide bar configuration, performance flexibility, and technical support you’ll need to get there. At Grand Star, we don’t just provide machines – we deliver solutions, crafted with care and backed by experience. So, if you’re ready to make an informed choice and bring greater innovation to your fabric line, we’re here to help you find the perfect fit.

Let‘s create the future of textiles – one stitch at a time.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.