What Are the Types Of Warp Knitting Needles

When it comes to warp knitting, the needle is more than just a tool – it’s the heart of the process. From sportswear to automotive fabrics, the type of needle used can affect speed, quality, and even fabric texture. But did you know there’s more than one kind?

Each type of warp knitting needle serves a specific purpose. Some are built for speed. Others are made for precision or working with delicate yarns. Choosing the right one can change everything.

So, what are the different types of warp knitting needles? And how do they work in real-world applications? If you’ve ever wondered what sets latch needles apart from compound or bearded needles – you’re in the right place.

Let’s dive into the world behind the threads. The answers might surprise you.

The Role of Needles in Warp Knitting

Why Needles Matter

In warp knitting, the needle plays a key role. It directly affects fabric texture, loop formation, and production speed. A small change in the needle type can lead to big differences in fabric quality. This is why choosing the right warp knitting needles is essential.

Understanding Warp Knitting Machines

Warp knitting machines come in different types, like tricot and Raschel. Each type uses different needles depending on the fabric being made. For example, tricot machines focus on speed and precision, while Raschel machines allow for more complex structures. Knowing the machine helps determine which warp knitting needle is best suited.

Types vs. Applications

Different needles serve different purposes. Some are designed for strength, others for flexibility or fine detail. The type of warp knitting needle must match the specific application. This ensures the fabric is not only strong but also meets design and texture goals.

Common Types of Warp Knitting Needles

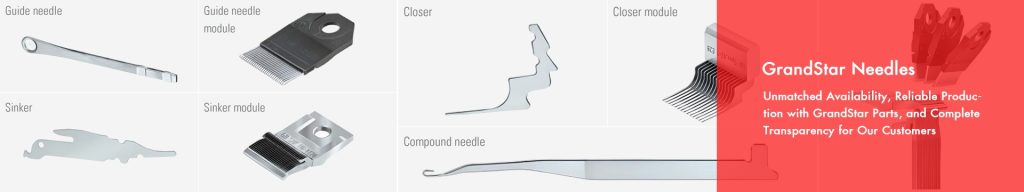

Guide Needles

Guide needles help position yarns accurately. They are often used in Jacquard and Pattern Bar systems. These warp knitting needles ensure each yarn follows the correct path, allowing for intricate patterns and consistent results.

Compound Needles

Compound needles have two parts that work together to form loops. They allow for more controlled and flexible movements. These needles are ideal for high-speed production where accuracy is critical. They are a popular choice in both tricot and Raschel knitting.

Sinker Needles

Sinker needles support the yarn during the knitting process. They hold the fabric in place and assist in loop formation. Tricot machines use sinker modules for precise control, while Raschel machines use a wider variety for support. In the next section, we will take a closer look at the sinker needle, one of the most important components in warp knitting.

In Focus – The Sinker Needle

Introduction to Sinker Modules

Sinker modules are essential in many warp knitting machines. They help control the position of the yarn and maintain stability during knitting. In tricot machines, sinkers play a major role in producing smooth, high-quality fabrics. Raschel machines use a variety of sinkers, each with a different support function.

Functions of the Sinker Needle

The sinker needle has several key functions. It holds and guides the old loops while new ones are formed. It also adjusts the depth of the yarn’s bend, which affects the texture. In some machines, the sinker helps control loop length and density for better fabric structure.

Why Choose Grand Star Sinker Modules

Grand Star Technology offers top-quality sinker needles for warp knitting. Our products are made with durable materials and precision design. This means less downtime, better fabric quality, and longer machine life. Whether you’re producing sportswear or technical fabrics, Grand Star sinker modules help deliver top performance.

Specialized Needles for Jacquard and Pattern Bar Systems

Guide Needle for Piezo Jacquard

Piezo Jacquard systems are known for their ability to create detailed, multicolor patterns. The guide needle for piezo Jacquard helps control each yarn path with speed and accuracy. These warp knitting needles are ideal for applications where design precision is critical, such as lace or decorative fabrics.

Guide Needle for Pattern Bar

Pattern bar systems rely on accurate yarn movement. The guide needle for pattern bar ensures that each yarn follows the intended route. These warp knitting needles are used to produce complex structures where control and stability are required. They are widely used in Raschel machines.

Retaining Pin & Closing Wire

Retaining pins and closing wires are small but important parts. They support the function of warp knitting needles by helping lock in stitches. These components help maintain the shape of the fabric and are often used in Jacquard and pattern knitting. Without them, loop stability would be hard to achieve.

Stitch Bonding Needle Solutions

Compound Needle for Stitch Bonding

Stitch bonding combines warp knitting with nonwoven layers. The compound needle for stitch bonding is made to handle these thick structures. It creates tight bonds between layers, ensuring strength and durability. These warp knitting needles are crucial in industries like automotive and filtration.

Guide Needle for Stitch Bonding

In stitch bonding, yarn placement must be exact. The guide needle for stitch bonding helps position yarns across layers with precision. These warp knitting needles are used in high-speed operations where consistent yarn handling is required.

Sinker & Retaining Parts for Stitch Bonding

Sinkers, retaining pins, and knock-over sinkers are used together during stitch bonding. They stabilize the yarn and keep the fabric layers aligned. These parts work alongside warp knitting needles to improve fabric strength and shape. They are essential in bonding operations that require reliability and control.

Introducing Grand Star Technology

Our Mission and Global Reach

Since 2012, Grand Star Technology has focused on innovation in warp knitting. We provide advanced warp knitting needles and parts that improve productivity and reduce waste. Based in Fujian, China, we serve customers in the United States, Japan, Turkey, India, Vietnam, and more.

Precision Engineering, Proven Results

Grand Star products are built with care and attention to detail. From guide needles to sinkers, our warp knitting needles are tested for precision and durability. This helps our clients produce better fabric with fewer interruptions.

Why Leading Manufacturers Choose Grand Star

Top textile companies choose Grand Star because we combine quality, service, and innovation. Our warp knitting needles and accessories are designed to meet modern demands. We help customers stay competitive in a fast-changing global market.

Choosing the Right Needle for Your Application

Needle Selection by Machine Type

Not all needles work in every machine. Tricot, Raschel, and stitch bonding machines each require specific types of warp knitting needles. Choosing the right needle ensures smooth operation and better fabric output.

Performance Factors to Consider

Needle type affects fabric strength, loop density, and production speed. It’s also important to consider yarn type and fabric design. The right warp knitting needle improves both quality and efficiency.

Grand Star‘s Commitment to Innovation

At Grand Star, we invest in research and development. Our goal is to improve warp knitting needles for today’s and tomorrow’s textile needs. We continue to create solutions that meet industry challenges while supporting sustainability.

Join Global Leaders in Warp Knitting Innovation

Ready to take your textile production to the next level? Grand Star Technology offers high-quality warp knitting needles designed for precision, speed, and durability. Whether you’re producing fashion fabrics, technical textiles, or nonwoven materials, we have the right solutions for your machines. Join industry leaders around the world who trust Grand Star for innovation and performance.

Contact us today to find the perfect warp knitting needles for your application!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.